Beyond hydrogel: Stretchy PDMS optical fibers make better biosensors

Laser Focus World recently reported on the development of flexible and stretchable hydrogel optical fibers that, when injected with dye and monitored as a function of wavelength, can provide strain information that allows them to be used as biosensors in a variety of applications. Now, researchers at Tsinghua University (Beijing, China) have developed a similar biosensor using polydimethylsiloxane (PDMS) dye-doped optical fibers that works in the same manner, but is more thermally and environmentally stable than when using hydrogel fibers, which suffer from shrinkage and performance degradation unless they are used in an aqueous environment.

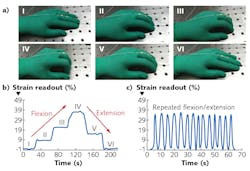

The PDMS fibers have a measured strain precision of <1% and optical loss of <0.25 dB/cm over a 450-850 nm wavelength range. Durability measurements for a 0.5-mm-diameter, 4-cm-long fiber loaded with repeated strains of approximately 100% saw no changes in fiber length, even after 500 repeat strain loads. In fact, strain loading improved to a maximum axial strain of 231% as the fiber diameter decreased. To demonstrate real-time monitoring of finger motion, a PDMS fiber was attached to a wearable glove and accurately recorded strain corresponding to flexion and extension of the fingers with no degradation after 12 cycles. The technology can be adapted to wearable smart devices, and for sport/function performance monitoring and body movement analysis. Reference: J. Guo et al., Optica, 4, 10, 1285-1288 (2017).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.