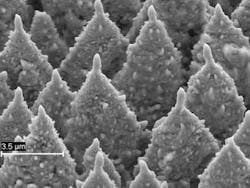

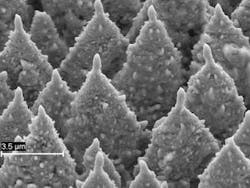

Nanospikes add new functionality

By creating “nanospikes”-nano- and microsize hills and valleys-on the surface of metals and semiconductors, researchers at the University of Virginia (Charlottesville, VA) expect that the increased surface-area of the materials could, for example, increase the absorption of light for optoelectronic sensor and solar-energy applications, improve cell growth and integration of metal-coated hip or joint implants, or dissipate heat more efficiently in computer chips.

Initial nanospike experiments used undoped germanium wafers exposed to 130 fs, 1.4 mJ pulses at 800 nm with a repetition rate of 1 kHz from a regeneratively amplified Ti:sapphire laser system. Very sharp conical microstructures with nanospikes atop are formed when the sample is scanned under the laser beam (fluence approximately 0.6 J/cm2). The resulting microstructures are 10 to 15 µm tall, with a base diameter around 5 μm tapering down to approximately 100 nm near the tip, and are formed spontaneously in a self-assembled manner inside the laser spot. The spike formation is dependent on laser fluence and number of shots. In addition to nanospikes in germanium and other semiconductors, the team has successfully textured metals like titanium and stainless steel. Contact Mool Gupta at [email protected].