When focused, an ultrafast pulsed laser beam becomes a pen capable of writing microstructures within glass. The structures arise when the glass at the beam focus melts, forms color centers, or breaks down in some other way. Different processes allow the construction of various microstructures: for example, a change in refractive index can result in a waveguide. Researchers at the Chinese Academy of Sciences (Shanghai, China), Ritsumeikan University (Shiga, Japan), the Japan Science and Technology Corp., and Kyoto University (both of Kyoto, Japan) are now creating structures in glass by optically manipulating the valence state of transition metal ions in doped glass, changing the material's absorption of light.1

Using clear glass doped with manganese (Mn) and iron (Fe) as the blank slate, the researchers focus a beam of pulses from a regeneratively amplified Ti:sapphire laser into the material with a microscope objective lens. The laser emits 800-nm, 120-fs pulses at 1 kHz, producing an average power of 400 mW. The 10X lens produces a spot size of 10 µm. When aimed at one location for 16 pulses, the focused beam forms an area of damaged glass 4 µm in cross section surrounded by a 30-µm purple halo. The purple region extends along the optical axis to a length of 1.5 mm. The purple color is a result of Mn2+ ions being photo-oxidized to Mn3+, which increases the absorbance in the 300- to 1000-nm wavelength region. The change in valence state is long-lived; at room temperature, no change in absorption from the induced Mn3+ ions was seen even after one month.

Because Mn and Fe doped glass has no absorption in the 800-nm region, the photo-oxidation is a nonlinear optical process, with multiphoton absorption one of the likely processes. The length of the purple region is far greater than the 200-µm Rayleigh length of the focused beam, causing the researchers to posit that a nonlinear change in refractive index induced by the high (1012 W/cm2) optical-power density causes self-focusing of the beam. In addition, a nonlinearly created white-light supercontinuum probably plays a part in the formation of the microstructures. The length of an induced microstructure was directly proportional to the square root of the average power of the laser beam, agreeing well with theories of self-focusing and filamentation.

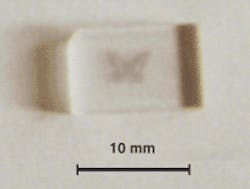

Extended structures can be fabricated by writing with a moving spot (see figure). The femtosecond writing technique might be used in micro-optical devices such as three-dimensional optical memory, waveguide magneto-optical switches, and photonic crystals, says Jianrong Qiu, one of the researchers.

REFERENCE

- J. Qiu et al., Appl. Phys. Lett. (Nov. 26, 2001).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.