FIBER OPTICS: Laser spark plug heads to patent office

Researchers at Colorado State University (CSU; Fort Collins, Colorado) have filed a patent application for a fiber-guided-laser method of spark delivery in large-bore natural-gas engines.1 The method could potentially enable multiplexing of one laser source to several engine cylinders, improve engine efficiency and ignition-system reliability, reduce pollutant output, and enable real-time optical monitoring of in-cylinder combustion parameters.

The concept of using lasers to initiate combustion is nearly as old as pulsed lasers, according to Azer Yalin, an assistant professor in the department of mechanical engineering. Yalin is a co-leader the CSU research group with Bryan Willson at the Energy and Engines Conversion Laboratory (EECL) at CSU. European researchers are working around these problems with systems that require a laser in each engine cylinder (see www.laserfocusworld.com/articles/214675). But the CSU team is focusing on a system in which a single remote laser source can be multiplexed through optical fibers to provide ignition in numerous engine cylinders. Fiberoptic delivery poses a significant challenge, however, because of the need to deliver an optical beam at high energy and high optical quality (low M2).

Hollow-fiber delivery

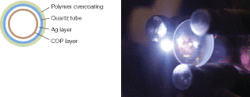

In the course of searching through possibilities, the CSU researchers encountered flexible cyclic olefin polymer-coated silver hollow fiber under development at Tohoku University (Sendai, Japan) for medical and dental applications. For testing to date, they primarily used fibers with an inner diameter of 700 µm and a length of 1 m, coated for optimal transmission at 1064 nm. For benchtop spark-delivery tests, the fundamental 1064 nm beam of a Q-switched Nd:YAG laser with a pulse duration of 8 ns, a repetition rate of 5 Hz, and near-diffraction-limited spatial quality was used to launch the laser light into the fiber through a single lens, and a lens pair was used to focus light exiting the fiber into a small spark-forming spot (see figure).2

The collaborators also successfully tested the system in one cylinder of an in-line six-cylinder Waukesha VGF turbocharged natural-gas engine at the EECL. The remaining cylinders ran with conventional spark ignition. Zero misfires were detected in the laser cylinder, demonstrating 100% reliability in the spark creation and ignition. In addition, the laser-ignited cylinder had the highest average peak pressure and one of the lowest coefficients of variation of peak pressure in the cylinder. The laser-ignited cylinder also reached 10% mass fraction burned at an angular point several degrees before any other cylinder, even though ignition timing was retarded by six degrees relative to the other cylinders.3

Not for cars

The researchers do not envision laser-ignition systems in automotive engines, in which lasers cannot compete with the much lower cost of conventional spark plugs. The focus instead is on large-bore gas engines manufactured by companies such as Caterpillar (Peoria, IL), Cummins (Columbus, IN), and Waukesha Engine Dresser (Waukesha, WI) for applications such as power generation and natural-gas pumping.

By using appropriate lenses to focus the laser beam, the spark can be located at the desired (optimum) location within the engine cylinder. Additionally, at the high in-cylinder pressures at which these engines operate, laser sparks actually become easier to produce, while conventional spark-plug performance is limited by factors such as dielectric breakdown. Laser ignition can also extend the lean limit of the combustion process to nearer the flammability limit for a minimum fuel-air mixture.

The primary focus for the CSU team is to move the work from a research environment to a commercial system. Current efforts include extending the work to multiple cylinders, investigating alternative fiber methods such as photonic-crystal fibers and fiber lasers, and investigating the possibility of analyzing light returning along the same fiber to provide real-time diagnostic information on the combustion process.

Argonne National Laboratory (Argonne, IL) and the National Energy Technology Laboratory are also pursuing related research.

REFERENCES

1. U. S. Patent Application 20060055925, March 16, 2006.

2. A. P. Yalin et al., Optics Lett. 30(16) 2083 (Aug. 15, 2005).

3. A. P. Yalin et al., Proc. ICEF 2005-2336, ASME Internal Combustion Engine Division 2005 Fall Technical Conference, Sept. 11-14, 2005, Ottawa, Canada.

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.