Diatoms may be new source of electronic and photonic structures

Using a chemical process that converts silica in the shells produced by microscopic ocean creatures into silicon, researchers at the Georgia Institute of Technology (Georgia Tech; Atlanta, GA) have fabricated innovative gas sensors with “a combination of speed, sensitivity, and low voltage operation that exceeded conventional sensors,” said Kenneth H. Sandhage, a professor in the School of Materials Science and Engineering at Georgia Tech. “The unique diatom-derived shape, high surface area and nanoporous, nanocrystalline silicon material all contributed towards such attractive gas sensing characteristics.”

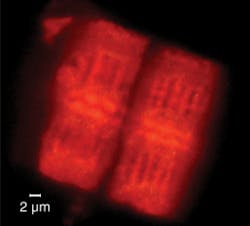

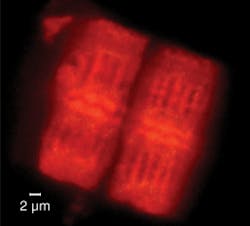

The researchers also noted that photoluminescence of the nanoporous silicon in ultraviolet light, which may lead to photonic applications, was enhanced by partial oxidation in water as shown in this image. Silicon is normally produced from silica at temperatures well above the silicon melting point (1,414ºC), so solid silicon replicas cannot be directly produced from silica structures. The researchers used a chemical-conversion process at only 650ºC, which allowed preservation of the complex channels and hollow cylindrical shape of the diatom. Contact Kenneth Sandhage at [email protected]. (Image courtesy of Georgia Tech)