Thin-film III-V lasers bonded to silicon have low threshold-current densities

In a step that brings practical on-chip optical interconnects closer to reality, researchers at Duke University (Durham, NC) and the University of Wisconsin-Madison have developed an improved thin-film III-V edge-emitting laser bonded to silicon (Si). The enhancements consist of the simultaneous inclusion of metal contacts on both sides of the thin film structure (which helps lower the threshold current density), metal/metal bonding on the bottom of the laser (to dissipate heat), and flexibility in the metal-contact geometry, which allows the laser to be optimized for either high power or single-mode operation.

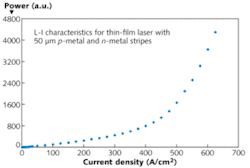

The thin-film layers in the single-quantum-well separate-confinement-heterostructure laser were various combinations of aluminum, gallium, indium, and arsenic (some doped with Si or zinc). Two types were created: a gain-guided version with a bottom p-stripe and a top n-stripe; and an index-guided version with a bottom p-ridge and a top n-stripe. Both lased at a 995 nm wavelength. The injected threshold-current density for the first type was 420 A/cm2, and for the second was 244 A/cm2—among the lowest ever reported for these sorts of lasers, say the researchers. Contact Sabarni Palit at [email protected].