Understanding spectrally controlled interferometry

The helium neon (HeNe) laser’s long temporal and spatial coherence enabled simple Fizeau interferometers to be viable and easy to use. The laser diode and scanning laser diodes introduced new methods of acquiring data, but little else.

These long coherence lasers produce fringes everywhere, so finding the fringes is easy. Unfortunately, any optical surface in the interferometer, reference element or measured part, plus scratches or dust, produce fringes that degrade the measurement performance. Much effort is expended, every day, to overcome these limitations.

Laser acquisition improvements, not game-changers

Several methods marginally improve the situation. White light can be adapted to Fizeau interferometers with a delay line, but are hard to use. White light fringes are nearly impossible to find in a Fizeau interferometer with a delay line. To overcome this limitation, a long coherence laser must be used to align the surface.

Scanning laser diodes using Fourier analysis hunt for separate interference cavities via the fringe modulation beat frequency. Long cavities modulate faster than short cavities in the presence of a constant wavelength shift. The math finds the surface of interest and the user must trust the algorithm, as they never directly view the interference fringes. Further, these beat frequencies are disturbed by scanning nonlinearities, environmental vibration, and air turbulence.

To find a surface, the beat frequency must be precisely known. To minimize environmentally induced errors, nearly a thousand data frames must be acquired to hopefully zero in on the correct frequency. This makes measurement times long, especially for short cavities. These technologies have been incremental improvements, but are not game-changing.

A hint of a new direction was demonstrated in 1997 by Professor Schwider with his paper titled “White-Light Fizeau Interferometry.”1 By creating a spectrum of light as the input source, Fizeau fringes distant from the reference surface were produced that did not have the spurious fringe problems associated with laser Fizeau interferometry. This approach isolated the fringes to one cavity optical path length, but it languished because the technology to produce the required input spectra did not exist. Plus, a practical source would create white-light Fizeau fringes adjustable to various cavity lengths, while enabling easy alignment and use.

Enter spectrally controlled interferometry (SCI)

The answer came 15 years later with new concepts to create and electronically control the spectrum.2 Importantly, the interferometer does not need to change, as SCI transforms any interferometer. This technology is now commercially available.3 Here is how it works:

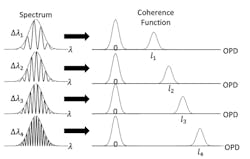

Spectral temporal coherence control. The spectral wavelength bandwidth determines coherence depth. In the single-frequency mode, an SCI is a long temporal coherence laser, making alignment easy. Widen the spectral bandwidth and it acts like a white light source (see Fig. 1). In the white light mode, the fringe depth can be controlled with a minimum length of ~0.15 mm, enabling 0.075 mm surfaces to be measured. The SCI has the benefits of both the HeNe laser and white light source, the best of both. SCI can be used with both plano and spherical cavities—there is no limitation.

Spectral cavity selection. With SCI, the frequency of the spectrum determines the cavity to be measured (see Fig. 2). With a low-frequency spectra (few lines), the cavity selected is short. With high-frequency spectra (many lines), the selected cavity is long. In this way, SCI selects the one cavity that displays interference fringes. The desired cavity length is selected electronically by controlling the spectral lines that position the fringes.

Once selected, the fringes on the surface of interest are observed live, as opposed to Fourier methods that extract surface data mathematically. You know what you’re going to measure, you see the fringes, and have an a priori expectation of the approximate shape.

Spectral phase shifting. To measure a surface or wavefront, the phase of the cavity—pixel by pixel—must be measured. This is traditionally performed by phase-shifting interferometry, where the cavity phase is modulated and discrete Fourier analyses calculate each pixel phase. Cavity modulation is induced by mechanically moving the reference or linearly modulating the wavelength. With both, averaging to minimize environmental influences is time-consuming since both data acquisition and phase calculation are required for several measurements to be averaged for a final result.

With SCI, the fringe phase is modulated by modulating the phase of the SCI spectrum (see Fig. 3). Uniquely, all cavity spacings modulate in step with the spectrum phase. Therefore, a 0.075 mm cavity modulates at the same rate as a 2000 mm cavity. Since the phase shift is electronic, it is linear and precise.

SCI can also continuously phase-shift without limitation, which enables a new data acquisition mode—spectrally synchronized acquisition.

Spectrally synchronized phase measurement. A new method of phase acquisition is enabled by SCI, called spectral synchronized phase shifting. The cavity phase can be continuously phase-shifted because there are no mechanical or physical limitations to the number of modulations. Phase is shifted at a precise frequency for as long as desired. Knowing the phase-shifting frequency enables synchronously extracting the phase, minimizing environmental influences.

With a 180 Hz data acquisition, 100 frames of modulated phase data is acquired in less than 600 ms, resulting in tens of picometer-level acquisition noise. This speed and noise level are important for high-end optical production, extracting low signal/noise data from low-reflectivity surfaces or low-contrast fringes, and the measurement of mid-spatial frequencies that typically have nanometer heights.

SCI transforms optical test interferometry with its combination of electronic coherence control (laser alignment and white light measurement), cavity selection, back-reflection rejection, real-time fringe viewing, and spectral synchronized phase measurement. Fizeau interferometry has been given new capabilities that are required for process improvement and manufacturing control of today’s optics.

Example applications

Accurate surface measurement: Standard surface measurement without background interference.

Mid-spatial frequencies: SCI combined with spatial coherence control enables picometer, low-noise measurements required to measure fine mid-spatial frequency on surfaces.4

Substrate characterization: Directly measure surface front, back, total thickness variation, and thickness in one setup electronically, without any surface preparation. Users note saving hours in the measurement of substrates with the elimination of painting, taping, or greasing the offending surfaces.

Domes: Measure the S1, S2, thickness, and offset between the two.

Extremely thin substrates: Measure substrates down to 0.075 mm in normal practice.

Directly measure substrate stacks: Measure more than 35 plate stacks directly, measure one surface, electronically move the fringes to the next surface, and measure…one by one. With spectral synchronized acquisition, the low signal-to-noise does not affect the measurement quality.

Potential future applications

Direct radius of curvature: Measuring radius of curvature while measuring surface form, eliminating multiple error sources and speeding the measurement.

Lens center thickness: Lens thickness along with surface form, mid-spatial frequency, and radius might all be measured in the same setup for optimum lens quality control.

Lens assembly spacings: Measure the vertex spacing between surfaces in a lens assembly.

Spectrally controlled interferometry changes what to expect from interferometry. It transforms 150 year-old Fizeau technology into a state-of-the-art instrument.

REFERENCES

1. J. Schwider, Appl. Opt., 36, 7, 1433–1437 (Mar. 1, 1997).

2. A. G. Olszak, “Optical Coherence Tomography Using Spectrally Controlled Interferometry,” U.S. Patent 8,675,205 B2 (2013).

3. See https://apre-inst.com/products/sci.

4. P. Szwaykowski, “High Quality Measurements of Mid Spatial Frequencies in Optical Surfaces,” Optica, Optical Fabrication and Test conference (Jun. 2023).

5. See https://apre-inst.com/laser-fizeau-interferometer-history.

About the Author

Robert Smythe

President, Äpre Instruments

Robert Smythe is president of Äpre Instruments (Tucson, AZ).