FMCW LiDAR is the future of high-performance sensing

In today’s world, sensing technology is shifting faster than at any point since the early days of radar. And while LiDAR has become synonymous with autonomous vehicles, its impact is now extending across aerospace, defense, industrial automation, and long-haul transportation. What’s driving this acceleration? The rapid transition from time-of-flight (ToF) LiDAR to frequency-modulated continuous-wave (FMCW) LiDAR—a transition that will fundamentally reshape the safety, capability, and performance of modern sensing systems.

For the environments in which we now operate—vehicles moving at highway speed, aircraft navigating complex airspace, or autonomous systems interacting with unpredictable human behavior—the expectations for sensing precision are dramatically higher than even a decade ago. FMCW LiDAR advances these capabilities to meet these expectations.

ToF vs. FMCW: Why shift?

The first step is to understand why FMCW represents a dramatic improvement over conventional ToF systems.

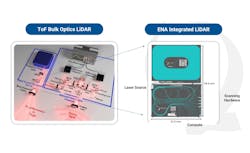

ToF: A strobe-light analogy. As shown in Figure 1, ToF LiDAR works much like a strobe camera. A flash of light is emitted, its reflections are captured, and a point cloud is assembled one frame at a time. Comparing these frames reveals motion, akin to watching a strobe light illuminate a moving hand inside a dark room.

It’s a well-understood method, but has natural limitations: Its range degrades quickly as the pulse spreads; resolution diminishes sharply at distance; motion must be computed across multiple frames; and performance suffers within adverse optical conditions.

FMCW LiDAR: Continuous beam, continuous insight. FMCW LiDAR is a fundamentally different approach. Instead of a bright pulse of light, it sends out a continuous, frequency-modulated beam and measures the precise shift in frequency as the light returns. This shift—rooted in the Doppler effect—provides instantaneous data not only about where objects are, but how fast they are moving relative to the sensor.

It results in instantaneous velocity and distance measurements; significantly higher range and resolution; superior accuracy in all lighting and weather environments; long-distance performance using coherent laser light; and more reliable detection even if objects blend into their background.

The ability to capture motion and location simultaneously—and at long range—is a decisive advantage for safety-critical autonomous systems.

Cameras and ToF alone fall short

Many consumers assume cameras should be sufficient for autonomy because humans drive with vision. But humans are also susceptible to optical illusions, and cameras inherit the same weaknesses.

One of the most widely circulated examples shows a camera-only system failing to detect a tractor-trailer because the trailer matched the color of the sky behind it. Even as a pedestrian waves at the vehicle to stop, the system misinterpreted what it saw.

ToF improves on this, but still shares major limitations: Reduced range due to eye-safety power constraints, degraded resolution at distance, and multiframe latency to calculate object velocity. FMCW overcomes many of these limitations entirely.

Integration: The real story behind falling costs and LiDAR adoption

A decade ago, FMCW LiDAR was considered too expensive and complex for mainstream adoption. The systems relied on bulk-optic assemblies with numerous discrete components—higher cost, higher failure rates, and greater manufacturing variability. This has changed dramatically (see Fig. 2).

Wafer-scale photonic integration. Just as the semiconductor industry moved from discrete transistors to highly integrated chips, LiDAR is undergoing the same transformation. FMCW systems are now being built on photonic integrated circuits, which reduces system size, cost per unit, power consumption, optical alignment complexity, and failure points. The only remaining external elements are the laser source and beam-steering module.

Dramatic improvements in tunable lasers. During the past three years, tunable laser production capacity has surged and costs have dropped significantly. Laser quality and availability are no longer barriers to FMCW manufacturing at scale.

Solid-state advances. A new generation of solid-state FMCW LiDAR systems integrate scanning, modulation, and detection directly into a single device—and it increases reliability to automotive-grade or better.

It’s precisely why costs are falling and adoption is accelerating far faster than anyone predicted.

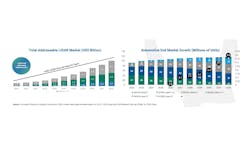

Automotive adoption: Two years ahead of schedule

Adoption of both ToF and FMCW LiDAR is borne out by the latest market figures (see Fig. 3)—the LiDAR market is expanding faster than forecasted. In 2025, industry revenue is expected to reach $7 billion, nearly two years ahead of previous projections. This growth is driven primarily by the automotive sector.

Nearly every global automaker—Mercedes, Toyota, Hyundai, BYD, GM, Ford, and others—are integrating LiDAR into next-generation vehicles. The only notable exception is Tesla, and even their position may eventually change.

Front-facing LiDAR will soon be standard on nearly every make and model, while rear and side LiDAR will increasingly appear on mid- to high-end platforms. FMCW’s performance advantages make it a clear long-term choice for safety-critical automotive systems.

Power, thermal management, and the importance of photonics platforms

Power consumption is one of the most critical differentiators between ToF and FMCW architectures—especially for electric vehicles, where every watt of load directly reduces driving range. This is where the choice between three main photonics platform becomes decisive.

Planar light wave circuits (PLCs), the platform Enablence specializes in, offer a uniquely powerful combination of efficiency, stability, and scalability. PLC technology does not require the thermal tuning overhead of silicon photonics or suffer from thermal drift challenges that plague other material platforms. The result is a photonic architecture that maintains optical performance across extreme automotive temperature swings (while consuming dramatically less power).

Silicon photonics requires constant thermal tuning to maintain wavelength stability, which adds significant power overhead and system complexity.

Silicon nitride offers good optical stability, but typically requires hybrid integration and does not match PLC’s intrinsic thermal efficiency at scale.

Because FMCW LiDAR extracts velocity directly from the coherent signal, its compute requirements are inherently lower than ToF systems, which must run large, power-hungry AI inference stacks to interpret captured frames. When combined with the exceptional power efficiency and thermal resilience of PLC photonics, FMCW LiDAR delivers longer range with lower total system power. The result? FMCW delivers longer range with lower total system power, which is critical for EVs.

Regulation: A coming wave favors FMCW

Today, regulatory requirements for LiDAR are modest and focus primarily on eye-safety limitations. But this landscape is about to change.

With more than 2,000 camera-related safety incidents involving current systems under review by the U.S. National Transportation Safety Board, it’s increasingly clear that camera-only or camera-radar approaches can’t reliably deliver the safety levels required for widespread autonomy.

Based on privacy and safety precedents in other sectors, we should expect mandatory multimodal sensing, requirements for long-range detection, and potential standards specifically favoring FMCW accuracy.

New regulations—particularly in Europe and the U.S.—coming within the next 36–60 months will significantly accelerate FMCW adoption.

The ‘LiDAR’ road ahead?

LiDAR adoption will intensify, and the advantages of FMCW LiDAR are clear: Superior range and resolution; instantaneous velocity measurement; higher reliability and safety; lower power consumption; strong performance within adverse conditions; and lower compute requirements.

The combination of cost reduction, integration, and performance makes FMCW LiDAR not just an improvement, but an inevitable next step in sensing technology.

At Enablence Technologies, we’re proud to help drive this evolution. As more manufacturers integrate advanced photonics, and as the market shifts toward solid-state FMCW LiDAR platforms, we’re entering a new era—one in which sensing will become as reliable and predictable as the roads and airways demand.

This technology will save lives, enable safer transportation systems, and expand the boundaries of what autonomous machines can achieve. And it’s happening now—faster than anyone expected.

Editor's note: Listen to our podcast interview with Todd Haugen below, which we released on February 25, 2025.

About the Author

Todd Haugen

Todd Haugen is CEO of Enablence Technologies, a supplier of optical chips based on PLC technology serving datacom, telecom, automotive, and artificial intelligence (AI) applications.