Proper capacity control improves chiller performance

ROBERT VANSUMEREN

Recirculating-liquid cooling systems are used in many of today's commercially available lasers to efficiently remove waste heat and avoid overheating of critical components. Although there are numerous heat-transfer fluids used as coolants for a wide variety of laser applications, water is by far the most common coolant used. If the system is properly designed, a recirculating-water system provides an efficient, effective, and reliable means of cooling high-power laser systems.

There are many types of recirculating cooling systems (or chillers) used to circulate fluid. For most laser applications, however, a closed-circuit refrigerated cooling unit is used to maintain proper coolant temperature. The size of the refrigeration system depends upon the heat load produced by the laser when it is operated for long periods of time at its maximum average power. Proper chiller sizing and selection is critical to obtaining optimum laser performance and long-term reliability.

Although there are a many refrigerated recirculating-water chillers on the market, not all water chillers function the same way. Many still use traditional control methods that do not provide for widely varying loads and good temperature stability. To understand the differences in water-chiller technology, it is helpful to first understand why coolant temperature control is important and how, in general terms, it can affect laser operation.

Temperature variation and laser performance

Coolant temperature is a critical factor in the proper operation of solid-state lasers. Because higher temperatures can result in lower laser efficiency, it is generally desirable to operate the system at the lowest temperature practical. If the temperature is reduced to or beyond the atmospheric dew point, however, condensation can begin to form on some laser components that are exposed to the atmosphere.

If the laser-rod ends are cooled to the dew point, for example, condensation can form there; if the system is started, the laser beam can burn off the condensation layer and can damage the surfaces in the process. Solid-state laser systems should never be operated with coolant temperatures low enough to result in condensation. Because the dew point depends on ambient temperature and relative humidity, each application must be analyzed to determine a safe operating temperature based on the conditions the laser is exposed to.

Moisture condensation is also a problem for industrial carbon dioxide lasers, which often have separate or secondary cooling circuits specifically designed to cool the optics. These circuits are usually maintained at higher temperatures than the primary circuit (designed to operate above the ambient dew point).

Coolant temperature stability is also an important factor in chiller design for lasers. Laser-diode devices must be controlled at a specific temperature even with the potential for wide ambient temperature ranges. Failure to control a stable temperature can result in instability of the output wavelength of the laser diode. The output wavelength of a diode typically shifts with operating temperature at a rate of approximately 0.33 nm/°C. In these lasers, the absorption bandwith of the gain medium is normally about 2 to 4 nm, so temperature regulation of the pump diodes to ensure a stable power output from the laser head is essential. Temperature changes in the laser head can result in laser output-power drift, frequency drift in single-frequency operation, and drift in the output beam direction (beam pointing).

Selecting a refrigerated chiller

Several factors should be considered when selecting a water chiller for a laser application. The most important is cooling capacity. Laser manufacturers typically will provide cooling-water specifications that indicate a certain minimum cooling capacity required to properly cool the laser under full-power conditions. It is important to note, however, that lasers do not always operate at their maximum output power. Frequently, lasers are sold to an integrator or end-use customer who may be using the lasers for one of a variety of applications. The laser will often be operated at much less than full time (low duty cycle); as a result, its average output power will be much less than its maximum design output. If the duty cycle falls below 50% of the chiller's cooling capacity, it can lead to control problems. To eliminate control problems, the chiller must provide capacity control over the full cooling range of the chiller.

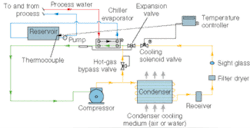

Traditional refrigerated recirculating chiller systems have a fixed "design" cooling capacity. When the chiller is not operating at its full capacity, it is necessary to "offload" the excess capacity to ensure proper operation. If the excess capacity is not reduced, it can prevent system stability and possibly cause damage. To reduce capacity within the refrigeration system, a hot-gas bypass within the refrigeration circuit has traditionally been incorporated (see Fig. 1).

Although there are design variations for hot-gas bypass systems, the goal of reducing system capacity is the same. The hot-gas bypass diverts some of the system's mass flow of refrigerant before it can effectively be used in the condensing and evaporation processes within the system. The hot-gas system is used when the actual process load falls below the design cooling capacity of the chiller. This method for capacity control generally works out satisfactorily until the cooling load falls below approximately 50% of the design capacity of the chiller. At this point, the hot-gas bypass quantity is so large that it can affect the returning gas temperatures for the refrigeration compressor. The refrigeration system's compressor can become heated to levels exceeding the compressor manufacturer's recommendations. Elevated return-gas temperatures cause compressor overheating and can lead to premature compressor failure and shortened life. Consequently, some manufacturers will cycle the compressor on and off when the loads fall below this 50% threshold.

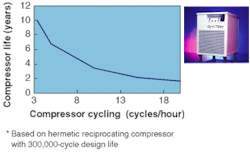

Frequent compressor cycling, however, can cause increased wear and tear on the system, temperature instability, and premature component failures (see Fig. 2). Excessive compressor cycling (or "short cycling") can cause lubrication problems within the refrigeration system. Because a refrigeration compressor is bathed in oil, it will naturally circulate oil throughout the system. Constant cycling can prevent proper oil circulation and cause the compressor to progressively pump oil from the compressor's oil reservoir so that the entire oil charge is lost from the crankcase, starving the components of proper lubrication.A second source of compressor damage can result from liquid refrigerant entering the compressor because of lack of cooling load or improper system design. Methods such as control timers can be incorporated to prevent the system from cycling too frequently. Usually, however, the result is poor system temperature control.

Not every application in which process-water chillers are used without a hot-gas bypass or some other form of capacity control will exhibit stability or process-control problems. For most applications, if care is exercised and the chiller is not grossly oversized, performance is usually satisfactory. There are times that tight system control is required, however. Many times system parameters cannot be determined before the chiller system is specified and purchased. In this case, a chiller that can give not only 50% capacity control but full capacity control is essential.

Advanced refrigeration circuitry

As a result of advances in process chiller controls, portable water chillers are now available that provide zero-to-full-load capacity control. Process water chillers developed at Opti Temp have patented refrigeration circuitry that provides true zero-to-full-load capacity control without cycling the compressor. These chillers also provide temperature stability to ±0.1°C.

Chillers like these offer several advantages, including the ability to operate multiple lasers or processes on one water chiller. The zero-to-full-load capacity control allows one or more lasers to be operated simultaneously or separately as needed without sacrificing temperature control or stability. These chillers can also be equipped with heaters to help bring the process fluid to a temperature above the dew point, minimizing the possibility of condensation. When equipped with a heater, these units will heat or cool actively over a leaving water temperature (LWT) up to 90°C without adverse effects to the compressor or refrigeration system. In addition, the zero-to-full-load control enables these chillers to function as a backup chiller for a variety of process applications.

ROBERT VANSUMEREN is sales and marketing manager at Opti Temp Inc., P.O. Box 5246, Traverse City, MI 49696; e-mail: [email protected].