PHOTONIC FRONTIERS: Photonic power delivery: Photonic power conversion delivers power via laser beams

Life on Earth depends on photonic power delivery-the sunlight that plants use for photosynthesis-but most modern technology depends on electricity, usually delivered over copper wires. Yet it isn’t practical to transmit electricity to moving equipment, it can be difficult to transmit to remote sensors, and it is downright dangerous in the presence of explosive vapors.

Photonic power delivery offers many advantages for such applications, but it requires accepting lower efficiency and limited power levels. Power delivery that starts with sunlight has many advantages, but solar cells have limited efficiency, and sunlight isn’t available at night. An alternative is to generate artificial light, from a laser or other source, transmit it through space or an optical fiber, and then convert it into electricity. New refinements are making this alternative more attractive.

A long history

The photovoltaic effect was discovered in 1839, but the first practical silicon solar cells weren’t developed until the 1950s. The driving force was the development of artificial satellites. Batteries were cheap and easy to use on the ground, but they didn’t last long enough for satellites. Solar arrays have steadily grown in size and efficiency, and today power virtually all spacecraft in the inner solar system. Solar cells also power remote equipment that is far from power lines, and have appeared in consumer products such as outdoor lamps with internal batteries charged by solar cells during the day. Solar cells don’t even require the sun; those in your pocket calculator draw enough power from overhead lights.

It was a small and logical step to try to deliver optical power to solar cells through fiberoptics. This approach was tried for making all-optical telephones in the early days of fiberoptic communications. A single pair of copper wires delivers power and signals in traditional electrical phones, and the goal was to send power as well as signals through fibers, avoiding the need for a separate electrical power source at the phone. The concept offered the possibility of electrically isolating other equipment.

The demonstration worked, but the technology wasn’t ready to deliver enough power for practical use. Semiconductor light sources then available emitted only milliwatts of power, and solar cells convert only a few percent of the light energy reaching them into electrical energy. Yet the needs for power delivery and electrical isolation remained, and the idea of optical connections was not forgotten.

Advances in technology

Three key technical advances have changed the picture in recent years. The efficiency of photovoltaic conversion has increased as chip prices have decreased. Diode-laser power also has increased, with long-lived lasers now about to couple a watt or more of power into standard graded-index fiber with 50- or 62.5‑µm cores. And power-miserly electronics developed for consumer electronics allow engineers to do more with each milliwatt.

“A congruence of what used to be neat technology is becoming a darn good solution for [electrically] isolated power delivery and data transmission,” says Jan-Gustav Werthen, engineering director of the photonic power unit of JDS Uniphase (San Jose, CA), which last year acquired the company he founded, Photonic Power Systems.

JDSU’s photovoltaic cells can convert 40% to 50% of the incident light into electrical energy, significantly higher than the peak efficiency usually quoted for solar cells. One reason is that laser wavelengths are picked to match the peak response of the chip; solar-cell efficiency is typically measured across the usable solar spectrum. Most systems use silicon cells and lasers emitting up to 2 W at 830 ±15 nm, but 940-nm lasers can generate 5 W and their emission also falls in the peak response band of silicon. Fiber attenuation in that band limits power transmission to about a kilometer, but 1480-nm lasers can be used with long-wavelength photovoltaics to transmit power up to 10 km.

Another advantage of fiber delivery is that the efficiency of photovoltaic power converters increases with light intensity. Graded-index fibers can deliver a watt of power to a converter at a thousand times the intensity of unfocused sunlight.

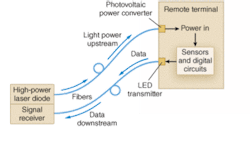

Commercial power-conversion modules deliver 2 to 12 V, at standard voltages used by electronic systems. The modules are designed to minimize power requirements, and are compact enough to fit into ST or FC connector housings. JDSU also makes an optically powered data link, which sends power upstream through one fiber, and transmits data downstream from a sensor through a second fiber (see Fig. 1).

The main uses of photonic power delivery are for sensors in environments where electrical transmission is difficult or impossible. Werthen says virtually the entire electric power industry has shifted to photonic power for measurements of direct current at the high voltages used for long-distance electric power transmission. These important measurements had required large and expensive transformers filled with oil or gas to isolate the sensor from ground potential (see Fig. 2). Fiber power delivery is simpler, easier to install, immune to lightning strikes and electromagnetic interference, and avoids transformer hazards such as oil spills and explosions.

Safety is also a critical advantage of photonic power in mines and other environments where explosive gases can accumulate, and a single spark can bring disaster. The 1996 crash of TWA flight 800, a particularly disconcerting example, was blamed on a spark from frayed electrical wires passing through the airliner’s fuel tank.

Photonic power transmission is also valuable in magnetic resonance imaging, which exposes equipment to very high magnetic fields that cause problems with electrical systems. Fiber transmission can withstand higher voltages, important because they can improve resolution. And fiber can connect to sensitive instruments measuring electromagnetic emission of consumer equipment during verification of compliance with emission standards.

Another promising application is transmitting power over spare fibers to remote nodes in telecommunication networks, including wireless transmitters and receivers. A new “Power Over Ethernet” standard calls for transmitting electrical power through wires in copper communication cables. “When we eventually migrate to fiber for bandwidth purposes, it would be really neat if power could go over that fiber,” Werthen says.

Use in free space

Fibers are convenient for photonic power delivery, but light can also deliver power through free space. Short-distance applications offer the prospect of a power version of the optocouplers used in data transmission, which isolate circuits by converting electronic signals into optical form, than back into electronic form on the other side of a gap. A laser power module could deliver a fraction of a watt across a half-inch gap this way, Werthen said.

That’s a far cry from the grandiose plans for free-space laser power transmission in the 1970s. Peter Glaser of Arthur D. Little (Boston, MA) proposed launching satellites with huge arrays of solar cells that would collect solar energy and beam gigawatts down to the ground via laser beams or microwaves. The concept was alluring during a time of energy crisis, but the technology is still decades away. It seems more feasible to beam power from large ground-based lasers to satellites when their solar arrays are in the Earth’s shadow, an idea proposed in 1991 by Geoffrey Landis of the NASA Lewis Research Center in 1991. But that technology, too, is far off.

NASA has not given up, however. In October it teamed with the Spaceward foundation to host the Beam Power Challenge competition at the NASA Ames Research Center (both in Mountain View, CA). A $50,000 prize was offered for a robotic climber that could climb at least a meter per second up a 60-m cable powered only by light from an industrial searchlight. None of the seven robots reached a meter per second, and the highest any climbed was 12 m (see Fig. 3). But the sponsors are not giving up; they’re raising the goal posts and the prize for a new contest this year. Anyone interested can find more at www.elevator2010.org/site/competitionClimber2006.html.

NASA’s long-term goal is a concept described by science-fiction writer Arthur C. Clarke in his novel The Fountains of Paradise-a space elevator that would haul material up to geosynchronous orbit. Laser power for the climber would be a nice touch. But JDSU is keeping its focus on fiber transmission and very short links through the air. With more than 10,000 systems deployed by more than 50 customers, JDSU is far ahead in the commercialization race. Yet it’s wise to remember that it’s taken a quarter of the century for the idea of photonic power distribution through fiber to get there.❏

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.