LCOS spatial light modulators enable next-gen laser processing

Recent advances in liquid crystal on silicon (LCOS) technology led to the development of spatial light modulators (SLMs) with 1-kW power handling capability, which means they can now be used for high-power laser applications. As a result, LCOS-based SLMs are a new option for laser processing applications like metal processing.

What’s an LCOS-based SLM?

Originally developed as a microdisplay technology for projectors and rear-projection televisions, LCOS technology was adapted for use in SLMs. These devices are widely used for applications involving visible to near-infrared (NIR) light, including optical communications,1 laser processing,2 adaptive optics, optical manipulation,3 and pulse/spectrum shaping.

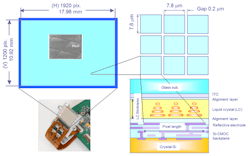

An LCOS device consists of a two-dimensional (2D) matrix of millions of pixels. Each pixel comprises a common transparent electrode made of indium tin oxide (ITO) and a pixel electrode on a complementary metal-oxide semiconductor (CMOS) substrate—which sandwiches a layer of liquid crystal material (see Fig. 1). By independently applying voltage to each pixel, the device can spatially modulate the phase of incident light. Most LCOS devices operate in reflection mode, and each pixel electrode also acts as a mirror.

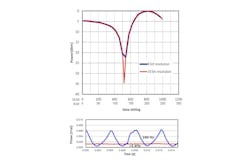

Santec developed an LCOS-based SLM that features a resolution of 1920 × 1200 pixels with an 8.0-μm pixel pitch to support 60- and 120-Hz frame rates. Compared to standard 8-bit displays (256 grayscale levels), our SLM offers high phase resolution with 10-bit (1024 levels) grayscale (see Fig. 2a) and excellent phase stability of <0.002 π radians (see Fig. 2b). This enables precise phase modulation for high-contrast displays and is ideal for phase-critical applications, such as laser processing, optical communications, and adaptive optics.

LCOS devices are driven by AC voltage, which can induce flickering caused by oscillation of liquid crystal molecules. While flicker may be negligible in visual applications, it can severely impact high-precision optical systems. Our SLM reduces flicker by operating at drive frequencies above 1 KHz. It also supports video signal input via a digital visual interface (DVI) and allows phase pattern storage (up to 128 patterns) via universal serial bus (USB) to enable fast switching with external systems using trigger input/output functions. A software development kit (SDK) is available for user-side control via custom programs.

LCOS-based SLM applications

While LCOS-based SLMs are fundamentally phase modulation devices, they have diverse applications—ranging from holographic AR/VR displays to adaptive optics in microscopy and astronomy, and mode conversion in optical communications.

Traditionally, these applications involve relatively low-power lasers. Although LCOS-based SLMs can perform beam shaping for laser processing, their damage threshold had been a limiting factor. But improvements in laser resistance opened the door to their use in high-power laser applications such as metal processing. Unlike conventional systems that require hardware reconfiguration for each task, SLMs enable dynamic, real-time beam shaping—and offer major advantages for precision microfabrication and complex geometry welding/cutting.

Unlocking new frontiers: 1-kW power-handling LCOS-based SLMs

Cutting and welding metal materials typically require lasers with powers exceeding 1 kW. Proper beam shaping can reduce spatter and improve processing quality. To achieve it using an LCOS-based SLM, the device must endure high laser powers. Santec’s SLM-310 offers true 1-kW power handling, which makes it suitable for direct use within demanding laser processing environments.

Optimizing the beam profile during processing enhances thermal efficiency, enables faster cutting, higher-precision welding, and more intricate microfabrication. Complex shapes that were difficult to process before can now be manufactured rapidly and with high precision—and it opens new possibilities for aerospace, automotive, medical, and semiconductor fields.

Advantages of LCOS SLMs with 1-kW power handling

Galvo mirrors are widely used for laser processing to scan the beam by varying angles along x and y axes, but the scanning process is time-consuming. In contrast, LCOS-based SLMs can perform one-shot processing via computer-generated holograms (CGHs)4 to significantly reduce the processing time.

Compared to DLPs, LCOS-based SLMs offer higher phase stability, which makes them better suited for CGH-based processing. Diffractive optical elements (DOEs) can also shape beams, but require physical replacement for different patterns—and this increases the setup time. LCOS-based SLMs allow programmable beam shaping without mechanical adjustments, which enables greater flexibility and efficiency within manufacturing environments.

Evolution of LCOS for NIR laser processing

Conventional LCOS devices, designed for human-viewable displays, were not built to withstand hundreds or thousands of watts of laser power. Exposure to high-power lasers could irreversibly damage various internal components (see Fig. 3), including the cover glass, alignment layer, electrodes, mirrors, and liquid crystals.

To address it, DLPs and galvo mirrors—based on microelectromechanical systems (MEMS) technology—are typically selected for high-power applications. But the LCOS structure within Santec’s SLM-310 is specifically engineered for high damage resistance and features a sapphire cover glass for enhanced thermal conductivity and a high-performance water-cooled heat sink for efficient cooling. An inorganic silicon oxide (SiOx) alignment layer replaces organic polyimide, while dielectric multilayer mirrors made of silicon dioxide (SiO2) and titanium oxide (Ta2O5) minimize light absorption. The liquid crystal material is a blend of low-reactivity fluorinated compounds to ensure thermal and optical stability.

Shaping laser processing’s future with LCOS SLMs

Until now, LCOS-based SLMs were limited to low-power applications such as wafer dicing and laser marking. Our SLM-310 expands these possibilities to include metal processing with multikilowatt lasers—and paves the way for major improvements in processing speed and efficiency.

Traditional beam shapes were static and required setup changes for each new task. LCOS-based SLMs enable real-time, dynamic beam shaping during processing to enable high-precision micromachining of complex patterns, enhanced cutting/welding via asymmetric beams, and multipoint irradiation to improve throughput.

Applications may include high-speed cutting of medium-thickness stainless steel or aluminum, precision machining of aerospace components, and process control in metal 3D printing. The ability to minimize thermal effects also helps prevent material distortion or degradation.

Looking forward, combining LCOS SLMs with artificial intelligence and sensor technologies may enable fully automated systems that can optimize beam patterns in real time based on target conditions. This would accelerate automation and efficiency in manufacturing, and align perfectly with the goals of Industry 4.0.

Combining LCOS-based SLMs and high-power lasers represents more than just an evolution in optical control—it redefines what laser processing can achieve. This quiet revolution promises to reshape the landscape of next-generation manufacturing.

REFERENCES

1. Y. Sakurai et al., IEEE Photon. Technol. Lett., 23, 14, 989–991 (2011).

2. Hotta et al., 77th JSAP Spring Meeting, 14a-C31-2 (2016).

3. Otowa et al., 77th JSAP Spring Meeting, 14p-B3-10 (2016).

4. Y. Hayasaki et al., Appl. Phys. Lett., 87, 031101 (2005).

About the Author

Yuya Suzuki

Yuya Suzuki leads Santec AOC Corp.’s Research & Development Group, Research Team, and is based in Japan.