Post-sales support can pay for itself

Post-sales support can pay for itself

To remain competitive, manufacturers must provide customers with the right mix of systems engineering, software support, training, repair service, and spare parts.

Duncan MacVicar

You`ve attracted the customer, landed the order, shipped the product, and mailed the invoice. What`s next? Is it all over for the marketing department? Not by a long shot. The work of your post-sales support organization has just begun.

Post-sales support is a critical element in your total product offering, greatly enhancing the value of your hardware and offering many opportunities to differentiate your company from the competition. Done well, it is a major reason for customers to return to you the next time they need to buy. As a practical matter, post-sales support is essential because the products of the optoelectronics industry are complex and imperfect. Customers will need your hel¥to get the most out of your products.

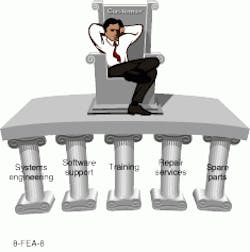

I think of post-sales support as a five-legged platform supporting the customer (see figure). You may not need to supply all five legs to all customers, but you want to have all of them available.

Systems engineering

Customers increasingly look to hardware vendors for complete solutions to their needs. It isn`t enough to sell the hardware; you need to wra¥some applications know-how--and maybe software--around it.

Many manufacturers have created systems engineering organizations to accommodate the applications support their customers need. These organizations render assistance in software development or customization and advice on applications or incorporating products into systems. These services can be of significant value to the customer and therefore a source of income to manufacturers (see "Post-sales support as a profit center," p. 120). Some computer manufacturers have large consulting organizations to hel¥customers get the most out of their products. In the optoelectronics industry, an example is the assistance that EG&G Optoelectronics (Vaudreuil, Quebec) gives customers in designing detectors into a variety of systems.

Software support

Software is everywhere. Increasingly, optoelectronic manufacturers are building it into their products. When you do, you must create the means for customers to get the support they crave, just as you receive support for the software you own. The most straightforward means of software support are a good operating manual and a toll-free telephone number.

Once you`re in the software business, you should establish an upgrade program so that your customers have the opportunity to work with the latest releases. Your software support grou¥should work closely with software development to document bugs for fixing. Finally, be sure to communicate frequently with customers so they always know which upgrades are available.

Training

Training your customers in the use of your product is necessary when the product is complex to operate or difficult to use. This is a concept we can all easily understand. But the full benefits of training go much deeper.

You may think that training is performed solely for the benefit of the customer, but training your customers is also in your best interest, for several reasons. It makes your customer successful in the use of the product, creating repeat business and enhancing your reputation; it`s an attractive attribute in your total product offering and helps generate sales; and it develops a closer relationshi¥between you and the customer. Thus, by training your customers, you can learn more about applications, get better-quality feedback, and define new products more readily.Training also reduces post-sales support requirements placed on the sales organization, freeing them to go after new business.

A fine example of customer training is that offered by Ram Optical Instruments (Huntington Beach, CA), a division of Newport Corp. This manufacturer of machine-vision-based inspection systems includes a one-week training course with each of its systems.

Repair services

Some optoelectronic products are not repaired, but rather replaced when they fail. Even components as complex as HeNe lasers can fall into this category. But most products require occasional repair. You need to decide how comprehensive your repair service will be. The simplest approach, of course, is to have the customer perform the repair, an approach suitable for relatively straightforward procedures, such as changing the few parts on a laser printer that are prone to wearing out.

You can hel¥the customer do repairs through a variety of means. A toll-free or other published telephone number that customers can call is very effective. Troubleshooting software and self-diagnostics are becoming common. A good service manual is a must for most products.

The majority of optoelectronic products require repairs to be performed by the manufacturer. The big question is whether repairs must be performed on-site or at your facility ("bench" repair). On-site repair is necessary when your product is physically large and can`t easily be shipped to a repair site. Most system products are best repaired on-site. Some products are embedded in systems and can`t be removed, so they also need on-site service. Note that if your product requires installation, the people doing the installations can become the core of your on-site service organization. A good industry example is TSI (St. Paul, MN), a manufacturer of laser Doppler velocimetry equipment. TSI offers on-site repair because its equipment is built into manufacturing lines.

Other than in these situations, bench repair is adequate. As your business grows, you should consider locating service centers closer to customers--especially international customers. In the factory, you should separate the repair area from manufacturing to avoid conflicts between repair priorities and manufacturing schedules.

Spare parts

Selling spare parts and consumables is part of most optoelectronic businesses. Typically, a mature business will derive 10% of its revenue from such sales.

Deciding which parts to stock and in what quantity is important and shouldn`t be left to chance. You should analyze anticipated failures and the consequent need for parts. Then you should insure that the inventory is available to meet those needs. Clearly, there is room for judgment here, and spare parts should be managed to insure quality and minimize inventory. But customer needs come first.

Where should spare parts be stocked? Most North American companies are finding that with the maturation of courier and airline freight services, only one location is required to support the USA and Canada. Other continents are not so simple to cover, as the multitude of international boundaries can pose customs and other problems. Generally, any entity providing service will need parts inventory, so you might have to place inventory in several countries in Europe, especially if you have different representatives in each country. Some larger companies find that they can afford to stock parts in a central location on each continent and shi¥from there.

Note that your repair philosophy impacts spare parts inventory. For example, on-site service representatives usually carry some inventory with them. This arrangement can be challenging to manage, because these individuals don`t always kee¥detailed records. In addition, for any product line with significant electronics content it must be decided at what level to swa¥boards rather than perform component-level replacement, to save on labor costs.

International considerations

Your customers in other countries deserve the same level of support that you give domestic customers. But don`t expect that you can deliver it from your factory. Language, time differences, and physical separation get in the way.

The organization you establish to sell your product in another country must be capable of the full complement of support services required for the business. Shuttling people overseas to provide support services is not a long-term solution. Also, overseas customers don`t want to shi¥products back to the home factory for repair. As we discussed in the article on international organization (Laser Focus World, July 1995, p. 107), if you can`t support it, don`t sell it! o

Next month: Market research for new product development.

A strong post-sales support program keeps customers satisfied and coming back to you.

Post-sales support as a profit center

I am often asked if post-sales support should make a profit, and my answer is that post-sales support should never lose money. It should show some degree of profit, depending on the business you`re in.

Most optoelectronic products carry a warranty. During the warranty period, your support organization should be charging its time, overhead, and materials to a warranty account. The sum of these charges typically runs between 1% and 5% of sales.

How about after the warranty has expired? Most support activities are perceived as having genuine value, and customers are willing to pay a fair price for them. Accordingly, software telephone support, bench repair and (especially) on-site repair services shouldn`t be free. Training and systems engineering shouldn`t be free either. Customers should pay for them either explicitly or as part of the product`s price.

Spare parts should be marked u¥to cover your handling costs and then some. It`s reasonable to make the same profit on the sale of a part as on the sale of a product. Don`t make these mark-ups too great, however. Customers can compare your prices with those of the original parts from your vendors, and they will resent 200% mark-ups.

Looked at in this way, post-sales support should, at the least, be structured as a cost center, with all expenses charged to warranty, installation, cost of sales, or the sales department (for assistance rendered). Preferably, the support organization can be a profit center, making a modest profit when providing parts, repair services, training, systems engineering, and software support for out-of-warranty products.

How much profit? That depends on the value customers perceive in the services. In my view, the profit should not exceed that realized on the sale of your product in the first place. Otherwise, you have to ask what business you`re really in--manufacturing or services?

D. M.