Computers and Software

Computers and Software

Global optimization advances multivariable thin-film design

Dongguang Li and Burt Nathan

Optical thin films are used in a wide variety of optical components, and a myriad of companies worldwide specialize in film design and manufacture. However, available multivariable software programs for designing the film-layer structure may not provide optimum designs. To our knowledge, all current software programs obtain their final designs either from optimizing a starting guess or by techniques, which may or may not involve a pseudorandom process, that give different answers every time, depending upon the initial conditions.

Next-generation design programs offer true global optimization for thin-film design. A global-optimization algorithm will always find the very best solution possible within the boundary conditions stipulated. The possibility of creating a true global-optimization algorithm for a large number of interdependent variables has been debated for decades. The OpTeFilm software and global-optimization technique developed by Dongguang Li (Edith Cowan University, Australia) gives optical designers a tool to solve multilayer thin-film problems.

Thin-film design overview

An optical film is a multilayer stack consisting of several layers of dielectric materials deposited onto a substrate, each layer having a specified thickness. When an electromagnetic wave strikes the layers in the stack, the phase and amplitude of the wavefront is changed due to each layer`s thickness. The resultant wave can be calculated for both transmitted and reflected waves. In this way, a filter with any arbitrary spectral response can be created, provided one uses enough layers.

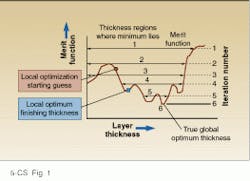

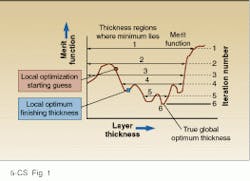

A merit function is used to evaluate how close each design gets to the target requirement. The design process involves finding the design that corresponds to the minimum of the merit function. When plotting the merit function against each layer`s thickness, one axis per layer would be needed, in addition to the orthogonal axis for the merit function.

The merit-function plot would appear as a multipeak, multivariable plot. Because there are many possible interrelated layer combinations, the best film design cannot be found by any simple process. It is not obvious how to adjust the layers analytically to find the best solution. The methods currently used in thin-film design software, such as the damped least squares, simplex, and needle optimizations, all depend on a starting condition that is sometimes not obvious. Changing the initial conditions will give a different result, and the user has no way of knowing how much improvement can be made.

With the global-optimization algorithm embodied in OpTeFilm software, the user knows that the design found is optimized--there is no need to try other starting conditions because there are no starting guesses. This efficiency has powerful economic consequences. For example, previous designs needing excessive numbers of layers can now be fabricated with fewer layers, which lowers cost and gives the same performance and better yields. A manufacturer can improve yields on marginal designs by using a design with a greater margin of error, as well as offering previously unavailable products.

Global optimization

The OpTeFilm global algorithm discovers rather than synthesizes the optimum solution. For example, assume that you plot the merit function against one of the film layer`s thicknesses with a goal of finding the layer thickness corresponding to the minimum merit-function value (see Fig. 1). With local optimization, a fast method for a large number of layers, the program finds the nearest minimum and stops. For some so-called global-optimization programs, the algorithm not only finds a local minimum but can also find some neighboring minima. The process, however, is hit or miss, because starting at a different place can result in different designs.

Our company`s technique repeatedly narrows the region where the global minimum is known to lie by using a special Latin Square algorithm that operates simultaneously in all orthogonal dimensions, one for each layer, to find the optimum design. As the program runs, the user can observe the range of thicknesses for each layer being reduced.

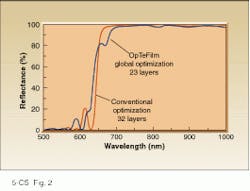

For example, consider a design of an input coupler for a Ti:sapphire laser. This component requires low re flectance at 500 to 550 nm and high reflectance from 700 to 1000 nm. The basic design was optimized by another commercial program to produce a 32-layer design. With our software, which required only the boundary conditions (material refractive indices, substrate, number of layers, and so forth), the resulting thin-film design was obtained in two hours on a standard IBM DX-2 computer operating under Windows. While the characteristics were similar, the OpTeFilm design accomplished these with nine fewer layers (see Fig. 2).

While the thin-film design community is the first to benefit from this method, the mathematical procedures used in OpTeFilm are also applicable to a variety of other unsolved problems related to linked multivariable problems such as image processing and hydraulic flows. n

FIGURE 1. Local-optimization methods locate the minimum closest to the starting point. Global techniques may find other local minima but cannot ensure the absolute lowest has been found. The region investigated by OpTeFilm is progressively narrowed to find a true global minimum.

FIGURE 2. Reflectance characteristics for a Ti:sapphire laser input coupler are similar whether designed by conventional or OpTeFilm programs. However, advanced global-optimization methods accomplish the design with nine fewer layers, lowering fabrication costs.

DONGGUANG LI is a senior researcher at the Faculty of Science, Technology and Engineering, Edith Cowan University, Perth, Western Australia. BURT NATHAN is managing director of Raylight Pty. Ltd., Aldinga, Adelaide, South Australia.