EXTREME STATES OF MATTER: Femtosecond pulses heat matter at record rates

Humans have learned to create extreme physical conditions rarely matched in the natural world; the realm for such achievements is more often than not the scientific lab. In one example, researchers at Hokkaido University (Sapporo, Japan), the Australian National University (Canberra, Australia) and the Université Bordeaux (Talence, France) are focusing ultrafast-laser pulses in sapphire crystal to heat matter at rates faster than any yet recorded-up to 1018 K/s. The pulses also create transient multimegabar pressures within the material. The intent is to use the approach as an experimental tool for condensed-matter physics.

Using a conventional tabletop femtosecond laser, the researchers focused 150 to 200 fs, 20 to 200 nJ laser pulses at 800 nm into sapphire using a microscope objective with a numerical aperture of 1.35, creating a focal spot with a volume of about 0.3 l3. The resulting intensity was greater than 1014 W/cm2, which is the threshold needed to ionize a clear dielectric early in the pulse duration. The peak pulse power of 0.5 MW was kept at less than the 1.7 MW, which would cause detrimental self-focusing in the sapphire.

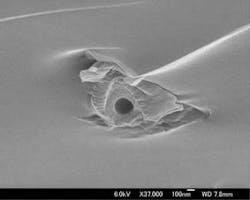

Single pulses were focused to a depth of anywhere between 5 and 50 µm. The researchers created a square array of voids, cleaved the crystalline sapphire to expose the affected volumes, then examined the results with a scanning-electron microscope (SEM; see figure). Each central void was somewhat teardrop-shaped, varied in size depending on the pulse energy, and was surrounded by an amorphous region about twice the diameter of the void. A central void appeared only for pulses greater in energy than about 20 nJ. The diameter of the amorphous region around the void reached about 500 nm for a pulse energy of 100 nJ (the researchers established the size of the amorphous region by etching; in hydrofluoric acid, amorphous sapphire etches more quickly than crystalline sapphire). From conservation of mass, it was determined that the amorphous material had a density 1.14 times that of crystalline sapphire.

The size of the amorphous region corresponded to the volume through which the expanding shock wave traveled; as it grew, the shock wave decreased in energy density until at last it ceased to exist. What remained was an ordinary spreading sound wave that caused no further alteration of the sapphire. The teardrop shape of the affected region was related to spherical aberration in the incoming wavefront caused by the microscope-objective immersion oil, which had a lower refractive index than the sapphire.

Multiphoton (six or more photons) ionization combined with electron-impact ionization caused breakdown of the sapphire into plasma (which, for a short time, still had the density of solid sapphire) in the first few femtoseconds of the pulse; the plasma absorbed light readily. Pressures higher than 10 TPa and temperatures to 5 x 105 K were reached, with heating and cooling rates reaching 1018 K/s.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.