Nanograined Y2O3 ceramic transmits as well as single crystal

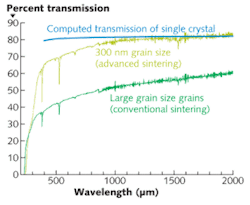

Certain sesquioxides, such as yttrium sequioxide (Y2O3), would make excellent high-power laser hosts but for one drawback: their melting point is so high that single laser crystals cannot be grown. For this reason, many research groups are trying to create transparent sequioxide ceramics (which consist of many small crystals) to use instead; however, the groups’ sintering approaches tend to result in ceramics with coarse grains tens to hundreds of micrometers in size, reducing the transparency and making the ceramics more susceptible to heat absorption. When small grains are achieved, the ceramic tends to be porous, again reducing transmission.

Scientists at Clemson University (Anderson, SC) have succeeded in creating a Y2O3 ceramic that is both dense and nanograined. The material was synthesized by a two-stage, pressure-assisted sintering process. Samples were heated at 10°C/min to 1500°C to a 98% density, then fired at 1400°C for 20 h, with final grain sizes reaching 316 ±32 nm. Afterward the samples were hot isostatically pressed at 1300°C and 206 MPa for 3 h, making them fully dense. After polishing, the ceramic had a transmittance above a 1200 nm wavelength that was equivalent to that of a single crystal of Y2O3. Contact John Ballato at [email protected].