With each passing year, researchers have pushed laser performance to new levels in power, pulse length, tunability, and efficiency. At the same time, they have expanded the range of wavelengths at which various types of lasers can emit. Feeding on these results, engineers have expanded the scope of laser applications in research, materials processing, telecommunications, and more.

Four basic properties make lasers suitable for such diverse applications. They can generate extremely high power and intensity (deliver a large amount of energy to a small spot size), and they can be guided swiftly and precisely. In addition, the emitted light can have high spectral purity within a very narrow bandwidth, and it is coherent, with all wavefronts in phase.

No one laser offers all of these properties to the same degree, though. The highest-intensity lasers producing extremely short pulses of light must, by the laws of mathematics, have extremely broad bandwidths and be highly incoherent. The most spectrally pure of the coherent lasers tend to have low power outputs. Such trade-offs in properties are why various types of lasers work better in different applications.

In the following months, this series on advanced applications will review key fields, including interferometry, image recording, marking, spectroscopy, materials processing, data storage, micromachining, rapid prototyping, and telecommunications. It will examine how and why lasers may be the best tools to solve specific problems in these applications, discuss competing technologies, and explore future trends in each field.

Power principles

Specific applications can benefit from a particular laser capability, such as high power intensity. For example, the highest power intensity is delivered by ultrafast-pulse Ti:sapphire lasers. At intensities beyond 1015 W/cm2, pulses can ionize nearly all the material within the focal spot before there is any significant heat conduction or mass flow. Micromachining benefits because the region around the focal spot is almost unaffected by the laser ablation, and cuts are thus extremely precise. This has allowed drilling features as small as 300 nm.

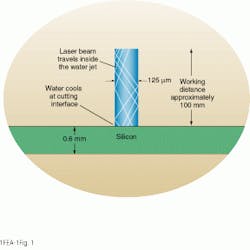

The application range of laser micromachining is extended even further when a Nd:YAG laser utilizes water as a fiber-like delivery tube (see Fig. 1). Unlike conventional laser cutting, where thermal distortion can be a problem in specific work materials, the laser beam is cooled by the water at the cutting face to reduce deformation, tempering, and related structural changes at the part edges. Applications that can benefit include micromachining of polymer medical components and drilling of silicon wafers. The reduced slag produced in each case helps eliminate secondary processing steps, such as grinding.At power-intensity levels of 109–1010 W/cm2, carbon dioxide (CO2) and solid-state lasers can meet the wide power demands of material joining, cutting, and surface treating. Carbon dioxide lasers providing up to 100 kW are competitive in the heaviest welding tasks. Combined with fiberoptic beam delivery and robotics systems, continuous-wave Nd:YAG lasers can deliver power in the single-digit kilowatt range and provide more flexible machining options than conventional machine tools. High-power diode lasers are providing efficiency approaching 40%, which can give them cost benefits even over conventional lasers in applications such as hardening of piston rings and razor blades.

Precision guidance

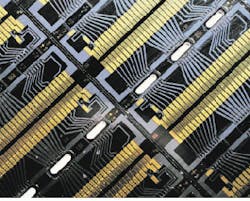

Because a laser beam has no momentum or mass, simply repositioning a small, lightweight mirror allows pointing the beam at a target with high precision and speed. This makes lasers suitable for applications requiring speed, precision, and computer control, such as laser printing. Another example is laser marking for identifying and tracking products. Unlike ink, laser marks are permanent and can be made on a variety of materials, including plastics, metals, composites, glass, paper, and rubber. Marking also is fast, with one twin-galvanometer Nd:YAG unit marking 1-mm characters at up to 600 characters/s.

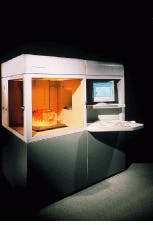

On a more advanced level, lasers have changed the traditional prototyping process dramatically. Rapid prototyping with stereolithography, for instance, can produce a prototype of a new part in hours, instead of the days or weeks required with conventional machining processes. The process builds models out of a polymer material with a computer-controlled laser (see Fig. 2).Sizing up spectroscopy

Extreme spectral purity and tunability also make lasers indispensable for many types of spectroscopy. By scanning a tunable laser across a range of wavelengths and recording the absorption or emission from a sample, spectrographs can provide far-higher resolution than obtainable with diffraction gratings and ordinary light sources. Alternatively, samples can be made to fluoresce by exposing them to laser light at narrow ranges of wavelengths. A characteristic pattern of fluorescence in response to given wavelengths of laser radiation can identify materials or make certain features stand out from a background.

An example is a system in Great Britain that relies on two-photon absorption from a solid-state laser to monitor laser-excited fluorescence that occurs as decay attacks the enamel of otherwise healthy teeth. According to the researchers involved in the project, lesions in tooth enamel are difficult to spot in the stages where the tooth can still heal itself. Fluorescent spectroscopy could help dentists spot diseased sections in time because the peak of the fluorescence is at 680 nm for healthy areas of a tooth and 550 nm for diseased sections.

Lasers also add resolution in space and time to conventional spectroscopy. Flash-imaging spectroscopy based on computed tomography allows dynamically studying spectra over a plane surface, with typical frame rates of 30 Hz, spectral resolution of 30 to 200 bands, and space resolution of 64 x 64 pixels. To study some rapid biological processes, time-resolved fluorescence spectroscopy can capture changes occurring within a time duration approaching mere hundreds of picoseconds.

Telecommunications and holography

Perhaps the most economically significant applications of lasers come from their ability to produce coherent radiation, in which all waves share the same phase. This, of course, makes them ideal for telecommunications, because the highest bit rates can be sustained when the phase of the transmission is controlled. The further development of wavelength-division multiplexing—the carrying of different wavelengths of light on the same fiber—depends on coherence and is the current leading technique in expanding communications capacities.

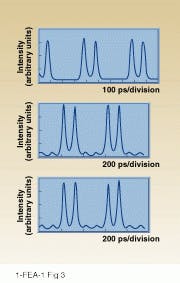

The probable next step in telecommunications, soliton transmission, depends even more on tailoring the phase of the laser pulse. Soliton transmission involves the production of high-power pulses that retain their form essentially indefinitely (see Fig. 3). Efforts are currently focusing on all aspects of fiberoptic communications to improve sources, modulators, amplifiers, fiber detectors, and switching systems to accommodate the larger capacities that are on the way.Finally, the coherence of lasers makes them a key component in many types of interferometers, particularly related to holography. Interferometers provide precision measurements based on the interference patterns of light or other radiation. Laser light can immensely extend precision of this technology. Indeed, in the Laser Interferometric Gravitational Observatories now nearing completion in Hanford, WA, and Livingston, LA, kilometer-long interferometers will be able to measure distortions in space that are a tiny fraction of the diameter of an atomic nucleus. These signals may help researchers detect gravitational waves produced by collapsing stars and other astronomical phenomena.

In more down-to-earth applications, holographic interferometers allow engineers to compare multiple holograms of a model, which could promote high-precision, nondestructive testing of a range of products. The production of holograms themselves has moved from the realm of novelty to routine application. Today, surgeons, for example, can build a multiple-exposure hologram of a patient`s skull and brain to plan and practice delicate surgical procedures via digital holography. The data for the hologram come from a CAT or MRI scan and are projected from a Nd:YAG laser to produce a brain model that seems to float in space.

Upcoming articles will look at each of these application areas, emphasizing the most important features of new research and development and the common threads that tie these fields together. As the pace of advances in laser applications continues to accelerate, such cross fertilization will become more and more an integral part of the technology.

About the Author

Eric J. Lerner

Contributing Editor, Laser Focus World

Eric J. Lerner is a contributing editor for Laser Focus World.