Mode analysis of integrated optical devices for quantum applications

Lithium niobate is a leading material for integrated optics used in quantum and non-quantum optical applications. Due to its nonlinearity, it’s especially valuable when fabricating electro-optical devices for quantum state generation and manipulation. In particular, lithium niobate nonlinear waveguide networks—photonic structures based on the crystalline material—are uniquely suited for quantum state generation. To achieve a squeezed quantum state, a laser is used as the pump to drive a nonlinear parametric process and the laser light generates correlated photon pairs at half of its frequency, where the fluctuation in one quadrature (phase or amplitude) is reduced while the other increases.

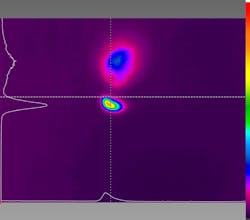

With the interaction of fields at different wavelengths, it’s necessary to know the beam profile of all modes before the development process. In collaboration with Italy’s National Institute for Nuclear Physics (Istituto Nazionale di Fisica Nucleare; INFN), University of Trento researchers are developing integrated optical devices to detect photons and generate squeezed quantum states on-chip (see Fig. 1). One way our team ensures the quality is by using an Ophir laser beam profiler with BeamGage software to characterize the output mode of integrated quantum devices.

Integrated photonics

Similar to microelectronics, which manipulate electrons, integrated photonics combine waveguides, modulators, lasers, and detectors onto a single microchip to manipulate light. This miniaturization is a key driver of quantum technologies and quantum computing. Electro-optic devices based on lithium niobate integrate multiple functionalities on-chip, including nonlinear optical conversion for generating single photons and a squeezed vacuum via parametric down-conversion, as well as amplitude and phase modulation through the electro-optic effect (refractive index changes in response to an applied electric field).

Our team recently developed an integrated circuit within lithium niobate fabricated by using proton exchange technique to generate, manipulate, and measure quantum states of light at a telecom wavelength.

Characterize the output

Waveguides are the core of our newly developed integrated photonics device and fundamental components for photonic quantum computing, a paradigm in which photons are used to encode, transmit, and process quantum information. A waveguide confines and guides light, in modes with a specific intensity profile, along a defined path.

For quantum computing, these waveguides are engineered to support single-photon propagation with minimal loss and noise at a desired wavelength. They are physical structures in materials that channel light within a certain direction. It confines the photons to areas that are of the order of the wavelength of light and enhances the strength of the electric field inside the material.

To ensure the efficiency of the nonlinear interactions, such as the generation of squeezed light, the spatial mode of the pump beam must overlap with the waveguide’s fundamental mode (which has half the frequency). The mode must also overlap with the mode of a standard single-mode optical fiber to ensure the efficient coupling of the photons from the fiber into the waveguides.

During the development phase, we simulate overlap theoretically—but these calculations only provide an estimate of the device’s real mode profile and nonlinear efficiency. The production process of a lithium niobate waveguide requires dedicated knowledge and specialized production facilities. And after the waveguide is produced, it’s essential to check the output mode of the device.

Our team evaluated measurement options by focusing on the boundary conditions imposed by the experimental setup and the nature of the laser emission itself.

Technology selection for reliable laser diagnostics

Selecting the most appropriate technology—one that delivers the necessary, useful, and application-relevant information—requires a comparative evaluation of different measurement protocols and the usability of the resulting data. This includes assessing whether additional optical components are needed to optimize the signal to achieve the highest possible measurement quality.

We evaluated two MKS laser measurement systems for this particular case: 1) A charge-coupled device (CCD) camera with a phosphor-coated sensor, which operates with Ophir BeamGage software, and 2) A rotating slit-system (Ophir NanoScan) with a germanium detector, which operates with NanoScan software.

Both systems are compliant with International Organization for Standardization (ISO)-compatible measurement protocols and offer comparable resolution. These systems can also generate temporal graphs of the measured parameters. The decisive factor in favor of the CCD-based beam profiler with a phosphor-coated sensor was its ability to simultaneously analyze two or more laser emissions within the same measurement area (see Fig. 2). Due to their mechanical setup, a slit-based system cannot offer this functionality in real time.

The strategic advantage of the camera-based solution lies within its large active measurement area, which enables immediate visualization of the laser beam’s cross-section and spatial distribution. Maintaining this information as a benchmark and being able to visualize a second beam—or overlay it retrospectively—allows researchers to reliably detect deviations beyond acceptable limits.

This characterization is important to verify whether our waveguides are single-mode, as well as whether the mode has good overlap with standard optical fibers, and to calculate the overlap with the pump mode to estimate the efficiency of spontaneous down-conversion. The reliability of the measurement solution and its ready-to-use setup convinced us. We selected the camera-based solution by MKS: An Ophir phosphor-coated camera and the Ophir BeamGage software to characterize the output mode of our integrated devices.

This reliability enables us to focus our efforts on the fabrication and optimization of the components under investigation, confident in the accuracy and consistency of the measurement system used for validation. Each data point carries clear significance—without distraction or ambiguity, which is the key to effective laser diagnostics.

The monolithic nature of these devices means that the correct phase can be achieved in a stable manner (in what would otherwise be an unstable interferometer). It greatly simplifies the task of implementing sophisticated photonic quantum circuits.

Beam diagnostics

While the nonlinearity of lithium niobate presents a major advantage for quantum technologies, the material is more challenging to integrate and less robust compared to silicon photonics. This makes it essential to monitor the behavior of the integrated photonic chip for an extended period of time.

Beyond the initial measurements that ensure the quality inspection of a lithium niobate waveguide, the diagnostic part covers the long-term characteristics of the device. We measure the output power of the waveguide on a regular basis, and as soon as the power decreases the mode profile is taken with the Ophir beam profiler to identify any changes of the optical characteristics of the beam.

FURTHER READING

F. Lenzini et al., Sci. Adv., 4, eaat9331 (2018); https://doi.org/10.1126/sciadv.aat9331.

About the Author

Mirko Lobino

Mirko Lobino is an associate professor in the Department of Industrial Engineering at the University of Trento (Italy), where he is developing innovative integrated optical devices for detection of photons and generating squeezing on-chip.

Luca Porcelluzzi

Luca Porcelluzzi is area manager for Ophir Photonics Products at MKS and leads operations within Italy, Switzerland, and Austria. He holds a master’s degree in physics of matter and began his career focusing on microfluid dynamics. His path led him into the world of lasers and optical metrology. With more than a decade of experience within the photonics industry, Porcelluzzi has developed his expertise through roles in sales engineering and marketing management.