Everything You Need to Know About Aspheric Lenses

Getting Started: Benefits of an Aspheric Lens

Spherical Aberration Correction

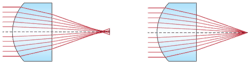

The most notable benefit of aspheric lenses is their ability to correct for spherical aberration. Spherical aberration results from using a spherical surface to focus or collimate light. In other words, all spherical surfaces suffer from spherical aberration independent of alignment or manufacturing errors; therefore, a non-spherical, or aspheric surface, is needed to correct for it. By adjusting the conic constant and aspheric coefficients, an aspheric lens can be optimized to minimize aberration. For example, consider Figure 1 which shows a spherical lens with significant spherical aberration compared to an aspheric lens with practically no spherical aberration. In a spherical lens, spherical aberration causes incident light rays to focus at different points, creating a blur; in an aspheric lens, light focuses to a point, creating comparatively no blur and improving image quality.

To get a better idea of the difference in focusing performance between an aspheric lens and a spherical lens, consider a quantitative example of two comparable lenses with 25mm diameters and 25mm focal lengths (f/1 lenses). The following table compares the spot size, or blur size, of on-axis (0° object angle) and off-axis (0.5° and 1.0° object angles) collimated, monochromatic light rays of 587.6nm. The spot sizes from the asphere are several orders of magnitude less than those of a spherical lens.

Figure 1: Spherical Aberration (left) in a Spherical Lens Compared to No Aberration in an Aspheric Lens (right)

Object Angle (°) | 0.0 | 0.5 | 1.0 |

Spherical Spot Size (μm) | 710.01 | 710.96 | 713.84 |

Aspheric Spot Size (μm) | 1.43 | 3.91 | 8.11 |

Additional Performance Benefits

Although various techniques exist to correct aberrations caused by spherical surfaces, none match the imaging performance and flexibility that aspheric lenses provide. Another technique used includes increasing the f/# by “stopping down” the lens. Although this approach can increase image quality, it also reduces the amount of light throughput in the system, thereby leading to a tradeoff between the two.

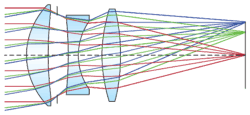

On the other hand, when using aspheric lenses, additional aberration correction makes it possible to design high throughput (low f/#, high numerical aperture) systems while simultaneously maintaining good image quality. Consider an 81.5mm focal length, f/2 triplet lens (Figure 2) consisting of all spherical surfaces versus the same triplet with an aspheric first surface where both designs use the same glass types, effective focal length, field of view, f/#, and total system length. The following table quantitatively compares modulation transfer function (MTF) @ 20% contrast of on-axis and off-axis collimated, polychromatic light rays at 486.1nm, 587.6nm, and 656.3nm. The triplet lens with the aspheric surface shows increased imaging performance at all field angles, indicated by high tangential and sagittal resolution values, by factors as high as four compared to the triplet with only spherical surfaces.

Figure 2: Polychromatic Light Through a Triplet Lens

Object Angle (°) | 0.0 | 0.5 | 1.0 |

Spherical Spot Size (μm) | 710.01 | 710.96 | 713.84 |

Aspheric Spot Size (μm) | 1.43 | 3.91 | 8.11 |

System Advantages

Aspheric lenses allow optical designers to correct aberrations using fewer elements than conventional spherical optics because the former gives them more aberration correction than multiple surfaces of the latter. For example, in zoom lenses where ten or more lens elements are typically used, one or two aspheric lenses can be substituted for a handful of spherical lenses in order to achieve similar or better optical results, minimize the overall cost of production, as well as reduce system size.

An optical system with more elements can negatively affect both optical and mechanical parameters, contributing to tighter mechanical tolerances, additional alignment procedures, and increased anti-reflection coating requirements. All of these may ultimately decrease total system utility because of the necessity for increased support components. As a result, incorporating aspheric lenses (though higher priced than similar f/# singlet and doublet lenses) can actually reduce overall system design costs.

Click here download a PDF of this article!

About Sponsor

Edmund Optics is a leading supplier of optics and optical components, designing and manufacturing a wide array of multi-element lenses, lens coatings, imaging systems, and opto-mechanical equipment. EO’s state of the art manufacturing capabilities combined with its global distribution network has earned it the position of the world’s largest supplier of off-the-shelf optical components. Customers can purchase items by calling 1-800-363-1992, via the catalog or the website at http://www.edmundoptics.com/