New material on the block: Barium titanate for silicon photonics

The requirements and implications of artificial intelligence (AI) are on many people’s minds because these emerging technologies are accelerating the need for faster, more efficient optical interconnects to transfer massive volumes of training and inference data between sprawling data center campuses. As a result, AI applications are pushing operational requirements to new levels and testing the limits of current photonics infrastructure.

For years, lithium niobate (LiNbO3) and electro-optic polymers have been positioned as next-gen modulator technologies—and each offers distinct benefits and drawbacks. But as optical systems push toward terabit-scale speeds, with operators increasingly ramping up bandwidth via the latest 400G and 800G coherent pluggable components, barium titanate (BaTiO3) is emerging as the newcomer to watch within the industry. With a combination of exceptional electro-optic performance and silicon-foundry compatibility, BaTiO3 has the potential to serve as a key enabler for the next generation of photonic devices.

Do more with less to support AI requirements

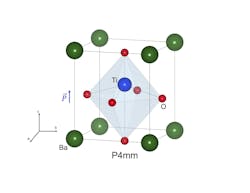

BaTiO3 offers many benefits that make it a standout material platform amid AI’s escalating requirements. It has a unique combination of high nonlinearity and strong electro-optic coupling, with its largest Pockels coefficient reaching up to ~1,300 pm/V, compared to ~35 pm/V for bulk LiNbO3 or ~300 pm/V for leading polymers. This quality makes BaTiO3 more responsive to electrical fields and allows light to be modulated with less voltage, less energy, and a smaller device footprint.

As a ferroelectric with a gigantic Pockels coefficient, it can respond to electric fields quickly while also enabling more compact devices. Combined with a high refractive-index contrast, BaTiO3 enables tight optical confinement, which minimizes loss while maximizing performance. These attributes make it a natural fit for integrated photonic circuits that must pack high-speed and low-power operation into smaller sizes. Ultimately, BaTiO3’s benefits come at a critical inflection point as companies across the optical networking industry strive to decrease cost per bit by lowering the power consumption and footprint of optical devices.

Fostering manufacturing viability

Manufacturing and integration barriers tend to be the most significant obstacles to advancing new optical materials. Silicon still dominates the photonics industry, in which any alternative material must align with existing semiconductor fabrication methods to ensure viability for widespread manufacturing and implementation. Although its manufacturing ecosystem is still maturing, BaTiO3 thin films can now be deposited on silicon wafers—often via radio frequency (RF) magnetron sputtering—to enable scalable growth. This allows manufacturers to achieve the high-volume production necessary for dense telecommunications and data communications links.

When coupling these manufacturing methods with BaTiO3’s enormous Pockels coefficient, BaTiO3 offers greater longevity (>10 years) across generations of innovation, which helps companies secure long-term returns on their investments. These advantages result in a high-performance electro-optic layer fully compatible with standard complementary metal-oxide semiconductor (CMOS) processes, which allows companies to integrate the material into conventional silicon photonics foundry workflows.

LiNbO3 poses contamination risks within silicon fabs and electro-optic polymers are subject to environmental degradation, but BaTiO3 offers durability and performance that means companies can future-proof their solutions. While these quantifiable benefits are established, what real-world applications can BaTiO3 support?

Hyperscalers to healthcare: From the lab to the field

BaTiO3 exhibits wide versatility across various sectors, including hyperscale data centers, optical networking, sensing, defense, and others. As AI and cloud workloads push optical links to their limits, the material’s performance advantages could drive continued speed and efficiency advances. From enabling high-capacity data center interconnects to integrated optical sensors, barium titanate offers unique versatility and is strongly positioned to support a wide range of use cases across the technology ecosystem.

Hyperscale computing and AI data centers. BaTiO3’s most immediate business opportunity is within the hyperscale and AI data center market, as buildouts accelerate and emerging applications strain optical interconnects. Amid these demands, traditional interconnects struggle to keep pace with the bandwidth and energy requirements of AI model training and the distribution of inference responses to end users. Comparatively, BaTiO3-based electro-optic modulators enable ultralow-voltage, high-speed optical links between chips, racks, and data center campuses. These devices can significantly reduce power consumption and mitigate the “AI heat crisis” challenge of hyperscalers amid increased data center construction. This market’s growth is well established, with experts estimating that the AI data center market will reach a $933B valuation by 2030.

Optical sensing and biosensing. Beyond enabling connectivity in telecommunications and data communications applications, BaTiO3’s high electric field sensitivity makes it suitable for integrated optical sensing, including biosensing and environmental monitoring. The material’s high permittivity and field response enable precise detection of biological molecules, pathogens, or chemical changes, and shows potential to transform how researchers and clinicians collect and analyze data at the nanoscale. As manufacturing viability accelerates, compact, on-chip BaTiO3 sensors could soon power portable diagnostic devices and real-time chemical analyzers. This market’s growth outlook is strong, and analysts project it will reach $69B by 2032.

Defense and aerospace. Reliability and speed are non-negotiables in defense and aerospace applications, which make this material platform particularly suitable for many use cases within these industries. BaTiO3’s high modulation efficiency and reliability can support compact light detection and ranging (LiDAR) systems, secure optical communications, and electro-optic modulators that maintain operational efficiency within extreme conditions. Its ability to operate across wide temperature ranges without signal degradation gives it a strategic advantage in military photonics and space-based applications. The global aerospace and defense market also holds strong growth potential, and experts estimate it will reach a valuation of $187B by 2030.

Market momentum and scale challenges

BaTiO3’s rise signifies its maturation from lab research to real-world utility, which reflects the industry trend of materials diversification in silicon photonics. Thin-film LiNbO3 has been attracting a lot of attention due to its reliability, but BaTiO3 may emerge as a formidable contender as the ecosystem increasingly prioritizes power efficiency and CMOS integration. The BaTiO3 market is already showing robust growth potential, and researchers estimate it will reach $2.7B by the end of 2025, rising at a compound annual growth rate (CAGR) of 5.3% by 2030.

But the material faces scalability challenges before it can achieve mass deployment. Wafer-scale uniformity and integration yield remain key hurdles; foundry standardization is also critical. These challenges aren’t new to the photonics industry. Just as silicon photonics overcame early yield and coupling issues, BaTiO3 manufacturing and integration are progressing rapidly. Hybrid architectures combining BaTiO3 with silicon show promise for achieving both high modulation efficiency and low loss.

Lighting the path ahead

BaTiO3’s diverse potential extends far beyond any individual use case. By combining an excellent electro-optic coefficient with steadily maturing manufacturing processes, the material offers a path toward fully integrated electro-optic systems that control light and electricity at the speed and efficiency demanded by high-bandwidth applications. As AI, quantum computing, and ultralow-power networking hold the potential to transform the technology ecosystem, BaTiO3 offers a bridge between laboratory innovation and industrial scalability to enable companies to leverage high-performance material platforms that support their evolving photonics demands.

About the Author

Alex Demkov

Alex Demkov, Ph.D., is a cofounder and CEO of La Luce Cristallina (Austin, TX). He is a distinguished figure within the field of materials physics, and was a professor at the University of Texas at Austin. Demkov received his Ph.D. in Physics from Arizona State University. Prior to joining the University of Texas in 2005, he worked in Motorola’s R&D organizations.