Inverse design algorithm produces integrated photonic devices automatically from the 'full design space'

A group at Stanford University (Palo Alto, CA) has come up with and demonstrated a new method to design integrated photonic devices; called an inverse design algorithm, the approach "explores the full design space of fabricable devices." The resulting devices, while odd-looking, use diffractive structures to do the optimal job in much smaller spaces than conventional devices.1

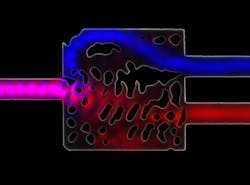

An example (seen above) is a two-wavelength demultiplexer for use at telecommunications wavelengths. The device has only a 2 dB insertion loss, a crosstalk of less than -11 dB, and a bandwidth of greater than 100 nm.

Results look like swiss cheese

Optical interconnects for communications contain many individual integrated photonic devices. Up to now, engineers have had to design optical interconnects one at a time. Given that thousands of such linkages are needed for each electronic system, optical data transport has remained impractical for many uses. In contrast, the Stanford algorithm can design photonic circuits with combined functions.

"We used the algorithm to design a working optical circuit and made several copies in our lab," says Vuckovic. "Our structures look like Swiss cheese but they work better than anything we've seen before."

The group reported in Nature Photonics that the devices functioned flawlessly despite imperfections.

"Our manufacturing processes are not nearly as precise as those at commercial fabrication plants," Piggott says. "The fact that we could build devices this robust on our equipment tells us that this technology will be easy to mass-produce at state-of-the-art facilities."

Many potential uses

The researchers envision many other potential applications for their inverse design algorithm, including high bandwidth optical communications, compact microscopy systems, and ultra-secure quantum communications.

She, her colleague Alexander Piggott, and the rest of their group have made several different types of optical interconnects and they see no limits on what their inverse design algorithm can do.

In their Nature Photonics paper, the Stanford authors note that the automation of large-scale circuit design enabled engineers to create today's sophisticated electronics. By automating the process of designing optical interconnects, they feel that they have set the stage for the next generation of even faster and far more energy-efficient computers that use light rather than electricity for internal data transport.

Source: http://www.eurekalert.org/pub_releases/2015-05/ssoe-sbh052615.php

REFERENCE:

1. Alexander Y. Piggott et al., Nature Photonics (2015); doi: 10.1038/nphoton.2015.69

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.