This is the way most engineers in optoelectronics use the World Wide Web today. You are designing an optical system, say a wafer stepper. Midway through your work, you decide you need a certain component—a galvanometer, maybe, or a light source, or a custom-made lens. So you turn to your desktop computer, calls up a search engine such as Metacrawler, and type in your needs. After examining the specification sheets found on the Web sites of a couple of companies chosen from the search engine list, you find what you`re looking for, then e-mail a request to the vendor.

This is using the Web as a source of information and a means of communication. Most companies have websites that offer details about their products and a way to place an order. E-mail has become as commonplace as the telephone. But the Web is about to become a much more useful and much more interactive tool for engineers. Already it is being integrated into optics and engineering classrooms, and use in manufacturing is only three to five years away, experts say.

Web tools at work

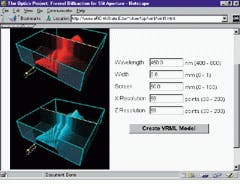

At Mississippi State University (Starkville, MI), students can take advantage of The Optics Project (TOP), an interactive computer graphics system that runs simulations of optical phenomena (see Fig. 1; URL: www.gifrc. msstate.gifdu/~foley/newtop). By accessing the TOP website, students can work with any of seven modules. For instance, a module on Fresnel diffraction allows the user to adjust the aperture of a single-slit, double-slit, or circular Fresnel diffractor and see the resulting intensity pattern. A picture of a three-dimensional box is displayed with the slit at the front and the projected pattern on the back wall. The user clicks the cursor over a red cone and drags the mouse to create either a wider or narrower aperture, with the pattern changing accordingly. The directors of TOP, John Foley and David Banks, say this interactive method gives students a better feel for the lesson being taught than still pictures in a textbook or even educational software, which is not so interactive.

While the Mississippi State project is simulation, a project at Boston University's Center for Photonics Research (Boston, MA) allows students to work with an actual Michelson-Morley interferometer over the Web (URL: orange.bu.gifdu) in a project supported by the National Science Foundation (Arlington, VA) and Melles-Griot (Cambridge, England). An interferometer sits on an optical table, and students accessing it from their computers can determine the scan size, set the step size of the moving mirror in the arm of the interferometer, determine the wavelength of the light they want, and get a video of the results.

Bennett Goldberg, a professor of physics at the BU photonics center, says the setup is not very sophisticated, but it provides an important addition to students' education. "While interferometry may be a relatively simple idea, I bet there's tons of people who learn about it and never do it," he said.

The Illinois Institute of Technology (IIT; Chicago, IL) has started a project to develop remote-controlled engineering over the Web (URL: Weblab1.iit.gifdu). Although not specifically related to optoelectronics, the project will allow engineering students to run experiments at a distance. Already anyone with Internet access can run the Online Can-Crusher in real time. Pushing a button on the IIT Web page triggers a set of solenoids to move a can into position, then pressurize a pair of cylinders that push two plates together to crush the can. A charge-coupled-device camera takes images of this process, which are then displayed on a new Web page and can be e-mailed to the user. Another, slightly more useful, device on the same Web page can measure the airflow from an oscillating fan based on parameters set by the user. A graph depicting the results is displayed and the data e-mailed (see Fig. 2).These are just demonstrations of how a Web-based laboratory could work, says Michael Hites, IIT assistant professor of mechanical and aerospace engineering and interim director of computing and networking services. The first labs are available to students in this spring semester. Because the software that controls his systems is the commercially available LabView from National Instruments (Austin, TX), he expects Web-based laboratories will become common, once the Internet has sufficient bandwidth to handle them.

Telemanufacturing a goal

With optical equipment becoming ever more expensive and the people who use it geographically diverse, access to it via the Internet is going to become more important, says Ashuman Razdan, technical director of the Partnership for Research in Stereo Modeling (PRISM) at Arizona State University (Tempe, AZ). One aim of PRISM (URL: surd as.gifas.asu.gifdu/prism), unrealized so far, is to develop telemanufacturing, in which design teams at various locations could collaborate on a model, transfer the information to a manufacturing facility, and produce a model through rapid prototyping (RP).

There are a number of RP techniques, which use, for instance, a laser to polymerize a liquid or to fuse a powder in successive layers, building up a physical model of an object that exists only in a computer-aided design (CAD) program. "It's hard to have all [the techniques] in one place, unless you're very rich," Razdan said.

He envisions a consortium of RP machines located in different states and all hooked into the Internet. If an engineer in Arizona needed a certain method of rapid prototyping and it was only available in California, for instance, the computer would send the design to the California machine, and the resulting model could be delivered to the engineer by express mail. Or if the engineer wanted the model composed of three different materials, three machines in separate locations could make the appropriate pieces. For the engineer, the process should be no more complicated than printing a document from his or her desktop computer.

"It doesn't matter where the resource is located. As long as your part shows up at your door two days later, you don't care if it was manufactured locally or in Ann Arbor, MI, or in Fresno, CA," Razdan said.

Arizona State also has an NSF-funded program, Interactive Nano-Visualization in Science and Engineering Education, that allows remote operation of a scanning probe microscope and an atomic force microscope (URL: see materials.eas.asu.gifdu/invsee). Physics teachers in high schools and community colleges can sign up to run experiments remotely for their classes. Taking it a step further, the Nanomanipulator Project at the University of North Carolina (Chapel Hill, NC) combines virtual-reality techniques with Internet access (URL: www.cs.unc.edu/Research/nano) to allow students not only to see but to feel materials using the university's scanning probe microscope (see Laser Focus World, May 1994, p. 145).

"I think the real jump is going to be from information flowing in one direction to information flowing in both directions, or in multiple directions," Razdan said. When people can interact with machines over the Web with the same type of instant response they get talking to people on the telephone, "that's when I think it will take it to another level."

Boston University's Goldberg said that companies currently providing specification sheets and e-mail links on their websites will eventually give potential customers the opportunity to try out equipment over the Web before they buy it.

"If you're going to buy a $5000 spectrometer, you would like to be able to go out and take it for a test drive and push buttons on it, and ultimately you should be able to do this remotely," Goldberg said. Companies will not have any choice but to accommodate such desires, he predicted.

"In five years, if you don't have a website that is interactive, you'll be largely ignored," he said.

About the Author

Neil Savage

Associate Editor

Neil Savage was an associate editor for Laser Focus World from 1998 through 2000.