1.3-kW fiber laser can be further scaled

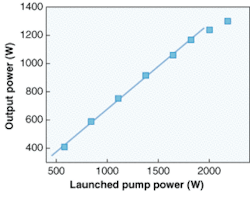

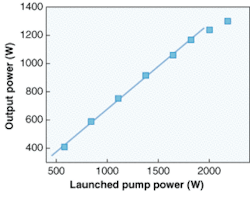

Fiber lasers have become serious competitors to other high-power lasers. Their favorable surface-to-core-volume ratio provides efficient heat removal, allowing pump power to be increased with little loss in beam quality. About a year ago, a group at the Friedrich-Schiller University, in cooperation with the Institut für Physikalische Hochtechnologie (both in Jena, Germany) achieved a 500-W output with a large-mode-area fiber co-doped with ytterbium and neodymium (see Laser Focus World, August 2003, p. 40). Now, researchers from CeramOptec (Bonn, Germany), cooperating with the same Institut für Physikalische Hochtechnologie, has reached an output of 1.3 kW with an overall slope efficiency of 60% (see Fig. 1).1

The researchers used a similar fiber co-doped with Nd and Yb ions; however, they pumped only the Yb transitions using diode-laser modules emitting at 940 and 976 nm. The photon energies at these wavelengths are closer to that of the laser emission in the spectral range of 1080 to 1110 nm (as compared to Nd pumping at 808 nm), so that the quantum yields are higher, resulting in a further rise in average slope efficiency, reducing thermal loading.

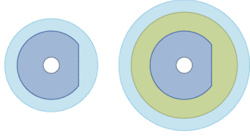

Even more important, the researchers developed a novel multiclad fiber design that has the previous D-shaped inner cladding (the so-called pump core) made of silicon dioxide (SiO2) for pumping but, in addition, a fluorine (F)-doped SiO2 cladding for guiding the pump radiation, and a third outer cladding made of polymer primarily for mechanical stabilization and support of the waveguiding (see Fig. 2). The F:SiO2 cladding guiding the pump radiation enabled a considerable increase in pump power. Multiclad fibers show significant advantages in terms of laser performance: in comparison with standard double-clad fibers, the output power increases by 20% and the slope efficiency by 15%, while the operating temperature (which rises in proportion to thermal loading) decreases significantly.

The researchers saw excellent stability in the laser output, no self-pulsing, and no fiber degradation during the experiments. Thus, further power scaling seems possible, making fiber lasers highly interesting candidates for materials processing and many other applications. The work was funded by the German Ministry of Education and Research.

REFERENCE

- T. Sandrock et al., Solid State Diode Laser Tech. Rev. 2004, Tech. Digest (Directed Energy Professional Society, 2004), poster P-27.