PLASMONICS: Surface plasmons switched at terahertz rates

The field of so-called active plasmonics has seen an unprecedented leap in switching times, thanks to the favorable properties of aluminum and the efforts of a number of researchers at the University of Southampton (Southampton, England) in collaboration with an academic at Georgia State University (Atlanta, GA).

As evidenced by its nickname of “light on a wire,” plasmonics has long promised to deliver on all the advantages of light propagation for data transmission combined with the more-convenient physical characteristics of standard micro- and nanoelectronics. But to oust standard lithographically produced electronics for next-generation computing, light on a wire will need to be switched at ultrafast timescales.

Efforts to effect such switching have been ongoing in recent years, making use of a wide range of media including thermoelectric and electro-optic materials, quantum dots, and photochromic molecules. However, switching the packets of electron oscillations has so far been limited to submillisecond timescales, reaching down into the nanosecond regime in 2007.1

Now, Southampton’s Kevin MacDonald and his colleagues have demonstrated a jump some five orders of magnitude over the prior best efforts, modulating plasmon pulses in a metal-dielectric waveguide at the 100-femtosecond level–a modulation bandwidth in the terahertz range.

The work is the outcome of a long history of plasmonics research in the group, who coined the term “active plasmonics” in a 2004 paper outlining the transient switching of surface-plasmon-polariton (SPP) signals, which relied on a gallium thin film as the switching layer.2

Further work with a prism switching geometry led to a simpler idea, MacDonald says. “We then considered that a defined section of dedicated switching material might not be needed at all–we could perhaps, on the femtosecond timescale, rely on the nonlinearity of the metal component of the waveguide.”

Optical excitation

By direct optical excitation of the metal in silica-aluminum waveguides, the team has now accomplished that feat, as they reported at the NanoMeta 2009 conference (Jan. 5 to 8; Tirol, Austria).

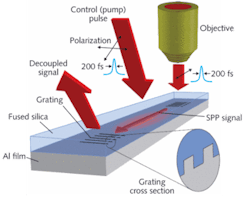

They started with waveguides made by evaporating aluminum onto a fused-silica substrate with gratings formed by ion etching. Coupling and decoupling gratings were formed of 40 lines at a period of 0.522 and 1.184 µm, respectively.

An optical pump/SPP probe setup used a Ti:sapphire source producing 200 fs pulses centered at 780 nm, both to launch the SPP and to serve as the pump pulse to directly optically excite the aluminum (see figure).

The result? The researchers saw a switching modulation of 7.5% of the plasmon wave’s intensity, using an input fluence of just 10 mJ/cm2–comparable to that needed to write a bit on a CD.3

The nonlinearity and attendant switching speed of the technique occurs, the researchers say, because the optical excitation is near the interband transition in aluminum. The transient response includes a fast component with a relaxation time shorter than the pump-pulse duration, with a slow component with a relaxation time around 60 ps.

Straightforward manufacturing

The approach is attractive not only because of its unprecedented speed and simplicity: manufacturing would be compatible with existing CMOS infrastructure, and the lack of any organic components would make for more-robust devices.

“Our result represents a significant advance in the achievable modulation bandwidth for active plasmonics,” says MacDonald, though he admits that the demonstration is more at the “proof-of-principle” stage than toward immediate practical applications.

In fact, the advance may be too dramatic for its own good. “Some would argue that femtosecond switching is actually too fast for the envisioned next-generation applications of plasmonics in data transport and processing,” he says.

Henry van Driel at the University of Toronto has also worked toward ultrafast control of SPPs, employing instead gold gratings–and is impressed with the new work.4 “While the amplitude control is modest, the authors do demonstrate control of plasmons on a timescale appropriate for rapid information processing,” he says.

“There is the usual tradeoff between amplitude and time of response,” he adds. “No doubt, future developments will try to employ various hybrid schemes, consisting of various combinations of fast and slow nonlinearities, to achieve optimal performance for a given functionality.”

MacDonald says that his group is working to understand more about the effect–such as the group velocity dispersion and optical loss that plague many plasmonics efforts–before working further toward applications.

“We anticipate that the observed effect should depend quite strongly on wavelength around the interband transition of aluminum. We are also analyzing the possibility of nonlinear propagation modes like solitons, pulse compression, and self-focusing, based on the nonlinearity of the metal waveguide component.”

REFERENCES

- Pacifici et al., Nature Photonics 1, p. 402 (2007).

- Krasavin et al., Appl. Phys. Lett. 84, p. 1416 (2004).

- MacDonald et al., Nature Photonics, DOI: 10.1038/nphoton.2008.249.

- Rotenberg et al., Opt. Lett. 33, p.2137 (2008).