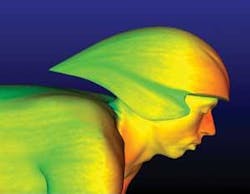

THREE-DIMENSIONAL IMAGING: Laser scanner helps Olympic win

In the sport of track cycling, medals are often decided by time differences of a small fraction of a second. With margins so tight, technology as well as talent plays a role. It is essential to optimize the aerodynamic performance of the bike-and-rider combination. Three-dimensional laser scanners helped hone the performance of the British Olympic team, enabling its members to bring back four medals from the games this summer, including two gold.

The Sports Engineering Research Group (SERG) at the University of Sheffield (Sheffield, England) was funded by a grant from the U.K. Department of Trade and Industry in April 2003 as part of a national program to give the British sports industry access to state-of-the-art R&D facilities. The group bought a facility for digitizing sports equipment and athletes, which became operational last year. The digitizing system, supplied by 3-D Scanners U.K. (Coventry, England) uses the principle of laser-stripe triangulation. A 5-mW solid-state laser is projected in a 70-mm scan line; an angled camera detects shape changes in the line to capture 23,000 points per second. The points are 50 µm apart. The scanner is hand-held, and surface information is captured in a manner similar to spray painting. Using this system, the external surface of an object can be digitized in real time and fed into computer models after a full 3-D surface is created via software.

The rider-bike-helmet combination is digitized separately and then combined into one 3-D model using the software. The model is then fed into a computational fluid-dynamics simulation to study its potential airflow characteristics, as shown here. “We can’t change the rider’s shape,” says David Curtis, technical manager for SERG. “But we can focus on the system as a whole and enhance the equipment and riding position that maintains biomechanic efficiency while optimizing aerodynamic performance.”