Nanocrystal research targets optoelectronic components

An all-silicon optoelectronics technology could enable integration of traditional compound-semiconductor optical materials with standard CMOS processing.

Silicon nanocrystals are a promising candidate materials system for active devices such as modulators, optical amplifiers, and light-emitting diodes (see "Nanocrystals: quantum-mechanical optical materials," p. 79). Luminescence in nanocrystals is observed to be blue-shifted in proportion to size and generally more efficient than luminescence in bulk materials. But the stubborn persistence of the indirect bandgap in silicon leads to relatively long radiative recombination lifetimes (of microsecond order) that limit the brightness and power efficiency of silicon-nanocrystal optoelectronic devices. If the radiative emission rates for silicon nanocrystals can be further increased by plasmonic-enhanced light emission, we can begin to seriously contemplate silicon quantum dots as an alternative optical material to direct gap compound semiconductors

Surface plasmons brighten nanocrystals

The limitations imposed by the indirect bandgap in silicon nanocrystal–based optoelectronic devices might be overcome by engineering the near-field coupling between silicon nanocrystals and metallic structures. Unlike dielectric materials, metals can support surface-bound charge oscillations called plasmons, which offer unique opportunities for localizing and enhancing electromagnetic fields in nanostructures, and ultimately for extracting more light from nanocrystals. The so-called Förster energy transfer from a nanocrystal to a surface plasmon is a dipole-dipole near-field interaction that can potentially occur on nanosecond or faster time scales. This implies that excitons in nanocrystals near plasmon-supporting metal interfaces will preferentially decay by energy transfer to plasmon modes.

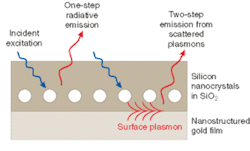

Energy stored in surface plasmons can be guided over macroscopic (millimeter-scale) distances without large scattering losses if the metallic interface is sufficiently smooth because of a momentum mismatch between the bound plasmon mode and radiative photon modes that inhibits direct coupling. To recover energy efficiently in the far field, an appropriate grating structure must be introduced to match the modes. In practice, a metallic film with nanometer-scale surface-roughness features can be used to support surface plasmons and to provide a grating to scatter light into the far field. Like the near-field coupling into the plasmon modes, scattering off this grating can be much faster than radiative emission in nanocrystals.

Coupling to surface plasmons opens a new parallel pathway for emission from silicon nanocrystals: energy transfer from the nanocrystal to the surface-plasmon mode, followed by the scattering of this energy into the far field (see Fig. 1). As the dipole-dipole interaction and scattering processes are both extremely rapid (on the order of nanoseconds) relative to the radiative emission rate of silicon nanocrystals (tens of microseconds), this two-step pathway can be much faster than the one-step process of direct nanocrystal radiative emission. Such coupling of silicon nanocrystals to metal surfaces can have the effect of leaving the emission energy unaltered while greatly enhancing the overall radiative rate and thus the achievable power efficiency. However, even coupling to surface-plasmon modes will not eliminate the need to carefully control the charge state of nanocrystals if we are to build efficient silicon optoelectronic devices.

Charging ahead

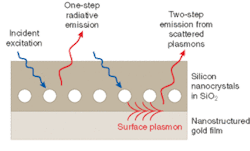

A typical silicon nanocrystal with a diameter of approximately 3 nm has a volume of approximately 1.4 × 10-20 cm3 (about 1000 silicon atoms). This implies that storing a single excess electronic charge on a nanocrystal is equivalent to doping an initially intrinsic material to a carrier concentration of more than about 7 × 1019 cm-3. Any process that depends on the presence of excess carriers will therefore be switched on and off with high efficiency by charging or discharging the nanocrystal (see Fig. 2, top left).

One such process is nonradiative Auger recombination, named after Pierre Auger, who first reported observations of the process in gases excited by x-rays in 1925. Auger recombination is a three-body process in which an electron-hole pair recombines while transferring energy to a nearby charge carrier instead of emitting a photon (see Fig. 2, top right). The process can be thought of as inverse impact ionization. Auger recombination is extremely efficient in a charged silicon nanocrystal because of the high effective carrier concentration. An exciton in a charged nanocrystal is thousands of times more likely to decay via Auger recombination than by the emission of a photon.

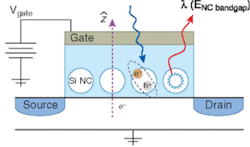

An ideal device for the study of charging effects on the optical properties of silicon nanocrystals is a nanocrystal floating-gate transistor with a transparent gate contact (see Fig. 3). Charge of either sign can be injected into the nanocrystal array via Fowler-Nordheim tunneling under an appropriate gate bias. The charge state of the nanocrystals can be measured by monitoring the threshold voltage of the transistor. A suitably transparent gate contact can be fabricated from a thin (40-nm) layer of doped polysilicon. The array of nanocrystals can be formed by ion implantation and high-temperature annealing in a completely CMOS-compatible (albeit front-end) process. We have fabricated such devices through collaboration with Intel (Santa Clara, CA) on 300-mm substrates in facilities that are used to produce Pentium processors.

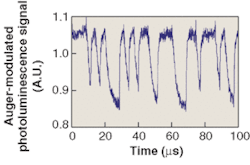

Our observations confirm that charge injection into the array of nanocrystals can be used to directly modulate the photoluminescence output of the device at speeds above 300 kHz (see Fig. 4). Modulation speed in these devices has been limited by inhomogeneity in the nanocrystal floating-gate-array geometry. The modulation speed in an ideal device would ultimately be limited by either the excitation pump rate or the electrical programming time for Fowler-Nordheim injection. Operation at speeds approaching 1 GHz may be possible with an aggressively thinner tunnel oxide.

If the tunnel oxide were made thicker, the devices would function as nonvolatile optical-memory elements. Just as the polysilicon-slab floating gate in a conventional flash memory module retains charge that is stored on it, the nanocrystals in the floating-gate array of a nanocrystal memory would remain charged after the bias was removed. Because photoexcited excitons would lose their energy to Auger recombination rather than radiative recombination, this charged state is an optical-memory state that can be detected by the absence of photoluminescence.

A modulated LED source

Ultimately, silicon nanocrystal–based optical sources must be electrically pumped if they are to be competitive with existing technology. Unfortunately, the electrical injection of electrons and holes into optoelectronic devices made with nanocrystals is more challenging than the electrical pumping of bulk and quantum-well semiconductor optoelectronic devices.

In light-emitting diodes and lasers made with bulk and quantum-well semiconductor structures, photons are generated from a continuous current of carriers that is injected into the semiconductor active medium. While light emission in these materials occurs via recombination of individual electron and hole pairs, it is relatively insensitive to the total number of carriers in the device active region. By contrast, light emission from quantum dots occurs after the injection of a discrete number of electrons and holes. Due to Auger recombination, the light-emission properties depend strongly on the total number of carriers in the quantum-dot active region. Previous efforts to electrically inject carriers into silicon nanocrystals have used traditional p-n type structures, with the optically active region containing a dense array of nanocrystals.

Relative to conventional light-emitting diodes, better control of electrical injection can be achieved in the silicon-nanocrystal floating-gate-transistor geometry previously discussed. The charge-injection process relies on the relative symmetry of the band offsets for electrons and holes between a nanocrystal and the channel valence and conduction bands. Just as electrons can be injected into the array by the application of a suitable positive gate bias, holes can be injected by applying a sufficient negative bias to the gate (see Fig. 2, bottom left).

One might expect that the previously programmed electrons would be ejected before holes are injected to the nanocrystals. The somewhat surprising result is that the array can be programmed with charge carriers of one type and then subsequently programmed with complementary charge to electrically fill the nanocrystals with electron-hole pairs. Thus, it is possible to electrically pump silicon nanocrystals with both electrons and holes from the transistor channel through a field-effect carrier injection (see Fig. 2, bottom right).

These new devices, called field-effect light-emitting devices (FE-LEDs), in contrast to traditional LEDs, do not emit light under constant current excitation, but only when the gate bias is switched from the negative hole-injection voltage to the positive electron-injection voltage (or the reverse), allowing for direct modulation of the LED at threshold levels of a few volts.

Because charge injection can be controlled in an FE-LED, it is possible to achieve a balance between the number of electrons and holes and avoid exciting carriers that do not contribute to luminescence. This approach may enable higher quantum efficiency than is achievable in traditional LED structures. In an FE-LED, energy dissipation is dominated by the switching energy of the transistor, which must go from accumulation to inversion each time a pulse of light is emitted. Our calculations suggest that power efficiencies of more than 10% might be realized with silicon nanocrystal–based FE-LEDs, which would bring competitive silicon-compatible photonics one step closer.

ROBERT J. WALTERS and JULIE S. BITEEN are graduate students in the research group of HARRY A. ATWATER at the California Institute of Technology, 1200 East California Blvd., Pasadena, CA 91125; GEORGE I. BOURIANOFF is a research program manager at Intel, 2200 Mission College Blvd. Santa Clara, CA 95052. e-mail: [email protected].

Nanocrystals: quantum-mechanical optical materials

Perhaps the most well-known problem in quantum mechanics concerns the peculiar behavior of particles that are confined in small volumes. Schrödinger's famous wave equation leads to the conclusion that particles trapped in smaller containers must necessarily be in more energetic states than particles with roomier accommodations. This "particle in a box" problem is the physics underlying the optical behavior of nanocrystals: extremely small (less than 10-nm diameter) crystalline volumes of either compound or elemental semiconductors that serve as containers for electrons and holes.

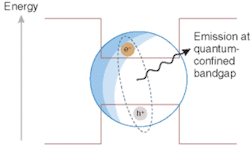

In an excited semiconductor nanocrystal, both the electron and the hole are spatially confined and are thus at higher potential energy levels than they would be in bulk crystalline material. Just as in a bulk semiconductor, the electron and the hole can bind together within the nanocrystal, forming an electron-hole pair called an exciton. When the exciton decays and emits a photon (see figure), the luminescence emission wavelength will be blue shifted because of the additional energy from the quantum confinement, a phenomenon that has been under intensive study..

Carrier confinement in nanocrystals causes the efficiency of luminescent recombination to dramatically improve as well. In the case of silicon nanocrystals, excitonic luminescence can easily be observed at room temperature in the near-IR (approximately 700 to 800 nm) that is hundreds of times brighter than the approximately 1100-nm-wavelength bulk luminescence at cryogenic temperatures. This observation is attributed to a several effects, including increased oscillator strength for radiative transitions due to the real space proximity of the electron and the hole and the low density of quenching defects in a nanocrystal and on its surface. Dramatic qualitative changes in the electronic energy-band structure of silicon nanocrystals have been largely rejected as an explanation for the improved optical properties. The experimental evidence suggests that quantum confinement does not give rise to a direct energy gap in a silicon nanocrystal. However, it has been proposed that, due to the uncertainty principle, a relaxation of the selection rule for the indirect recombination does contribute.