Clever approach turns multimode sapphire optical fibers into single-mode fiber

Sapphire optical fiber can survive very high temperatures up to 2000°C as well as high radiation. It’s flexible and can be made in lengths up to several meters, so there is potential to use it to monitor extreme environments such as jet engines. Until now, a fundamental problem limited its performance: all sapphire fiber was multimode.

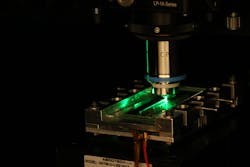

University of Oxford researchers in the U.K. developed a novel concept to transform a multimode sapphire fiber into a single-mode fiber by writing an optical waveguide along its length via femtosecond laser.

A fiber Bragg grating (FBG) is a periodic perturbation of the refractive index along the length of an optical fiber. It reflects light at a wavelength known as the Bragg wavelength, which is based on the pitch of perturbation and effective refractive index of the fiber.

“Parameters such as temperature and strain alter the effective index and pitch, so FBGs can be used as sensors,” says Mohan Wang, a research member in the Department of Engineering Science at the University of Oxford. “And many FBGs can be multiplexed onto a single fiber, each at a different wavelength to enable multipoint sensing.”

Sapphire fiber is grown as a single crystal and typically has a diameter between 60 to 425 µm. Unlike silica fiber, however, there is no core and cladding. Instead, light is guided between the large-diameter sapphire and the surrounding air, with many thousands of optical modes present.

“Since each mode has a different set of effective refractive index, it means each mode has a different Bragg wavelength,” she says. “So sapphire FBGs reflect light over a broad spectrum, and the power distribution in the spectrum will fluctuate with temperature and bending.”

In the new process, when the researchers expose the sapphire to femtosecond laser light it undergoes a reduction in refractive index. “We choose a point in the cross-section to be the core and leave that area alone,” explains Wang. “Then we create a cladding around this core by exposing it to the femtosecond laser to reduce the refractive index, lowering the refractive index around the core. This is known as ‘depressed cladding’ waveguide.”

“We also inscribed an FBG into the waveguide by having a periodic series of rings along the length of the fiber,” she continues. “The resulting single-mode sapphire FBG reflects within a very narrow spectrum (~0.3 nm), which is stable. This means much smaller changes in wavelength can be measured, giving much more accurate sensing.”

One big challenge along the way was to prevent the sapphire from cracking, which took a lot of work to minimize.

As far as applications, the sensors can be used for measurements within extreme environments—such as high temperature and high radiation—of aero engines, nuclear fusion reactors, and space applications. “Being able to make multiple quasi-distributed temperature measurements within an aero engine gas turbine will allow in-flight control systems to optimize performance, reducing emissions and improving efficiency,” says Wang. “This is due to the high temperature capability of >1300°C and the lower system weight compared to existing sensors.”

The researchers demonstrated the sensor on a 1-cm-long fiber, and now plan to extend this length. “We’re just about to do high-temperature testing on some longer devices of a few centimeters,” Wang says. “But eventually we aim to get to several meters in length.”

Now they’re exploring opportunities to instrument an aero-engine test rig with partners Rolls-Royce and Cranfield University. “We’ll supply devices to the U.K. Atomic Energy Authority for evaluation by their Remote Applications in Challenging Environments Division and also to MDA Space and Robotics for them to evaluate for space applications,” she adds.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.