Newsbreaks

Continuous-wave single-fiber laser tops 1-kW output

A single-fiber laser with an optical output of greater than a kilowatt has been demonstrated for the first time by researchers at the University of Southampton's Optoelectronics Research Centre (Southampton, England). The 8-m-long continuous-wave ytterbium-doped laser emits 1.01 kW at a 1.09-µm wavelength and an 80% slope efficiency. To achieve such high output without damage, the researchers used a large core diameter of 43 µm and a numerical aperture (NA) of 0.09.

The fiber is double-clad, with a D-shaped inner cladding of 650/600-µm size that enables efficient coupling of the pump light. The outer cladding is polymer, with an inner-cladding NA of 0.48. The pump sources are two diode stacks emitting at 972 and 975 nm respectively, with one stack pumping each end of the fiber. The fiber ends are held in temperature-controlled V-grooves to prevent thermal damage. Laser beam quality M2 is 3.4; because the laser operates relatively far from its damage threshold, its M2 could be improved by reducing the core diameter or NA, or by introducing mode-selecting techniques such as a fiber taper or bend-loss filtering. Contact Yoonchan Jeong at [email protected].

Confocal microscope scrutinizes diamond microlens arrays

Just as diamonds are rare in nature, optical elements made of single-crystal diamond are rare in the optical world. Although diamond's durability, high (in fact, unmatched) hardness and thermal conductivity, high index of refraction, lack of birefringence, and large spectral-transmission window would make the material a gem in the optical designer's toolkit, diamond's high cost and difficulty to shape has for the most part relegated its use to the occasional small window or other element for harsh environments.

Now, scientists at the University of Strathclyde (Glasgow, Scotland) are fabricating microlens arrays from Type-IIa natural single-crystal diamond (type IIa has the highest thermal conductivity). Using photoresist reflow and inductively coupled plasma etching arrays with 18-µm-diameter, 1.5-µm-high lenses on an approximately 25-µm pitch were fabricated with a root-mean-square surface roughness of 1.2 nm. The researchers used a laser scanning reflection/transmission confocal microscope to measure focal length (21 µm), spot size (1.4 µm), and surface profile of the microlenses, providing 3-D images of the optical field to high resolution. The microlens arrays could be integrated with gallium nitride–based photonic devices.

Contact Erdan Gu at [email protected].

Quantum-cryptographic transmission rate reaches 1 Mbit/s

Researchers at the National Institute of Standards and Technology (NIST; Gaithersburg, MD) have demonstrated the fastest-yet quantum-cryptographic transmission, besting previously reported results by two orders of magnitude. In their system, a 1550-nm classical channel operates in parallel with an 845-nm quantum channel, transmitting at up to 1.0 Mbit/s. Clock-recovery information arises from the classical channel at 1.25 Gbit/s; in other words, the NIST scientists time-stamp the quantum-key-distribution photons, then look for them only when they are expected to arrive.

The data-handling electronics are packaged in a pair of programmable printed-circuit boards that plug into standard personal computers. Photon losses caused by imperfections in the photon sources and detectors, optics, and procedures reduce the key generation rate; however, the high transmission rate makes quantum-key distribution practical for a variety of new applications, such as large network distributions or streaming encrypted video. Improvements in the resolution of single-photon detectors could yield another order of magnitude increase in transmission rate without increasing the error rate. Here, physicist Joshua Bienfang sets up the quantum-key-distribution system (an 8-in. collecting telescope is at left) to receive a string of photons from colleagues stationed on the top floor of the building in the background. Contact Joshua Bienfang at [email protected].

Maskless lithographic system scans rather than steps

Maskless photolithography, in which the conventional photomask is replaced by optoelectronic hardware that modulates a line or patch of light, is not a new concept. It has not found practical use, however, mainly because of its very low throughput. In one standard concept, the projected pattern from a 2-D spatial light modulator (SLM) is stepped across a substrate; however, the low pixel count of even large SLMs slows the process way down.

Researchers at Anvik (Hawthorne, NY) are speeding things up by using scanning rather than stepping (just as leading-edge lithographic exposure equipment has switched from stepping to scanning). A liquid-crystal SLM is illuminated by a hexagonal beam from a pulsed frequency-doubled Ti:sapphire laser emitting at 436 nm. During scanning, the pixel pattern on the SLM moves backward along the SLM to match the scanning speed; in adjacent scans, the pointed hexagon sides overlap to create a uniform illuminated dose over a field much larger than individual scans. In an initial test, of a small-image-field (0.3 mm) projected pattern, a 25 × 25-mm image area was exposed with good imaging of 1.5-µm features. A second maskless system, under construction, will pattern a similar-sized area in 45 seconds. Contact Kanti Jain at [email protected].

Paper Blu-ray DVD is recyclable

At the Optical Data Storage topical meeting in Monterey, CA, in April, researchers from Sony and Toppan Printing (both in Tokyo, Japan) described their recent development of a 25-Gbyte ROM DVD disc fabricated on a paper substrate and formatted in accordance with the emerging Blu-ray Disc standard for high-definition (HD) DVD optical storage (see related story, p. 31). The Blu-ray Disc format calls for a 1.1-mm-thick substrate and a 0.1-mm-thick light-sensitive cover layer.

The disc substrate consists of a 0.6-mm-thick paper layer with a 0.18-mm-thick polycarbonate cover layer bonded to top and bottom using a pressure-sensitive adhesive, a 0.1-mm-thick light-sensitive cover layer at the top, and a 0.1-mm-thick UV-cured film at the bottom. The composition of the disc exceeds the 51%-paper minimum for recycling in Japan; the resulting optical-storage device yields jitter values less than 7%, confirming the feasibility of fabricating a recyclable Blu-ray Disc. Contact Takeshi Yamasaki at [email protected].

Single-mode white-light supercontinuum source is compact

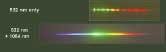

Researchers at the Institut de Recherche en Communications Optiques et Microondes (Limoges, France) have generated a smooth and truly single-mode white-light supercontinuum in normally dispersive holey optical fiber. The result was achieved by suppressing the cascaded Raman effect, which as a rule occurs in normally dispersive fiber. A dual-wavelength pumping scheme allows simultaneous excitation of the fiber in its anomalous and normal dispersion regions at 1064 and 532 nm by the fundamental and second-harmonic signals of a passively Q-switched Nd:YAG microchip laser. The presence of the second IR pump signal suppresses the visible-pump-signal-induced cascaded Raman effect to yield the smooth visible continuum.

The white-light source covers the entire visible from the near-UV (350 nm) to the near-IR (720 nm) without any discontinuity and delivers up to 10 mW. Scalability to a 1-W output level is under way. The transverse-mode profile is single-mode from the blue to the red. The dual-wavelength pumping scheme permits the use of a low-peak-power pump source as compared to commonly used bulky solid-state femtosecond lasers. The source will be implemented in biophotonics devices. Contact Pierre-Alain Champert at [email protected].

Quantum-well-intermixing fabrication produces high OEIC yield

If optoelectronic integrated-circuit (OEIC) chips could be made at as high a yield as electronic chips, then progress might be accelerated in major markets such as ultra-high-bandwidth communications networks for enterprises and homes. In this vein, engineers at Intense Photonics (Glasgow, Scotland) have fabricated chips that integrate up to 100 or more multifunction optical components on a single die. The success stemmed from a quantum-well-intermixing process developed at Intense.

In the process, all component elements are fabricated in a single stage on a chip, unlike regrowth-based compound-semiconductor processes. Thus, system architectures can be based on highly integrated optical components such as laser-and-modulator combinations. The chip shown is an individually addressable gallium arsenide laser array operating at 980 nm and 220 mW of power per laser. Two passive-waveguide components are integrated on either side of each laser element, providing serial integration in each channel, raising yield by raising the threshold for catastrophic optical damage, and relaxing mechanical cleaving and packaging alignment tolerances. Such an array could be used to lower the costs of building fiber-amplifier pumps; alternatively, the bandgaps of each laser could be adjusted to make arrays for WDM applications. Contact John Marsh at [email protected].

Light-emitting plasma rotates via circularly polarized microwaves

The electrode-less sulfur lamp is a white-light source that contains a microwave-generated sulfur plasma. Extremely efficient (170 lm/W) and long lasting, the bulb was developed in the 1990s and was accompanied by enough fanfare to make its subsequent descent into near-anonymity (and relegation to Internet chat rooms) all that much more a curiosity. In fact, the bulb has some shortcomings—one of them being that to keep the bulb from being perforated by hot spots in the glowing but stationary plasma blob, the bulb itself must be continuously mechanically rotated.

Researchers at Sejong University (Seoul, Korea), the Korea Basic Science Institute, and the Korea Advanced Institute of Science and Technology (both of Daejon, Korea) have experimentally demonstrated a way around this problem—the formation of plasma discharges that, because they are excited with circularly polarized microwaves and absorb the radiation's angular momentum, rotate inside the bulb at frequencies ranging from 0.1 to 20 Hz. The 2.45-GHz microwave radiation had a power of up to 1.2 kW with no external magnetic field. Both sulfur and indium bromide plasmas at pressures of 100 to 200 kPa were tested. Contact Jin Joong Kim at [email protected].

Semiconductor laser emits at 241.5 nm

Room temperature deep-ultraviolet lasing of an optically pumped aluminum gallium nitride (AlGaN) multiple-quantum-well (MQW) laser has been reported by scientists at Kogakuin University (Tokyo, Japan). Although success when optically pumping does not automatically lead to an electrically pumped device at that wavelength, it at least indicates that materials and fabrication technologies are shaping up for that wavelength region. In this case, the laser, when pumped with pulsed 193-nm light from an argon fluoride excimer laser, emits at 241.5 nm at room temperature and 231.8 nm at 20 K.

The 450-µm-long laser cavity was defined by uncoated cleaved facets and consisted of AlxGa1-xN (Al composition x of 0.66) epitaxial layers on a silicon carbide (SiC) substrate. The researchers attribute the devices short-wavelength performance to the high quality of the MQW structure, as well as to good strain control of the AlN layer on the SiC. The strain control was achieved by inserting an AlN/GaN multibuffer-layer structure between the substrate and the AlN layer. The threshold pumping power at room temperature was 1200 kW/cm2 at room temperature, and 710 kW/ cm2 at 20 K. Contact Takayoshi Takano at [email protected].