Changing times require changing tests

JOHN PERLICK

Instrumentation used to measure and analyze signal integrity, such as oscilloscopes, bit-error-rate testers (BERTs), network analyzers, and spectrum analyzers, provides only piecemeal noise snapshots of different components in an optical networking system, making it challenging to cross-correlate error information. To obtain a more comprehensive view of signal integrity, modular time-interval analyzers (TIAs) can cross boundaries between frequency, protocol, data rate, and even electrical/optical domains. Users can apply such a "protocol-agnostic" testing architecture with end-to-end calibration in the lab as well as on the production floor.

It seems that every data path in every system, both optical and electrical, is facing potential migration to high-speed serial. The transition from SONET-based networks to heterogeneous telecom/datacom networks has resulted in a proliferation of data communications standards. Some standards are being addressed in applications such as Gigabit Ethernet, Fibre Channel, InfiniBand, Optical Interface Forum, SONET, and passive optical networks for fiber-to-the-home. As these new systems attempt to deliver more payload, designers and manufacturers need dependable component testing to guarantee interoperability and reliable bit-error-rate performance across a range of operating conditions.

Along with the increasing diversity of protocols and applications, designers also face the expected rise in volume of existing optical-network hardware. Signal integrity becomes critically important and difficult to achieve with data rates climbing to multigigabit levels and wavelength-division multiplexing expanding the number of individual channels carried on each fiber. As optical technologies move outward from the network core, the number of interfaces multiplies exponentially and requires higher volumes of rigorously tested components.

Increasing complexity of interface designs also changes the testing process. To meet higher bandwidth requirements on the optical side, transceiver designs must multiplex/demultiplex parallel data streams from several lower-speed lines on the electrical side. Handling heterogeneous data formats and denser signal packing over longer distances requires tight integration of complex circuitry on the same chip with the opto/electrical interfaces. Test instruments must comprehensively address the whole interface as a unified entity and then flawlessly identify and analyze specific problem areas in either the electrical or the optical domain.

Fundamental shift

Driven to reduce test times while ensuring robust signal analysis, the industry is responding with a fundamental shift in test methodologies. Historically, oscilloscopes and BERTs have been the mainstays for interface testing, but neither of these approaches can deliver fast and comprehensive signal analysis for production testing of complex high-speed interfaces.

An oscilloscope, for example, provides a qualitative view, slowly creating eye diagrams that visually depict how high-frequency noise components are interacting with one another. The BERT counts bit errors over time to extrapolate the likelihood of future bit errors. Scopes and BERTs present only one view of the noise, which may or may not be conclusive. As production volumes increase, the time required to obtain adequate test data using oscilloscopes and BERTs makes them impractical for conducting production-floor quality assurance.

While dedicated test platforms for specific scenarios are viable, modular platforms with the flexibility to adapt to multiple scenarios are more practical. Not only does the modular approach tailor the modules for individual testing requirements, it also maximizes return on capital investments by future-proofing the system against obsolescence.

Modular approach

Central to a modular test methodology is the use of TIAs, which can directly measure and identify the contributors to eye closure (see Fig. 1). The TIA deconvolves jitter into its deterministic and random components to conduct compliance testing required by modern communications standards. Total jitter (TJ) is the convolution of all independent jitter component-probability density functions. Total jitter is comprised of random jitter (RJ), which has unbounded Gaussian characteristics, and deterministic jitter (DJ), which can be segmented into periodic jitter (PJ) and data-dependent jitter. Data-dependent jitter is further segmented into jitter that is caused by duty-cycle distortion (DCD) or intersymbol interference (ISI).1

By comprehensively addressing all of the components of jitter, a TIA can quickly assess the performance of an optical or electrical interface and then independently analyze various jitter components to reveal specific problems affecting the BER. Periodic jitter could point to interference from a clock signal or electromagnetic interference from a power supply or other component. Data-dependent jitter could indicate bandwidth-limiting or dispersive effects in the signal path. The presence of excess RJ might signal high thermal noise in electrical elements or noise from the laser source.

Though oscilloscopes and BERTs are useful within narrow parameters, neither can offer the broad set of tools available in a modern multichannel TIA, which can analyze how a waveform fundamentally changes over time and can convolve these measured data to estimate BER. Since a TIA can make these measurements regardless of data standard, bit rate, or signal source, the fundamental hardware measurements of time-interval analysis provide maximum extensibility to the user. An optical-transceiver manufacturer can use a single piece of test equipment to ensure device performance across a product portfolio of components designed for various data-communications standards and data-rate applications in both the electrical and optical domains. Multichannel TIAs can simultaneously test several communication signals and provide a measure of jitter crosstalk and wander skew in parallel optical networks.

Standards compliance

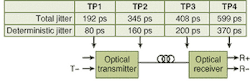

Most current serial data standards specify maximum TJ and RJ values as measured at specific test compliance points (see Fig. 2). The maximum TJ and DJ defined in the IEEE 802.3 specification for 1000BASE-SX and 1000BASE-LX have four compliance test points: TP1, the electrical input to a fiberoptic transmitter; TP2, the optical output of the transmitter; TP3, the optical input of a fiber optic receiver; and TP4, the receiver's electrical output. To provide consistent ratios of jitter to data, the corresponding specifications for 10 Gigabit Ethernet will require one-tenth as much TJ and DJ at each compliance point.A measurement of the optical signal at TP2 indicates acceptable TJ but the DJ is too high. The good news is that the RJ is therefore quite low, but because the DJ exceeds specifications, the transceiver is not in compliance (an oscilloscope might not even catch such a problem). Using a TIA, we can further investigate the excessive DJ in the frequency domain to analyze the frequency and magnitude of the PJ. In the first scenario, the TIA reveals that the power spectral density of the jitter has a peak at 400 MHz. Because this corresponds with an adjacent circuit's clock frequency, it immediately indicates a possible crosstalk problem between the GBIC circuitry and the clock circuit. Such a targeted analysis would be difficult using a BERT to take multiple readings at various frequencies.

In another scenario, the DCD or ISI analysis tools indicate that the excess DJ displays a pattern of data-dependent jitter. Further investigation might indicate that the serialization/deserialization device does not provide equal high- and low-bit periods (DCD) or that the edge location is dependent on the last bit value (ISI). An ISI fault could result from printed circuit-board design flaws such as excessive circuit line length or a transmission line mismatch. Again, measurement and characterization of these subelements of DJ with a single BERT or oscilloscope is impractical, thus making it difficult to hone in on the underlying problems without using a modular TIA.

The acquisition of specific raw jitter data is useful merely as an indicator of compliance or noncompliance. In the case of 1000BASE-SX, a measurement at compliance point TP2 exceeding 345 ps of TJ or 160 ps of DJ only tells the designer that the transceiver has a problem; it does not provide any specific clues as to what is causing the fault condition. By enabling the designer to simultaneously acquire data from all test points and to graphically see the relative levels and frequency patterns for all jitter elements, modular multichannel TIA systems support comprehensive real-time analysis that can drill down to help identify the root cause of problems as well as assess compliance.

REFERENCE

1. See http://www.wavecrest.com/technical/jitterfund.htm.

John Perlick is director of marketing of the optical division of Wavecrest, 7626 Golden Triangle Dr., Eden Prairie, MN 55344; e-mail: [email protected].