Aveva laser-scanning software captures hydrocarbons facility as-built in 3D for revamp project

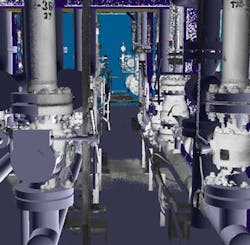

Moscow, Russia--Aveva announced that Burgasnefteproekt (Burgas, Bulgaria), an engineering company in the petrochemicals field, is using Aveva's Laser Modeller, laser-scanning software that captures 3D models of entire rooms and their contents, to achieve significant cost savings. Burgasnefteproekt recently acquired the Aveva software and used it to capture an as-built hydrocarbon flaring system and create a 3D model. This is part of a revamp project to rebuild the system and ensure up-to-date, accurate project documentation. Using 3D laser-scanning technologies and processing the scan data using Aveva Laser Modeller and Aveva's plant-design management system (PDMS), Burgasnefteproekt achieved approximately 80% savings in design man-hours.

The laser scan data captured from the facility was imported into Aveva Laser Modeller; on completion the model was transferred to Aveva PDMS. The result is an accurate 3D as-built model that Burgasnefteproekt used for the revamp project, and will use for future design and maintenance activities. Any future plant modifications can be compared to the as-built 3D model.

“Using Aveva technologies we were able to complete the documentation in only 136 man-hours,” says Rosen Spasov Kutiev, Head of Technical Department, Burgasnefteproekt. “Using traditional ways of working, the same task would have taken us between 700 and 900 man-hours.” The Aveva laser technology is hardware independent, notes Evgeny Fedotov, Senior Vice President Russia, India & Middle East, Aveva; users can opt for virtually any laser scanner hardware and the Aveva laser software will support the import of the collected data.

For more info, see www.aveva.com/Aveva_Laser_Modeller

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.