Vertical-cavity-laser arrays carve fast, scalable niches

Vertical-cavity-laser arrays carve fast, scalable niches

Jeff D. Montgomery and Stephen Montgomery

Part 1 of this two-part article outlines the progress of vertical-cavity-laser technology in various markets. Part 2, to appear in an upcoming issue, will focus on the economics of those markets and will discuss emerging VCL technologies--Ed.

Vertical-cavity surface-emitting-laser (VCSEL) diodes are based upon multiple-quantum-well (MQW) technology. The nomenclature of these devices is now evolving from VCSEL to VCL. Quantum-well and MQW technologies were poorly understood early on, but major advances have taken place over the past decade. This work has been done in compound semiconductor materials: binary (III-V) and more-complex combinations (ternary and quaternary). The main emphasis has been on III-V compound devices that use gallium arsenide for operation in the 840- to 960-nm range.

As the term implies, VCLs are processed vertically into the surface of the semiconductor wafer, and light is emitted perpendicular to the surface. Vertical-cavity lasers are also processed in hundreds to thousands per wafer, depending upon the size of the wafer and the spacing of the VCLs. Thus, the performance characteristics of each VCL diode can be measured while still in the wafer form, before dicing.

Edge-emitter laser diodes, in contrast, have their light propagation and emission parallel to the surface of the wafer. The edge-emitter diode wafer must be diced and an edge-emitter surface exposed by cleaving of the wafer or by precise etching before the testing and measurement can be performed.

Thus, there are major time-saving advantages in the testing of VCLs, which can be automated. And an unacceptable die can be marked for discard, before dicing. This is a substantial cost reducer, compared to the need to individually position and test edge-emitter diodes.

The main focus of VCL development over the past five years has been on VCL arrays. Due to the way VCLs are processed in the wafer, the wafer can be scribed and diced to obtain linear or x-y arrays of VCLs, limited only by the yield (unacceptability of individual VCLs). VCL line arrays with up to 64 diodes have been achieved. These line arrays and matching photodiode arrays have been applied to the design of parallel optical-interconnect links. Such links match well with the parallel outputs of digital-signal processors (DSPs).

Prior to the concept of parallel optical links, the prevailing technique for transmitting the parallel output of the DSp to the memory unit was to serialize the outputs, transmit each on a single channel, then deserialize the stream at the memory-storage stage. As DSPs have evolved to 64 bits and data rates of several hundred megabits, however, the total data stream in advanced computers has now reached several gigabits per DSP. Correspondingly, mainframe designs are evolving to increasing numbers of DSPs. This trend is challenging traditional methods of serializing, deserializing, and transporting on copper. This, in turn, has led to a pair of alternatives for transport by copper:

Serializing, then modulating onto a laser-diode transmitter with single fiber connection

Eliminating the serializer/ deserializer function with a separate transmitter/re ceiver and connecting optical waveguide for each channel of the DSP.

Speed and scalability

The first option has supported the emergence of Fibre Channel, which rapidly became popular at 250 Mbits in the mid-1980s, skipped quickly through the 500-Mbit level, and has evolved to current popularity at 1 Gbit. The second alternative has the potential of being a more-scalable, long-term solution. Each DSp connection can be transported at the maximum modulation rate of the laser diode, which is now well established at the gigabit level, under evaluation at the 2-Gbit level, and presenting longer-term potential at 4 Gbit. Thus, technology is now in hand for transport, for example, of 64 Gbit: 1 Gbit per channel p 64 VCLs in the total transmitter module. Such machines are of interest to government agencies, which led to major funding by the US Defense Advanced Research Projects Agency and other agencies for the development of such transport links and their demonstration in prototype applications. Several development programs were initiated in the mid-1980s and completed from 1996 to 1998. Many of these links are now being evaluated by computer designers worldwide. Honeywell, AMP, and Siemens are the leading suppliers of these prototypes, and Hewlett-Packard is expected to ship an evaluation product in 1999.

While it would be technically feasible to fabricate these massively parallel optical transport links with edge-emitter laser diodes, VCL arrays have the potential for achieving much lower cost per channel and per gigabit transported. The demand for these parallel links is also supported by the trend of locating the memory at relatively long distances from the DSP: meters to tens of meters. This makes the use of copper, with serializers and deserializers, more challenging for transport of multiple gigabits, although R&D is continuing to push copper transport data rates upward.

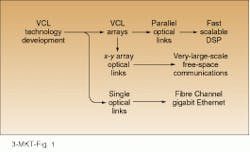

Replacing CVD lasers

The early development of VCLs for parallel optical interconnects has led to their use in single-channel optical links and in very-large-scale x-y array free-space links (see figure on p. 59). To date, most higher-data-rate single-channel optical links, such as Fibre Channel and gigabit Ethernet, have been powered by compact-video-disk (CVD) laser diodes, which are designed and processed for consumer-electronics applications. By testing and selective sorting, CVD lasers that operate satisfactorily at the gigabit level can be obtained. These are edge-emitter diodes at more than an order of magnitude lower cost than traditional telecommunication laser diodes.

With substantial production volume and fabrication experience, however, the VCL unit cost can drop below the CVD diode cost. It is expected that the VCL also will have longer lifetimes than the typical CVD laser. In addition, the VCL output beam is cylindrical, in contrast to a relatively flat-fan-beam output of the edge emitter. The edge-emitter diode, therefore, requires a complex lens, in addition to precise location of the fiber-core input relative to the lens, to achieve high efficiency of coupling.

The VCL, in contrast, requires a much less precise interface. This is especially important for optoelectronic-integrated-circuit assembly techniques, which involve automated assembly rather than operator alignment of laser diode to fiber core. This also will be a substantial cost reducer in high-volume VCL transmitter production. o

The development of vertical-cavity-laser (VCL) technology to produce VCL arrays has led directly to the fabrication of parallel optical links for digital- signal-processing (DSP) applications. The same technology is also finding its way into gigabit Ethernet and Fibre Channel applications, as well as very-large-scale free-space communications with two-dimensional arrays.