Deep learning enables single-shot autofocus in microscopy applications

Before an optical microscope can aid with disease diagnoses, it must first be focused on the sample plane. Acquiring an image that reveals fine features of specimens—such as human tissue samples and cells that feature various details at resolutions less than 1 µm—requires manual focusing by an expert. In clinical laboratories that process hundreds of such samples daily, manual focusing is impractical, especially for rapid imaging of many specimens. Up to now, automated optical microscopy systems have relied on two primary autofocus methods: hardware-based autofocus systems that use additional distance sensors or cameras that are integrated with the microscopy system, or algorithmic autofocusing methods that typically require axial scanning through the sample volume, leading to longer imaging times that can introduce phototoxicity and photobleaching of the sample.

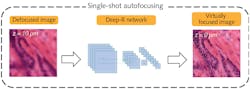

Understanding these limitations, University of California Los Angeles (UCLA) researchers have created a new image autofocusing technique that digitally brings a given microscopy image into focus without the use of a special microscope hardware or equipment during the image-acquisition phase. The team has demonstrated a deep-learning-based autofocusing method that is trained to rapidly and blindly autofocus microscopy images of specimens that are acquired at arbitrary out-of-focus planes. The UCLA team has demonstrated the success of this deep-learning-based autofocusing method on human samples including breast, ovarian, and prostate tissue sections, imaged with fluorescence and brightfield microscopes.

This research, led by Professor Aydogan Ozcan, an associate director of the UCLA California NanoSystems Institute (CNSI) and the Volgenau Chair for Engineering Innovation at the electrical and computer engineering department at UCLA, opens up new opportunities for rapid microscopic imaging of large sample areas, also reducing the photon dose and phototoxicity on the sample.

“When compared with standard autofocusing algorithms, our deep-learning-based blind autofocusing framework enhanced the autofocusing speed of a microscope by fifteenfold, resulting in major time savings, which is especially significant for pathology laboratories that need to rapidly image large numbers of tissue samples,” Ozcan explains. “Simple to implement and purely computational, we believe this patent-pending method will serve the needs of various companies that need high-throughput microscopy solutions.” Reference: Y. Luo et al., ACS Photonics (2021); doi:10.1021/acsphotonics.0c01774.

About the Author

John Lewis

Editor in Chief (2018-2021)

John Lewis served as Editor in Chief of Laser Focus World from August 2018 through October 2021, after having served as the Editor in Chief of Vision Systems Design from 2016 to 2018. He has technical, industry, and journalistic qualifications, with more than 13 years of progressive content development experience working at Cognex Corporation. Prior to Cognex where his articles on machine vision were published in dozens of trade journals, he was a technical editor for Design News, covering automation, machine vision, and other engineering topics, for over six years.