Laser Doppler vibrometry helps make microphone calibration more accurate

Researchers at the National Institute of Standards and Technology (NIST; Gaithersburg, MD) have demonstrated a faster and more accurate way to calibrate certain kinds of microphones. The technique, called laser Doppler vibrometry, uses lasers to measure the velocity at which a microphone’s diaphragm vibrates, and performs well enough to overtake one of the main calibration methods used at NIST and throughout industry.

Someday, the method could be commercialized to become a completely new way to do extremely sensitive, low-uncertainty calibrations of microphones in the field, in places such as factories and power plants. Potential users of such a commercial system could include organizations that monitor workplace or community noise levels or the condition of machinery via sound.

Traditional “comparison calibrations” involve comparing a customer’s microphone to a laboratory standard microphone that has already been calibrated by other means. The laser Doppler vibrometry method demonstrated by NIST has lower uncertainties and is roughly 30% faster than the traditional comparison method currently used at NIST to calibrate customers’ microphones.

To calibrate a microphone, researchers need to measure how sensitive it is to pressure waves. They start by calibrating a set of laboratory standard microphones using a technique called the “reciprocity method”—the gold standard for microphone calibrations.

In a reciprocity calibration, two microphones are connected to each other via a small hollow cylinder called an acoustic coupler. One microphone produces a sound that the other microphone picks up. After a measurement has been taken, the microphones’ functional positions can be swapped, with the transmitter acting as receiver and vice versa.

This process is repeated several times using a total of three laboratory standard microphones. By exchanging the microphones’ roles between measurements, researchers can be sure of the sensitivity of each of the three microphones without the need for a previously calibrated microphone.

Once this master set of microphones has been calibrated, it can be used to directly calibrate customers’ microphones. Different laboratories use different methods to accomplish this goal, but at NIST the technique commonly used for high-accuracy calibration of customers’ microphones is a reciprocity-based “comparison” calibration. It’s called “reciprocity-based” because it uses the same setup as the reciprocity method, except that the newly calibrated microphone acts exclusively as the transmitter and the microphone being calibrated acts exclusively as the receiver.

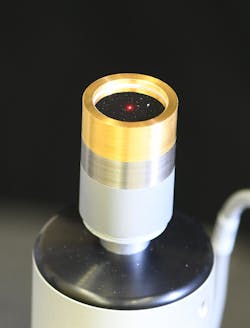

It is this second type of calibration, the “comparison” calibration, that NIST scientists set out to test against the laser Doppler vibrometry method, which measures the physical vibrations of the diaphragm itself. A laser Doppler vibrometer is a commercial instrument that shines a laser beam onto the surface of a microphone whose diaphragm is vibrating at a set frequency. The beam bounces off the surface of the diaphragm and is recombined with a reference laser beam. In this way, subtle shifts in frequency are measured. Researchers convert the signal from the vibrometer into a velocity, which tells them how fast the diaphragm was vibrating at that point on its surface.

To conduct the new test, NIST scientists used nine nominally identical laboratory standard microphones, each with an 18.6-mm-diameter diaphragm. All were tested at two frequencies, 250 Hz and 1000 Hz. They began by measuring over the whole surface area of the diaphragms. They found that the velocity in the center of the diaphragms was significantly higher than near the edges, where there was practically no motion.

Ultimately, they discovered that the best approach was to use data from just a small section at the center of the diaphragms taking up only 3% of the total surface area. The idea of using just the central section came from a recent paper by a team of researchers from the Republic of Korea and Japan.

“The key to making the velocity measurements nice and repeatable is measuring in the center of the diaphragm,” explains NIST scientist Randall Wagner. “As you go further and further toward the edges, our measurements just weren’t very repeatable.”

As a final step, Wagner and fellow NIST scientist Richard Allen compared the microphone sensitivities they measured with the laser-based calibrations to measurements they had previously taken using the gold-standard reciprocity calibrations with the same set of microphones. They found that “the numbers agreed very well,” Wagner said. “They were statistically indistinguishable from each other.”

And, while the gold-standard reciprocity method has the lowest uncertainty at 0.03 dB, and the traditional reciprocity-based comparison method has an uncertainty of 0.08 dB, the laser-based comparison method has an uncertainty of just 0.05 dB.

Wagner and Allen say that the laser comparison method saves “significant time” primarily because it is performed in open air. In contrast, the traditional NIST way of doing a comparison at higher frequencies requires connecting two microphones with an acoustic coupler and then filling the coupler with hydrogen, which takes up to 20 minutes per test.

Wagner hopes that scientists will find a way to develop the laser-based system into a highly accurate primary calibration method that rivals or even outperforms the gold-standard reciprocity method. If successful, a primary laser-based method would be significantly faster, since the reciprocity method requires researchers to repeat the measurements multiple times with different combinations of microphones and acoustic couplers.

In the coming months, he and Allen will be upgrading to a more sensitive laser Doppler vibrometer system and will begin expanding the types of microphones calibrated as well as the range of frequencies. They have applied for a provisional patent, and they will also try to turn the method into a suitable primary calibration technique.

Full details of the work appear in JASA Express Letters.