Laser peening enters commercial mainstream

A laser-peening technique based on the Nd:glass slab technology developed for the National Ignition Facility (NIF) at Lawrence Livermore National Laboratory (LLNL; Livermore, CA) has completed the transition from the laboratory into full commercial production and is beginning to find new applications. Originally conceived in the late 1960s, laser peening can extend the life of metallic components by about an order of magnitude (10 to 12 years for a jet turbine blade as opposed to one year, for example). Actual commercial use has been limited until a few years ago, however, when lasers with high enough powers and pulse rates became available—such as the Nd:glass system based on NIF technology that can continuously deliver energies of up to 120 J per pulse at repetition rates as high as 10 Hz (see Laser Focus World, February 1998, p. 40).

About 7000 jet-engine turbine blades have been peened using Nd:glass systems since the spring of 2002, when the Metal Improvement Company (MIC) subsidiary of Curtiss-Wright (Paramus, NJ) began to offer laser peening through an exclusive license with LLNL, in addition to its traditional metal-shot-peening services. The peening process strengthens metal by applying compressive stress, which penetrates about four times deeper into a material when applied using a laser than with metal shot. The laser also leaves a smoother surface, while allowing for more precise targeting of the compressive force and improved heat resistance in the finished material.

Square beam

The actual laser-peening process imparts energy densities on the order of 50 to 250 J/cm2 to a metal surface through laser-impact spot sizes ranging from 3 to 20 mm2, with pulse durations on the order of 10 to 30 ns. Optics developed at MIC deliver a square beam with a flat profile (10% root-mean-square nonuniformity) across about a 1-m distance to the image plane at a spot size, duration, and energy density desired for a specific material and treatment objective—somewhat similar to a lithographic process.

Peening an aluminum alloy might only require a laser fluence of 60 J/cm2, while high-strength steel might require 200 J/cm2, according to Brent Dane, who originally developed the laser system while working at LLNL. Dane now directs laser technology at MIC, which continues to develop related processes in an ongoing cooperative research and development agreement with LLNL. He added that the square beam shape provides much more efficient surface coverage than a round beam, and that the flat beam profile allows the same compressive stress to be delivered using about a third the power that would be required using a Gaussian beam.

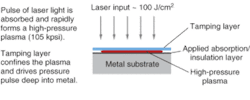

Each laser pulse imparts a 106-PSI pressure pulse at the component surface by generating a plasma in a thin layer of protective tape or paint on the metal surface. The plasma is spatially contained from spreading across the surface area by a 1- to 3-mm-thick layer of "tamping" water and thus transmits a shock wave directly forward into the metal (see figure).

A complete laser-peening system, including robotics for positioning materials during treatment and computer-control systems, costs about $2 million—four to eight times as much as metal-shot-peening systems. And MIC, which does not sell systems but provides peening services, has installed two in a Livermore, CA, location for preventive maintenance on turbine blades already in use. Two more laser-peening systems established in the summer of 2003 at an MIC location in Earby, England, treat newly manufactured turbine blades prior to installation in aircraft. Early this year, the company plans to add beam-scanning technology that will allow laser peening of components that are too large to be handled by robots. By the end of this year, MIC plans to roll out a transportable laser-peening system that can be taken to an air facility to treat aircraft without disassembly.

The tighter process control available with laser peening is also extending potential applications into areas—such as metal shaping of titanium airfoils in high-performance aircraft—that would exceed the capabilities of metal-shot peening. Applications currently being developed other than military and aviation include treatment and forming of components used in health-care delivery, nuclear-power generation, and drilling for petroleum products.