SILICON PHOTONICS: Race heats up for the silicon laser

Will lasers be integrated into standard CMOS processing by 2010? A number of folks with widely different approaches and U.S. Department of Defense (DOD) funding seem to think so. A multi-university research initiative (MURI) administered out of the Massachusetts Institute of Technology (MIT) Microphotonics Center (Cambridge, MA) was awarded a $3.6 million DOD grant in August targeted at demonstrating an electronically pumped silicon (Si) laser in three years. If successful, the grant will be extended by two more years and $2.4 million more in funding to actually integrate the devices into a CMOS process.

In July, researchers at the University of New Mexico (Albuquerque), with funding from the Defense Advanced Research Project Agency (DARPA; Arlington, VA) and Air Force Office of Scientific Research (Arlington, VA), were predicting imminent lasing of self-assembled, strain- and crack-free, III-V compounds on the same 001 silicon orientation used in CMOS processing. Also in June, the team-funded by DARPA and Northrop Grumman (Los Angeles, CA)-at the University of California Los Angeles (UCLA) that first reported optically pumped silicon lasers, which are currently under development at Intel (Santa Clara, CA), described a significant reduction in power consumption of optically pumped silicon lasers. In coming years, optoelectronic history may remember the past few months as the first of many hot summers for lasing in silicon.

Two approaches

Jürgen Michel, one of nine principal investigators for the MURI, which includes eight universities in the U.S. and four universities outside the U.S., said the collaboration, led by Lionel Kimerling at MIT, would focus on two different routes to an electronically pumped silicon laser. One involves an active germanium layer deposited on silicon. The other involves nanocrystalline silicon and erbium. “The idea of a silicon laser has been around for 15 or 20 years,” he said. “And during the last few years progress in understanding nanocrystalline silicon and its effect on erbium has led to the prospect of actually realizing it.” Substantial funding is also available to develop the technology, he added. “It helps when these things come together.”

A different approach to integrating electronically pumped lasers into CMOS is being pursued at the University of New Mexico, where researchers are growing III-V optical materials on the same (001)-orientation silicon used in standard CMOS processing. As of July, they had demonstrated optically pumped VCSELs and edge-emitting lasers, as well as p-n junctions with the very low leakage currents needed to make diodes. And they were optimistically predicting imminent diode-laser growth.

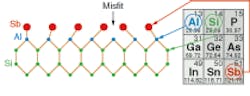

In the New Mexico method, however, the cracks and strains that are usually produced at material interfaces due to differences in atomic size are relieved by a self-assembly process in which the two materials spontaneously skip bonding sites with a periodicity that enables them to align and bond with one another stress free, without the need for a transitional buffer layer of distorted material. So in the case of a 13% lattice mismatch between silicon and aluminum antimonide, one bond in every eight is skipped (see figure). Project leader Diana Huffaker, at the University of New Mexico, likened the self-assembly process to a heterogeneous distribution of different size marbles that can occur when they are packed together under appropriate conditions.

In addition to differing from previously reported growth of III-V lasers on silicon by maintaining the same silicon orientation used in CMOS processing, the New Mexico work also appears to circumvent key material and process mismatch issues. The thermal expansion coefficient of silicon (2.05 × 106/cm2) is much better matched to aluminum antimonide (2.55 × 106/cm2) than it is to gallium arsenide (GaAs: 6.05 × 106/cm2). Also unlike the growth temperature of GaAs in excess of 510°C, the growth temperature of III-antimonide compounds at less than 450°C is CMOS compatible. In addition, the size difference between antimony and silicon atoms, which is much larger than the difference between silicon and arsenic atoms, seems to facilitate spontaneous self-assembly.

The researchers fabricated a very thin aluminum antimonide (AlSb) layer nucleated on Si and measured a very low defect density compared with GaAs. They have demonstrated room-temperature, optically-pumped in-plane and vertically emitting lasers, as well as a p-n junction with leakage current of less than 10 µA at 10 V. The latter was enabled by the elimination, through an annealing process, of anti-phase domains (APD), which form a low-resistance path in III-V materials on Si causing diode leakage. While APDs can also be eliminated using miscut Si wafers, Huffaker said, the annealing process enabled maintenance of CMOS-oriented Si. Diode lasers are currently under development, she added.

Meanwhile, in Bahram Jalali’s laboratory at UCLA, where the first silicon laser and optically pumped device based on Raman amplification was demonstrated two years ago, researchers have used the nonlinear photovoltaic properties of silicon amplifiers to actually recycle lost power and eliminate inefficiencies in optically pumped silicon lasers caused by two-photon absorption (see www.laserfocusworld.com/articles/259067).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.