Cost-effective and compact nanometer-scale-spatial-resolution imaging tools are in great demand for applications in nanotechnology. Although expensive and bulky photon-based microscopy systems that use soft-x-ray illumination from a synchrotron source can provide 15 nm spatial resolution, researchers at the National Science Foundation Engineering Research Center for Extreme Ultraviolet Science and Technology and the Department of Electrical and Computer Engineering at Colorado State University (Fort Collins, CO), the Center for X-Ray Optics at Lawrence Berkeley National Laboratory (LBNL; Berkeley, CA), and the University of California, Berkeley (Berkeley, CA), have developed a widely accessible tabletop microscope with sub-38 nm spatial resolution.1

The compact microscope combines a tabletop 13 nm soft-x-ray laser with zone-plate optics to achieve the high-resolution images in exposure times as short as several seconds. The 5 Hz repetition-rate tabletop laser can generate highly monochromatic light with microwatt average power levels. The laser light is collected by a condenser zone plate and focused onto the pattern under test. An objective zone plate then forms an image of the pattern on a back-illuminated 2048 × 2048 pixel CCD array (13.5 x 13.5 µm pixels).

The extreme-ultraviolet (EUV) laser light is generated by amplification of spontaneous emission through population inversion of colliding electrons in a line-focus laser-created plasma. The plasma is created by heating a 4 mm long slab target at grazing incidence with a high-intensity pulse from a chirped pulse-amplified Ti:sapphire laser.

Zone plates were fabricated using electron-beam lithography by Weilun Chao at UC Berkeley. The 5 mm diameter condenser zone plate has 12,500 zones decreasing in width down to 100 nm, a numerical aperture of 0.07, and a focal distance of 38 mm for a 13.2 nm wavelength. Two different objective zone plates were used. One has a 0.2 mm outer diameter and 625 zones with an outermost zone width of 80 nm. The other has a 0.1 mm outer diameter and 500 zones with an outermost zone width of 50 nm.

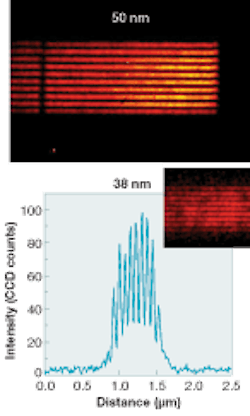

To evaluate the performance of the microscope, the research team fabricated (using electron-beam lithography) test patterns consisting of thin metallized membranes with alternating lines and spaces in a 1:1 ratio with half periods ranging from 310 nm down to 38 nm, as well as 64 radial spokes decreasing in width down to approximately 40 nm as they converge towards the center of the circular pattern. Defining the spatial resolution as the half period of the smallest set of dense lines for which the modulation depth in the image’s intensity profile is 26.5% or better (Rayleigh-like modulation), and including zone-plate specifics of the microscope system, the calculated theoretical spatial resolution limit of the tabletop microscope is 32 nm.

In a practical experiment using the horizontal lines of the test pattern, the spatial resolution was determined to be better than 38 nm (see figure). By using an objective zone plate with a smaller outermost zone width (on the order of 20 nm) and increased numerical aperture, the researchers estimate that a spatial resolution of 15 to 18 nm could be achieved. Research scientist Georgiy Vaschenko, who works on the project in collaboration with professors Carmen Menoni and Jorge Rocca at Colorado State University, and professors Eric Anderson and David Attwood at UC Berkeley, says this new microscope evolves from a similar system recently demonstrated by the same group that uses light from a capillary-discharge 46.9 nm laser to achieve a resolution from 120 to 140 nm.2, 3 Future plans include demonstrating the operation of the instrument in a reflection mode to inspect surfaces, for applications such as defect imaging in EUV lithography masks.

REFERENCES

1. G. Vaschenko et al., Optics Letters 31(9) 1214 (May 1, 2006).

2. G. Vaschenko et al., Optics Letters 30, 2095 (Aug. 15, 2005).

3. F. Brizuela et al., Optics Express 13(11) 3983 (May 30, 2005).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.