Autonomous vehicles, lasers, artificial intelligence (AI), drones, GPS—all things not typically associated with farming. In fact, advanced technology and traditional farming have historically resided near opposite ends of the spectrum. Times change, and it turns out they’re a perfect match.

Implementing advanced technology systems offers a near-immediate benefit for farms, because labor shortages are prompting farmers to seek alternative ways to remain in business and be successful. “Things have been tough,” notes Willy Pell, VP of Autonomy and New Ventures at Blue River Technology (Sunnyvale, CA), a division of John Deere.

There are “these ‘duct tape and baling wire’ situations that people—farmers—are holding their businesses together with right now,” he says. Advanced technologies such as autonomous tractors are emerging as viable, real-world solutions (see Fig. 1). “Technology could free farmers up a lot and allow them to focus more on farming, and less on labor scarcity.”

John Deere recently unveiled its first commercially available autonomous tractor following several years of research and prototype designs. It can be operated in part via a smartphone app (see Fig. 2), and according to Pell, “it’s a real game-changer for farmers.”Development of the new machine—the Deere 8R—began with an existing, standard John Deere tractor that Pell and his team essentially reinvented. Called the 3R, when it was first created, it was the most automated and sophisticated tractor the company produced. It is capable of steering by itself, allowing users to be almost hands-off while operating it.

“We were building on top of something that was already mature and really functional,” Pell says.

The new tractor includes NVIDIA Jetson modules—embedded computing platforms that can run multiple neural networks simultaneously for applications including image classification and object detection. They are each equipped with several stereo cameras, which work like human eyes, allowing better depth perception for a 360° view around the tractor.

During several years, the tractor’s developers conducted in-field testing and collected more than 50 million images. Machine learning was part of the mix, enabling the recognition of hundreds of thousands of images—each pixel in every image can be classified in about 100 ms. The new tractor also uses a GPS receiver, complete with sensors and computer vision for extreme accuracy while in the field (see Fig. 3).The stereo cameras can also detect anomalies in the field.

“The driver can just drive and drive and drive, but when it detects an anomaly, the tractor stops, so the driver can deal with the issue,” Pell says.

Currently, the 8R tractor is dedicated to fall tillage, the process of turning over the soil done after peak growing season to reincorporate residue. “It’s the stubble from last year’s crops including branches, leaves, and other things farmers don’t actually harvest,” he says. “They go back into the ground. Turning over the soil reincorporates that organic material and their nutrients back into the fields.” This tractor can prepare several hundred acres of soil in just 24 hours.

This autonomous tillage function gives farmers back valuable time. “It's the easiest job on the farm because the traditional device you're pulling is not mechanically very complex; unlike a planter, which has humans doing all kinds of highly precise things and has lots of moving parts and sensors,” Pell says. “So comparatively, tilling is a very simple job that can be done autonomously.”

He adds, “We wanted farmers to get out of the cab to do other things with their time. We wanted to help get them out of the practice of just going back and forth in a tractor in a field for 14 hours a day. This basically frees up the farmer to do higher-skill tasks.”

Other farming equipment tout similar machine-driven properties such as GPS and other auto-navigation systems. Some offer auto-steering and auto-guidance systems, using photonics and optics technologies.

Anello Photonics (Santa Clara, CA) is developing new technology—a silicon photonic optical gyroscope (SiPhOG)—to support these systems within the agriculture space (see Fig. 4). Optical gyroscopes are the gold standard for precision navigation, explains Mike Horton, CTO of Anello. Used particularly for commercial aircraft, existing optical gyroscopes are very large and expensive.

Anello’s new SiPhOG is on a chip, bringing the technology to a much smaller scale for a wider gamut of applications, from agriculture and trucking to drones and consumer electronics.

This technology comprises a photonic integrated circuit, a silicon nitride waveguide, and silicon photonic chip-scale gyroscope sensor. It is being used for auto-steering and auto-guidance systems for tractors. According to Horton, such systems must maintain accurate positioning—within 2 to 5 cm of its current spot in the field—under a wide range of operating conditions, including in relation to weather. The SiPhOG-on-chip accomplishes that accuracy.

“It makes auto-steering and auto-guidance systems roughly 100 times better than standard GPS systems,” Horton says. “Weather effects are a big problem, and a good gyroscope is needed to both stably steer the tractor and mitigate weather perturbations in the GPS/GNSS signals.”

He anticipates that ultimately, auto-steering and auto-guidance systems will be fully autonomous. “All the major brands and several startups are working on fully autonomous machines,” says Horton. “They will help increase production significantly.”

Other technologies on the market include a driver-optional, fully electric smart tractor, developed by Monarch Tractor (Livermore, CA). They unveiled the machinery in 2020, addressing challenges today’s farmers are facing—climate change, inflation, sustainability efforts, and labor shortages among them. Monarch combines electrification, automation, machine learning, and data analysis to boost productivity and safety, and maximize yields.

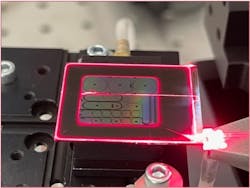

Spain’s Higher Council for Scientific Research (CSIC) developed laser-based machinery as part of a project funded by the European Union. The WeLaser is an autonomous vehicle or robot featuring an AI vision system that can distinguish weeds from crops in a field. Specifically, it detects tissues of the weeds responsible for their growth; a high-power laser then targets and eradicates them. This has historically been done using pesticides, which can be harmful to soil as well as beneficial organisms within it. The WeLaser eliminates the need for such chemicals, ultimately boosting natural sustainability.

Technology for sustainability

“The advances in technology and innovation that we’re seeing really increased agriculture’s ability to do more with less,” says Shelby Myers, an economist with the American Farm Bureau Federation. “For every one single input, natural resources, that agriculture uses, it is outputting about 2.75 times out.”

While the advanced technology is certainly making farming practices more efficient, costs remain an issue. The ability to adopt these technologies depends on the farmer’s ability to pay for them. To boost a farm’s sustainability, Myers says the agribusiness sector will need to develop technology they can get down to a level that allows wider, more widespread adoption, at a price point to incentivize it.

Drones, GPS, and autonomous machinery are particularly helpful for sustainability efforts.

William Osnato, a senior research analyst at Gro-Intelligence (a platform that merges interconnected data with machine learning to study impacts of Earth’s ecosystem), says strong sustainability could come down to a farm’s yield compared to operating costs. The prices of fertilizer and fuel are very high right now, which “motivate people to change practices; for example, turning to advanced technologies.”

Drones are helping farmers make their operations more efficient while also cutting costs. They are commonly used for field mapping. This allows farmers to pinpoint where crops are growing best, which helps the drone target spots for specific disbursement of fertilizers, herbicides, and fungicide sprays, as well as seeds and desiccants. They can also be used to optimize field management, improve grow cycles and boost crop health, and increase yield, all while using fewer resources.

“Being able to identify, isolate, and target those exact areas in a field—that precision farming—provides crucial cost savings,” Osnato says.

Sustainable agriculture is also relying on the next generation of farmers. Osnato notes that as younger people are beginning to take the reins from the aging population of traditional, old school farmers, implementation and use of advanced technology will become more commonplace.

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.