Subwavelength low-loss silica wires guide light

While ordinary optical fiber confines light almost entirely within its core, a type of silica fiber created by researchers at Harvard University (Cambridge, MA), Zhejiang University (Hangzhou, China), and Tohoku University (Sendai, Japan) has a diameter so small that much of the light it guides is transmitted outside the fiber.1 Versions of the low-loss "nanowire" have been fabricated by the researchers in diameters ranging from 50 to 1100 nm; about half the light transmitted by a 300-nm diameter exists outside the fiber in the form of evanescent waves, while the smallest-diameter light-transmitting fiber (180-nm diameter, guiding 633-nm light) made by the group carries up to 90% of its optical power in evanescent waves, according to Eric Mazur of Harvard, the group's leader. The fiber may one day be made into chemical sensors and other photonic devices.

Ordinary optical fiber has a core larger in diameter than the wavelength of the light passing through it—which, for typical wavelengths, means a diameter of at least a couple of microns. Similar core diameters have been achieved in "holey" fibers, in which a lacy microstructure supports a core in air; the large difference in refractive index between the core and the surrounding air allows for tight containment and nonlinear effects such as supercontinuum generation (see Laser Focus World, July 1999, p. 17).

To achieve the much smaller 100-nm-scale cores, the large index difference of an air cladding is necessary to adequately guide light—which in practice means fabricating bare (unclad and nonmicrostructured) fibers. But drawing silica wires of such small diameters has, in the past, resulted in fibers too rough and uneven to guide light.

The researchers developed a fabrication process that evens the temperature distribution of a silica wire as it is being drawn so that the wire ends up with smooth walls. First, a silica wire with a diameter in the micron range is placed against a tapered sapphire-fiber tip that has a diameter at its end of about 80 µm. The taper-and-wire assemblage is brought into a 6-mm-diameter flame, which heats the wire to just above the 2000 K drawing temperature. The sapphire taper is rotated to wind the wire into a coil, then the taper and coil are moved away from the flame. At this point, the wire is drawn at a speed of 1 to 10 mm/s, with the sapphire acting to even the temperature. Wire lengths of up to tens of millimeters have been drawn. The 180-nm diameter light-transmitting nanowire has been fabricated in several-millimeter lengths, says Mazur.

Micron-scale bending radii

The wires can be bent to tiny radii—a 280-nm-diameter wire is bendable to a radius of 2.7 µm, indicating a tensile strength of greater than 4.5 GPa. Allowing plastic (permanent) deformation while bending has resulted in radii of less than a micron. Light can be transmitted through 5.6-µm-radius bends with low loss.

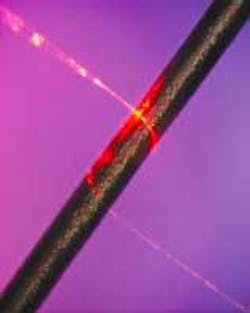

Because much of the light is in the form of evanescent waves, bringing one silica nanowire up to another allows coupling of light between them. In one example, a 520-nm-diameter wire tied in a simple knot forms a ring microcavity with a 15-µm diameter; preliminary measurements show a cavity Q factor of about 1500 for light of a 1550-nm wavelength.

While ordinary optical fiber appears to the naked eye as a uniform glowing line, the wires created by Mazurís group have a beaded appearance when viewed under magnification because any contamination along the nanowires' surface can scatter the light beam. The researchers say this sensitivity to surface contaminants could lead to use of the nanowires as molecular sensors. "You could fit the surface of the wire with receptors for biological or chemical molecules," says Mazur. "If those target molecules are present, they'll attach to the receptors and you'll see a strand of tiny lights shining when you launch light into the wires."

The strength and smoothness of the wires make them candidates for use in microphotonic devices. Their nanometer scale allows new assembly approaches: to couple one wire to another, the Harvard researchers merely bring the two wires next to each other—van der Waals forces take over to hold the wires together.

REFERENCE

- L. Tong et al., Nature 426, 18 (Dec. 2003).