Optically Pumped Semiconductor Laser Advantages: Wavelength Flexibility without Compromise

The Optically Pumped Semiconductor Laser (OPSL) technology offers numerous advantages over other types of CW lasers, including wavelength flexibility. In particular, an OPSL can be designed to match the wavelength requirements of the application, which represents a paradigm shift over legacy technologies. This is a major reason why OPSLs are the lasers of choice in applications across the life sciences, as well as for entertainment/light shows, scientific research, and many other applications.

Gas lasers and diode pumped solid state (DPSS) lasers are limited to specific wavelengths that are inherent to the gain material. Typical examples are argon ion lasers at 488 nm and DPSS lasers at 532. There is no easy option to produce say 498 nm or 542 nm output. Conversely, diode laser technology can be custom designed to produce arbitrary wavelengths over a wide range of the visible and near-IR spectrum. But these edge emitters have optical limitations which affect their spectral brightness and are still limited to very low powers for green, yellow and orange wavelengths for example.

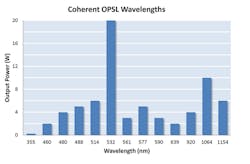

Figure 1. Coherent offers OPSLs at numerous standard wavelengths and produces custom wavelengths for OEMs.

In an OPSL, the gain medium is a semiconductor disk pumped by diode laser(s). The details of the semiconductor can be designed to produce a fixed output wavelength anywhere over a broad range. But unlike laser diodes, this gain chip is based on a surface emitting geometry which delivers a high-quality TEM00 circular output beam. Plus the OPSL architecture provides efficient cooling of the gain chip with no thermal lensing. So OPSL technology is also power scalable: from milliwatts to tens of watts. And just as important, the power of an OPSL can be user adjusted from 10-100% with no impact on beam pointing. This enables easy alignment and setup as well as power optimization for applications like super resolution microscopy where this is a critical need.