Custom Micro-Optic Fiber Assemblies

Key Highlights

- Gooch & Housego offers end-to-end manufacturing of custom micro-optic fiber assemblies, ensuring high quality, reliability, and scalability for real-world applications.

- Their solutions integrate free-space optics, fiber coupling, and electronic components within ruggedized, hermetically sealed packages tailored for harsh environments.

- Applications span defense laser systems, industrial laser control, and advanced biomedical imaging, showcasing the versatility of micro-optic assemblies.

- The company's expertise in materials science, optical design, and precision manufacturing reduces development risk and accelerates deployment of complex photonic systems.

- Vertical integration allows G&H to maintain tight tolerances, optimize performance, and support volume production for long-term operational needs.

As photonic systems become smaller, more integrated, and more performance-critical, competitive advantage is increasingly defined not by individual components, but by the micro-optic fiber assemblies that transform photonic concepts into deployable subsystems. These assemblies must combine optical performance with mechanical stability, manufacturability, and long-term reliability - often in environments where failure is not an option.

At Gooch & Housego (G&H), custom micro-optic fiber assemblies are a core capability. They sit at the intersection of optical physics, precision engineering, and industrial manufacturing - bringing together free-space optics, fiber coupling, photonic devices, detectors, and electronics into compact, ruggedized units designed for real-world deployment.

What differentiates G&H is not only the ability to design these assemblies, but to execute them end-to-end in-house. From crystalline material selection and orientation, through cutting, polishing, and optical coating, to fiber coupling, detector integration, and hermetic packaging, G&H controls the full manufacturing chain. This vertical integration reduces risk, accelerates development, and ensures custom designs can be industrialized reliably at scale.

Three examples illustrate how this capability is applied across defense, industrial, and advanced sensing markets: a Thales laser rangefinder transmitter, Fiber-Q®, and Polarization Diverse Receivers (PDRs).

What defines a custom micro-optic fiber assembly?

Unlike discrete photonic components, a custom micro-optic fiber assembly is:

● Application-specific, not off-the-shelf

● Optically and mechanically integrated, often combining free-space and fiber domains

● Manufactured for reliability, not just laboratory performance

● Designed for volume production, lifecycle support, and harsh environments

In practice, this means tight opto-mechanical tolerances, hermetic or ruggedized packaging, passive or semi-passive alignment strategies, and deep control over materials, coatings, and fiber interfaces. Achieving this level of integration is non-trivial: it requires aligning optical design, materials science, mechanical stability, and production engineering within a single manufacturing environment.

Defense example: Thales laser rangefinder transmitter

For next-generation defense sensors, Thales required a step-change in size, weight, power (SWaP), reliability, and lifetime for laser rangefinders expected to remain in service for more than 20 years in harsh operational environments.

The innovation combined a diode-pumped solid-state laser design with telecoms-style manufacturing processes - an approach that demanded specialist micro-optic packaging expertise to succeed.

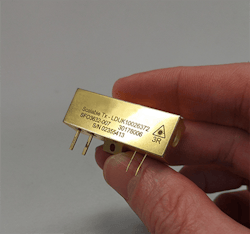

G&H collaborated with Thales to manufacture the laser transmitter as a compact, hermetically sealed micro-optic assembly, translating the patented laser architecture into a deployment-ready subsystem. Leveraging proven telecoms manufacturing techniques - such as precision alignment, low-outgassing materials, and sealed packaging - the transmitter achieved unprecedented compactness, reliability, and lifetime.

First demonstrated through an Innovate UK-funded program in 2015, the resulting assembly is now being rolled out across major UK defense platforms, including Challenger 3 and Boxer - a clear example of custom micro-optic assembly enabling the transition from concept to in-service system.

Industrial and laser systems example: Fiber-Q®

In industrial and scientific laser systems, precise control of timing, intensity, and beam shape is critical. In many architectures, this control is enabled by a fiber-coupled acousto-optic modulator (FCAOM) - but only if it can be integrated without compromising the inherent advantages of fiber-based systems.

In 2009, G&H combined its acousto-optic expertise with micro-optical packaging capability to create Fiber‑Q: a compact, low-loss, robust FCAOM designed specifically for all-fiber laser architectures.

Fiber-Q® is, at its core, a custom micro-optic fiber assembly. It integrates precision acousto-optic crystals, free-space micro-optics, fiber coupling interfaces, and ruggedized, sealed packaging into a single, deployment-ready module. All elements are manufactured under vertically integrated quality control - from crystal growth and orientation through to polishing, coating, and fiber coupling.

The result is a device that delivers low insertion loss, high extinction ratio, and long-term stability across applications ranging from industrial laser machining to aerospace and defense, space, sensing, and quantum technologies.

Critically, Fiber-Q® was designed from the outset to be adaptable. Variants are routinely customized for wavelength, acoustic frequency, polarization handling, environmental sealing, and footprint, demonstrating how custom micro-optic assemblies can be tailored to specific system needs without sacrificing manufacturability or reliability.

Life Sciences and advanced sensing example: Polarization Diverse Receivers (PDR)

In swept-source optical coherence tomography (SS-OCT) and other coherent sensing systems, polarization instability is a major limiter of image quality. Changes in polarization state through the sample arm can lead to polarization fading, signal dropouts, and reduced contrast - particularly in high-speed or long-range imaging applications.

G&H’s Polarization Diverse Receiver (PDR) was developed specifically to address these challenges through a micro-optic architecture, rather than a purely fiber-based approach.

The PDR splits incoming sample and reference signals using a combination of non-polarizing and polarizing beamsplitters, separating the S and P polarization states and detecting each on a pair of balanced photodetectors. This dual balanced detection scheme enables the elimination of polarization fading by recombining polarization channels electronically, even as polarization evolves through the system over time.

Crucially, G&H implements this architecture using free-space micro-optics rather than fiber combiners, avoiding the instability that can arise when reference polarization is not maintained in fiber. The result is a receiver that delivers improved stability, repeatability, and image quality - while also enabling future polarization-sensitive OCT, where changes in polarization carry diagnostic information.

From a performance standpoint, the PDR leverages small-area photodiodes to achieve electrical bandwidths exceeding 1 GHz, supporting large imaging depths and high-speed acquisition. Typical common-mode rejection ratios of ~35 dB further enhance signal fidelity. All optical and electronic elements are integrated into a compact, hermetically sealed micro-optic package, with options for discrete modules or integration with balanced detector PCBs to simplify system integration.

One capability, many markets

Across these examples, the common thread is not the application - but the capability.

G&H designs and manufactures custom micro-optic fiber assemblies that sit at the functional heart of complex photonic systems, controlling performance, reliability, and scalability.

Whether enabling long-life defense laser rangefinders for defense applications, high-power industrial fiber lasers, or advanced OCT detection, these assemblies translate photonic innovation into systems that can be built, deployed, and supported at scale.

As photonics continues to move from laboratory concepts to fielded platforms, the ability to vertically integrate the design, manufacture, and packaging of custom micro-optic fiber assemblies will increasingly define who can deliver - and who cannot. This is where G&H’s depth of integration, manufacturing discipline, and application-led engineering make the difference.