Tlam laminated thermoelectric coolers challenge ceramics

Most thermoelectric coolers (TECs) use a ceramic-based substrate to electrically isolate and thermally conduct heat. The semiconductor material sandwiched between the ceramic circuit boards pumps heat via the Peltier effect. An alternative drop-in replacement for ceramic substrates called Tlam from Laird (Chesterfield, MO) has comparable cooling for uniform heat loads, better heat spreading in the lateral direction for concentrated heat loads, and improved operational ruggedness with lower substrate costs.

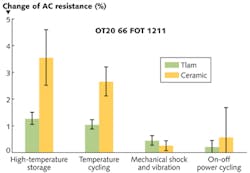

Each Tlam panel uses a thin thermally conductive dielectric layer to electrically isolate the circuit traces from the environment. One side consists of a thin copper foil that can be etched to form circuit traces. The other side is a thick metal backing plate to provide structural support and heat spreading. Unlike ceramics, Tlam substrates can radiate heat from the top, bottom, or lateral direction. The metal backing plates can be made from either aluminum or copper, and several thicknesses of dielectric can be used to suit higher temperature ranges or higher electrical isolation levels. Tlam performed better than ceramic substrates in Telcordia temperature and mechanical stress tests. Tlam also delivered as a scored panel ready to break apart (unlike ceramics that are delivered as discrete components), has 83% greater efficiency than ceramics when cooling concentrated heat loads physically smaller than the Tlam surface area, and produces less strain on the semiconductor than ceramic substrates.

Contact Andrew Dereka at [email protected].