Top considerations when designing an optical product for manufacturability

Not all great ideas are destined to make it from the napkin to production. That’s because often, there are aspects of a design that make it too difficult or resource-heavy to manufacture and still make a profit. Designing a product for manufacturability means that it can be built within budget, and virtual prototyping tools are the most efficient method to determine whether a product idea will be manufacturable. Here are some of the top considerations when designing an optical product for manufacturability.

Desensitize the design

When designing for manufacturability, it’s important to desensitize the design, and understand how a loose tolerance or misaligned lens can impact the optical performance. The cost of fabrication can increase significantly as tolerances are tightened, but most optical systems can tolerate a certain amount of deviation from the ideal design. Optical design software has a variety of tools that can help engineers reduce the cost and increase the manufacturing yield of their optical products. For example, the Monte Carlo tolerance analysis in Zemax OpticStudio can simulate the impact of all the tolerances simultaneously. The design can also contain multiple configurations that represent the best- and worst-case alignment scenarios, which can all be optimized at once to automatically desensitize the system. These configurations can account for variations in laser specifications, or for different environmental factors like temperature and pressure.

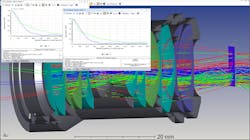

Conduct a full ray trace

To accurately assess manufacturability and predict the optical performance of a design, it’s important to trace both sequential and non-sequential rays through the optical system. Software can simulate the effects of stray light and scattering from lens edges or mechanical components, ensure out-of-field rejection to prevent flare, or simulate the system performance with an imperfect or real source. These analyses can be computationally intensive, so it is important to look for software that focuses on performance and includes features that support productivity. For example, OpticStudio offers LightningTrace, which allows designers to accelerate conventional non-sequential ray tracing by orders of magnitude, modifying system parameters with real-time results and quickly optimizing and tolerancing systems.

Use virtual prototyping to get to a high-confidence design

Most optical software packages simulate the performance of the optics in isolation, but this isn’t a comprehensive representation of how the optical components will be assessed once the product is manufactured. Instead of simulating the lenses or other optical components floating in an ideal space, a virtual prototype also includes the mechanical housing to realistically analyze the out-of-field rejection, whether enough stray light is blocked, or whether any of the mechanical components are contributing to stray light and potentially clipping the beam. This is a critical step in designing for manufacturability.

For example, Zemax Virtual Prototyping bridges the divide between optical design and mechanical design. In fact, it’s the only solution that creates a working virtual prototype of the entire optomechanical product—not just the optical or mechanical components alone. Using LensMechanix for mechanical design in concert with OpticStudio for optical design allows engineers to reliably design for manufacturability. LensMechanix brings the power of OpticStudio ray tracing straight to the mechanical CAD package so that mechanical, product, and systems engineers can ensure the quality of the optical performance throughout the entire design cycle.

Watch the latest on-demand webinar from Zemax to learn how to design for manufacturability using Zemax software. Learn how to desensitize your design, tolerance systems with custom alignment procedures, incorporate as-built performance, add mechanical components, and produce a high-confidence design.