OKI uses D-Wave quantum computer to increase manufacturing productivity

OKI (Tokyo, Japan) and OKI Data (the OKI Group printer company) have applied a quantum computer provided by D-Wave (Vancouver, BC, Canada) to calculate optimal layouts for semiconductor manufacturing machines at OKI Data’s LED Management Factory, successfully obtaining results indicating that the distances traveled by workers can be reduced by an average of 28%.

Quantum computers hold significant promise for dramatically increased computational power compared to conventional computers. Related development work is currently underway worldwide. In Japan, quantum technologies are regarded as important fundamental technologies, on which advances are being made in research and development on a national scale.

While development continues, D-Wave achieved a world first in 2014 by launching a commercial remote access service based on quantum computers known as quantum annealers--specifically tailored to solve combinatorial optimization problems. OKI is involved in research and development on related practical technologies, based on the conviction that the usefulness of quantum computer technologies will be widely recognized and play an integral role in society in the not-too-distant future. At OKI Data’s LED Management Factory, OKI tackled the task of machine layout optimization to validate the basic computing technologies required to solve real-world issues, which OKI had established in these efforts, by applying these technologies in in-house case studies.

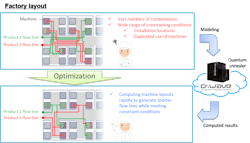

As the working population in Japan shrinks, labor shortages are becoming an increasingly serious issue in manufacturing industries. Improving productivity at manufacturing sites has become a major and pressing social issue directly affecting manufacturing costs. At the LED Management Factory operated by OKI Data, multiple products are manufactured with different manufacturing processes using tens--or even hundreds--of different semiconductor manufacturing machines, with workers constantly moving between machines. Improving productivity here requires optimizing machine layouts to minimize distances traveled by workers (“flow lines”). However, as the numbers of machines and different types increase, the number of possible combinations increases exponentially. In the case examined here, this easily exceeds a googol (10 raised to the power of 100). Due to the need to account as well for complex constraints, including machine installation locations and methods of selecting duplicate machines, it was unfeasible to determine optimal machine layouts by calculating all of these parameters--even using a super computer or other high-performance conventional computer.

OKI and OKI Data used a quantum annealer provided by D-Wave to tackle this layout optimization. From a research perspective, a quantum annealer offers the advantage of facilitating quantitative observations of the results of the optimum layouts computed. However, to solve the problem in an efficient way, a new algorithm suited to constraints involving both the quantum annealer and the manufacturing site was required, making the involvement of personnel familiar with the manufacturing site absolutely essential.

For this reason, personnel from the LED Management Factory were involved in the process to successfully design a computational algorithm in-house by modeling the conditions that apply when manufacturing two types of products involving different manufacturing processes and production quantities within the same factory. A quantum annealer was used to determine optimal machine layouts based on this new algorithm. The end result indicated that flow lines can be reduced by an average of 28% compared to existing machine layouts. OKI and OKI Data plan to refine these results to further increase productivity at the LED Management Factory.

SOURCE: D-Wave; https://www.dwavesys.com/media-coverage/oki-and-oki-data-use-quantum-computer-solve-real-world-optimization-problems

********

Do you have more photonics-related news to share with us? Contact Gail Overton, Senior Editor, Laser Focus World

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.