OPTICAL INTERCONNECTS: Flexible evanescent coupler eases backplane connections

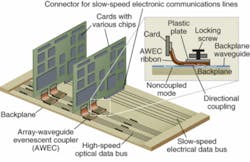

Interconnects for card-to-backplane connections and motherboards will soon be required to handle multigigahertz speeds as computing power increases; however, electronic interconnects become overwhelmingly complex and expensive at speeds above a few gigahertz. While optical interconnects are expected to relieve this bottleneck, the 90° out-of-plane turn required for card-to-backplane connections typically relies on 45° micromirrors that add bulk and degrade reliability. A more cost-effective option that eliminates the use of micromirrors is a flexible array-waveguide evanescent coupler (AWEC; see figure) that has been demonstrated by researchers at New Span Opto-Technology and the University of Miami (both in Miami, FL).1

The AWEC relies on waveguide directional coupling between the backplane waveguide and a flexible waveguide connected to the card. The exposed-core evanescent-wave coupling results in a periodic energy exchange between the parallel-channel optical waveguides, with propagating waves behaving according to known energy-transfer formulae based on the coupling propagation length, the coupling materials, and the waveguide separation.

To demonstrate the AWEC technique, a 12-channel waveguide array coupler was designed to interface with a 12-source vertical-cavity surface-emitting laser (VCSEL) array. Each waveguide in the 12-channel multimode ribbon had dimensions of 35 × 35 µm with a pitch (separation between the centers of adjacent waveguides) of 250 µm. The core of each waveguide was exposed for evanescent coupling; the AWEC ribbons were fabricated from GuideLink polymer material provided by Optical CrossLinks (Kennett Square, PA).

Because proper alignment is needed to improve evanescent coupling efficiency, simple coupling hardware was fabricated-a square enclosure with screws-to align and apply pressure to the ribbons. By plotting coupling efficiency as a function of coupling length, the researchers observed a 6.7 mm coupling-length period and coupling improved to a saturation value as the pressure from the coupling hardware was increased. The use of multimode waveguides with larger width dimensions allows a larger misalignment tolerance between the two AWEC ribbons: lateral misalignments of ±10 µm can preserve coupling efficiency change within 15%.

Multimode connectors have limited modal dispersion over short connection distances, and are therefore suitable for high interconnection speeds. Using commercially available 2.5-GHz-per-channel array transmitter-receiver modules from Picolight (Louisville, CO), the AWEC ribbons were connectorized with standard ribbon connectors and data transmission was analyzed. Evanescent optical interconnection and data transmission was successful for speeds of 2.5 GHz for each channel of the AWEC connector. Because optical attenuation is a material property and virtually independent of frequency, the AWEC ribbon connector should be able to perform at speeds much higher than 2.5 GHz. In fact, recent testing has demonstrated 10 GHz interconnect performance.

New Span Opto-Technology is seeking to jointly develop or license this patented technology with a computing or test-and-measurement company. “Because the optical ribbon is compatible with existing technologies and can be packaged using conventional circuit-board fabrication techniques, we expect it to receive widespread use in the next one to two years,” researcher Michael Renxun Wang says. “The technology should also benefit military applications in fast target identification and missile-interception computing, and commercial applications, including data communications, data fusion, neural networks, and high-speed pattern recognition.”

REFERENCE

1. J.J. Yang et al., Optics Letters 32(1) 14 (January 1, 2007).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.