Passive two-phase cooler by Celsia for LEDs and concentrating photovoltaics achieves 1000 W/cm² operation

Celsia (Santa Clara, CA) has developed a form of passive two-phase technology and successfully tested its devices to heat loads of up to 1000 w/cm2. The copper based devices, which are made in form factors down to 2.5 mm thick, are designed for applications using high-power-density laser diodes, power electronics, concentrating photovoltaics, or ultrahigh-brightness LEDs.

The company developed several configurations of a copper based two-phase device with a hybrid wick structure to concentrate liquid flow directly to the heat source and achieve the most favorable results. Testing was conducted using a liquid cold plate attached to the devices, but the spreader performance is applicable to air-cooled designs as well.

"Our goal was to push the performance limits of passive two-phase systems in order to provide design alternatives to thermal engineers needing to cool small heat sources with high power densities," says George Meyer, Celsia's CEO. "Rather than having to migrate to a pumped liquid system, efficient heat spreading using our new designs can extend the limits of air-cooled systems."

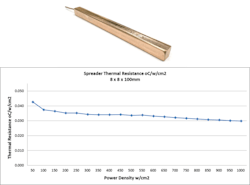

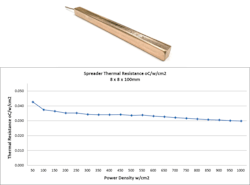

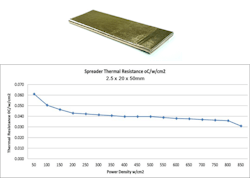

Two platforms with different geometries (see figures below) were tested to 1000 and 850 w/cm2 power levels using a 1 x 8 mm heater that was soldered to the devices. The testing showed stable operation up to the limits of the heat sources. Dry-out power levels for these designs has not been reached yet and the test set is being redesigned to accommodate even higher power densities.

For more information, see http://celsiainc.com/

FIGURE 1. 8 x 8 x 100 mm two-phase device with test results. (Image: Celsia)

FIGURE 2. 2.5 x 20 x 50 mm two-phase device with test results. (Image: Celsia)

Source: Celsia