Spectrum of x-rays generated from peeling tape accurately measured for the first time

The production of x-rays through triboluminescence (which is a mechanical process that involves rubbing, breaking, peeling, or deforming a material) can be used as a source for x-ray spectrometry. In fact, a startup company called Tribogenics (Los Angeles, CA) tried to commercialize the technology as a source for materials analysis, although the company eventually folded. But the phenomenon is interesting in its own right: one can take a piece of Scotch tape and peel it from a surface to generate a small amount of x-rays (many online videos exist that give instructions on how to reproduce this effect). When produced by peeling tape, the x-rays are in the form of numerous pulses of about 10 ns duration. The x-ray spectrum resulting from peeled tape has been accurately measured for the first time, according to the researchers at Universidad Nacional Autónoma de México (Mexico City, Mexico) who have made the measurements.

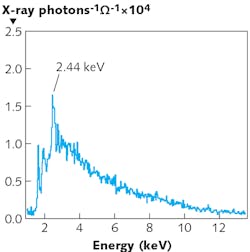

Previous measurements had been susceptible to so-called “pileup,” in which many x-ray pulses overlap in time, causing multiple pulses to appear to solid-state detectors as if they were a single pulse of greater energy. The new measurements, which were carried out in a partial vacuum, were made more accurate by using pinholes to greatly reduce the solid angle subtended by the detector to 5 × 10-6 (with the solid angle Ω defined as Ω = A/r2, where A is the exposed area of the detector’s window and r the distance to the source). The result was a drastic reduction in multiple pulses arriving at the same time. The spectrum showed a peak at 2.44 keV and a maximum photon energy of about 30 keV. For an assumed isotropic emission, the integrated average power of the radiation source was 18.5 nW. Reference: M. C. Hernández-Hernández and J. V. Escobar, Appl. Phys. Lett. (2019); https://doi.org/10.1063/1.5129277.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.