Closed-loop control maintains arc-lamp stability

JACK DONOHUE and NANCY FERNANDES

Other than lasers, short-arc lamps are the brightest manufactured sources of DC (direct-current, or steady-state) radiation, and are used for many spectroscopic applications. The stability of an arc lamp' s output depends greatly on the power supply.

Most arc lamps are constructed with two electrodes separated by a few millimeters and sealed in an oblong quartz bulb. Quartz is used for its mechanical and thermal durability, and its transmissive properties. The bulb is carefully shaped to withstand the thermal gradients and shock inherent in running these lamps.

The bulb is filled with either rare gas at several atmospheres pressure, or a small amount of rare gas and a precisely determined amount of mercury. When the lamps run, the internal pressure can increase to approximately 75 bar, depending upon the lamp type.

Some arc lamps have a third electrode for applying a starting pulse, but this article deals only with the two-electrode type. The two electrodes, called the anode and cathode, are made of tungsten (see Fig. 1). The cathode is small and pointed to ensure that the tip reaches a high temperature for efficient electron emission. The anode is larger to withstand the electron bombardment and efficiently dissipate the heat produced. The small, bright arc is often effectively used as a point source.

Short-arc lamps can be filled with mercury, xenon, or a mixture of both, and range in power from tens to thousands of watts. The output of these lamps is mostly in the UV and visible, which makes them useful for UV spectroscopy and UV photochemistry applications. Mercury-arc lamps emit discrete lines, useful for applications such as photolithography. Xenon-arc lamps produce a continuous spectrum that is a close match to the solar spectrum and can be used for photovoltaic cell testing, cosmetics testing, and accelerated photodegradation studies.

Many applications using short-arc lamps require a stable optical output, both short-term and long-term. Proper design of arc-lamp power supplies, along with closed-loop monitoring and correction of optical output, ensures stability.

Powering an arc lamp

Arc lamps require high-voltage sparks to ignite. After ignition, they need carefully regulated DC for continued operation. An ignitor provides the high-voltage sparks and a power supply provides the regulated current.

The ignitor can be built into the lamp housing, into the power supply, or it can be a stand-alone instrument. If used as a stand-alone instrument, it is important to ensure that the distance between the lamp and ignitor be as short as possible (less than 4 ft) to minimize high-voltage losses due to stray capacitance. For CE-compliant arc-lamp sources, the ignitor is generally built into the lamp housing to ensure that personnel are not exposed to the voltages and currents associated with operating short-arc lamps. Going a step further, all the electronics can be integrated into the illuminator housing.

The stability of the arc-lamp output depends greatly on the power supply. An ideal power supply would not be affected by either variations in the alternating-current (AC) main supply and temperature or interference from the AC mains and other external sources, and would maintain a constant light output. Advances in power-supply technology keep short-term fluctuation in light output below 1% rms (root mean squared). The power supply should also exhibit minimal drift over time.

Operating the lamp

Arc lamps are designed to operate in a specific power range. The manufacturers specify the current and voltage requirements. The power supplies that run arc lamps are usually current sources regulated to maintain either a constant current through the lamp or constant power to the lamp. Many lamp manufacturers recommend that arc lamps be run at a constant current to ensure better lamp stability. Through exhaustive testing, we have found that operating the lamp at constant power ensures better long-term output stability and prolongs lamp life.

There is very little difference in short-term output stability when running an arc lamp with a properly designed power supply in either constant-current or constant-power mode. The differences show up as a lamp ages—even with a stable power source, the radiant output drops because of physical changes (mostly deposits on the inside of the bulb); in addition, the lamp electrodes wear away, changing the electrical characteristics. The increasing distance between the electrodes raises the operating voltage of the lamp.

If the lamp is run at constant current, the electrical power delivered to the lamp will increase as the lamp voltage goes up with age. While this power increase will result in more optical output, in some undefined manner counteracting the loss of light from deposits on the bulb, the increase of power to the lamp will shorten the lamp life and may lead to premature (and sometimes dramatic) lamp failure.

If the lamp is run at constant power, however, the electrical power is kept constant as the lamp ages because the voltage and current are automatically raised and lowered, respectively. Constant-power operation will result in reduced radiant output as the lamp ages, but it will prolong lamp life.

We define lamp life as the average number of hours for the lamp's visible output to fall to 75% of the initial value. If the desire is constant optical power output over the lamp life, even an ideal power supply operating in constant-current or constant-power mode will fall short. It is necessary to adjust the power supply during operation to compensate for the fall in radiant output.

Maintaining long-term output stability

Many factors affect the output stability of an arc source: line-voltage changes, lamp age, electrode erosion, gas adsorption or desorption, and ambient temperature (particularly for mercury lamps). Both the total output and the distribution of power between the spectral lines from a mercury lamp change with temperature. These effects cause output variations with time, with different and sometimes pronounced frequency dependence. In short, lamp output can vary significantly even when the electrical input is held very constant.

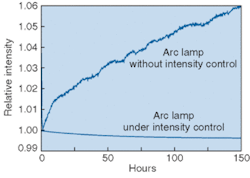

While a highly regulated power supply operating at constant current or power sufficiently maintains a stable lamp output over the short term, long-term (more than six hours or so) stability-critical applications such as photolithography and solar simulation benefit from additional stabilization techniques. In these cases, we recommend the use of a light-intensity control system. Such a system works with the power supply to compensate for lamp-output fluctuations outside the power supply's fundamental control loop, such as ambient temperature changes and lamp aging (see Fig. 2).The principle of operation of the light-intensity control system is simple. A light sensor monitors part of the light-source output, and a controller constantly compares the detector signal to a preset level and changes the power supply output to keep the measured signal at the set level.

Performance benefits of CE marking

Power supplies that are CE-compliant offer significant performance improvements: line-harmonic reduction makes the supplies virtually impervious to line-voltage variation. In addition, more-efficient low-noise-design techniques used to reduce energy escaping from the supplies can also decrease noise inside, resulting in more precise and efficient control.

To make a complete arc-lamp source CE compliant at Spectra-Physics, changes to the arc-lamp housing and cables were required. By enclosing the ignitor in the lamp housing and minimizing and improving the cabling, the radiated and conducted interference—even at ignition—were significantly reduced.

Jack Donohue is electrical-engineering manager and Nancy Fernandes is marketing manager of the Oriel product line at Spectra-Physics, 150 Long Beach Blvd., Stratford, CT 06615; e-mail: [email protected].