QCL-based spectroscopy challenges metrological standards for breath alcohol testing

Because calibration methods for breath alcohol measurement instrumentation, including dry standards and wet bath simulators, can produce measurement errors as large as 2%, there is a need for metrological procedures to precisely compare the available reference methods and improve measurement accuracy. Furthermore, dry standards may lead to inaccurate results, as they provide alcohol (ethanol) values without the presence of water and carbon dioxide (CO2)—two molecules that exist at very high concentrations in exhaled breath.

Recognizing these metrological deficiencies, Swiss researchers at Empa (Dübendorf, Switzerland) and METAS (Köniz, Switzerland), the Swiss Federal Institute of Metrology, are using quantum-cascade laser (QCL) sources in a mid-infrared (mid-IR) absorption spectroscopy instrument that can easily provide the missing link between currently established reference procedures/methods.1

High-precision QCLs

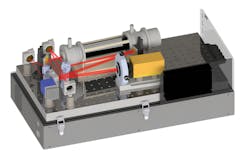

To span the ethanol, water, and CO2 molecular absorption peaks for optimized absorption spectra measurements, a QCL with a wavelength of 9.3 µm was selected and is placed on a translation stage, shaped by a zinc-selenide lens, and fed into a multipass reference cell with a 25 m optical path length (see figure). Wavelength tuning is accomplished by modulating the laser current and the output is analyzed by a thermoelectrically cooled mercury cadmium tellurium (MCT) detector. The entire setup is housed in a compact and rugged system, including the electronics and user interface to allow for mobile measurements.

The device has an inherently high temporal resolution of <1 s, kilohertz scanning speeds, and high coherence and brightness of the QCL source, resulting in an outstanding signal-to-noise ratio. As a result, Lambert-Beer’s law dictates a strong and highly selective absorption signal compared to nondispersive infrared (NDIR) technology that is typically used for commercial breath alcohol analyzers. By operating the QCL in intermittent continuous-wave (iCW) mode, the spectral coverage is extended to span the large spectral range of water and other larger molecules.

Measurements of 30 ppm ethanol in the presence of up to 5% CO2 resulted in a root-mean-square (RMS) error of about 14 ppb after 1 s integration time and settled in at around 9 ppb after 60 s. This precision is maintained in the presence of water and allows the QCL-based instrument to act as a highly efficient tool to elucidate and eliminate the differences obtained in today’s methods for the production of ethanol references gas mixtures.

“This is a milestone in selectivity and precision that can be obtained for the analysis of organic molecules using QCLs,” says Lukas Emmenegger, head of the Empa Laboratory. “It creates tantalizing options for a wide range of applications that go well beyond the quantification of breath alcohol in challenging gas mixtures.”

REFERENCE

1. O. Aseev et al., Opt. Express, 27, 4, 5314–5325 (2019).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.