Bulb Library models common light sources

Bulb Library models common light sources

Michael Stevenson

The ASAP Bulb Library (Breault Research Organization; Tucson, AZ) provides a working virtual model of both the photometric and physical presence of common illumination sources (see box). The Bulb Library features a growing set of primarily tungsten halogen sources and will soon include high-intensity-discharge (HID) sources. Bulbs used in the automotive, entertainment, projection-display, and architectural-lighting industries have been characterized.

The library files allow an optical designer to simulate the emissive properties of the filament, the refractive properties of the glass envelope, and the scattering and reflective properties of the glass envelope tip-off, as well as the glass, metal, and plastic parts of the lamp base. For each featured bulb, a complete CAD model has been constructed and imported into ASAP as 30 to 300 entities in a single ready-to-use library file. The use of a predefined source frees the analyst from the task of constructing a source model. Custom models are also made for sources that are not predefined in the Bulb Library.

Building a working source model

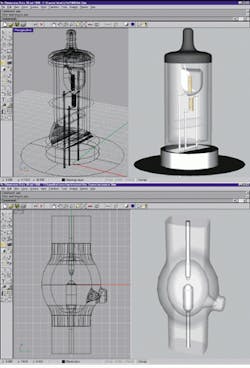

Before a source can be modeled, dimensions for its entire geometry must be determined. This is done through a combination of physical measurement and industry tolerance standards. Once dimensions are known, the Rhinoceros software program is used to form a CAD model. Curves, surfaces, and solids are rotated, blended, and manipulated until they pass as a highly detailed characterization of the source`s geometry (see Fig. 1).

During this process, the model is constructed in object layers. For instance, an arcsource model can have three layers: a layer containing the anode and cathode, an outer glass envelope, and an inner glass envelope layer. The pre-separation of objects allows for speedy assignment of optical properties. The objects in both glass layers will have described interfaces, such as changing refractive indices across surface boundaries, and can be used to consider Fresnel reflections, whereas the metallic objects will be given a reflectivity, roughness, scatter property, or a combination of these.

After a detailed CAD model has been constructed, an IGES export of the geometry is made, and the IGES files are imported into ASAP. Within ASAP, the geometry is faceted and verified using the three-dimensional viewer. Then distinct optical properties are applied to all objects. This method of characterization has been applied to many of the automotive industry`s most popular filament-based sources.

HID arc lamp simulation

Other industries--the projection display industry, for example--require source models that rely on volume emitters. Proper characterization of volume (nonsurface or filament-based) emitters has been troublesome until recently. ASAP incorporates the mathematical theory behind the inverse Abel transform. This transform allows a two-dimensional CCD image to be converted into a three-dimensional emitting volume, which is representational of the true emitting volume. Conventionally, the inverse Abel transform is used to obtain volumes that are rotationally symmetric. Due to the effects of gravity, however, arc sources do not have emitting volumes that are conveniently symmetric 360° about any central or linear axis. Therefore, it is necessary to slice the "banana" shaped CCD image into several thin cylinders that have dissimilar centroids. The inverse Abel transform is applied to each of these smaller cylinders, about a unique axis of rotational symmetry. This technology paired with CAD simulation is the platform upon which virtual arc sources are being created.

Using the source characterization

After a source has been characterized, it can be combined with a source-driven system. The system can be modeled in a CAD program and imported into ASAP, or it can be made solely in ASAP. Regardless, the goal is to simulate the output of the combined source and system. Often, it is valuable to follow the source`s output through the optical system in steps. This approach offers the virtue of finding problem elements and design flaws within the optical system.

In most systems, it is critical to consider the ability of source geometry to impede or perturb rays as they return through the source after hitting the reflector. By including the source`s geometry in the optical system, secondary ray interaction with the source is made possible. This approach allows for an accurate representation of shadows and ghost images presented by systems that send a source`s output back through its origin. In many cases, this type of shadowing and ghosting is a critical factor in determining the structure of whatever lightpipe or reflector is to alter the original path of a source`s output.

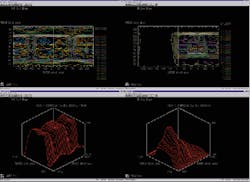

Much like the photometric output of a system can be analyzed, the photometric output of a source is analyzed. Through this evaluation, the analyst verifies the reliability of the working virtual source model. ASAP has several tools ideal for cross-referencing a source`s measured output with its virtual equivalent. A source`s radiant intensity--or axial distribution--can be plotted as a two-dimensional collection of contours or a three-dimensional isometric graph (see Fig. 2). These plots can be compared to the output of a source`s CCD-based characterization. After the virtual simulation is verified, its output can be used as a guide for the creation of optical systems ranging from car headlights to imaging systems. o

Software environment for Bulb Library

The Bulb Library functions in a software environment furnished by the Advanced Systems Analysis Program (ASAP) for illumination analysis and optical design combined with Rhinoceros computer-aided-design software. Rhinoceros and ASAP share a common Initial Graphics Exchange Specification (IGES) format that allows objects characterized in the Rhinoceros 3-D modeling program to be imported into ASAP for analysis. The joining of an optical analysis engine and a three-dimensional graphical design program offers a combination of tools capable of highly accurate geometric and photometric source characterization. It gives engineers like the one shown here and on the cover a tool for visualizing all elements of their system`s optical performance. Moreover, the ASAP/Rhinoceros software environment serves as a method for reducing or even bypassing experimental design and prototyping.

FIGURE 1. CAD system models a 9003/H4 automotive headlamp (top) and an arc source (bottom).

FIGURE 2. Contour plots (top) and isometric plots (bottom) generated by ASAP show high- and low-beam axial output of the H4 headlamp.