Space and the battlefield are no place for fragile optics

When NASA’s JunoCam started sending back blurry, faded images in July 2025, the issue wasn’t a broken lens or weak signal. It was years of deep space exposure taking a toll. After more than a decade orbiting Jupiter, the camera’s sensors showed signs of radiation damage, which forced engineers to “bake” the system in hopes of squeezing out a bit more clarity.

Altechna, which manufactures custom optics solutions, recognized it’s not just space optics under strain but also optics operating within harsh environments—where optical coatings must withstand the most extreme conditions.

On modern battlefields, for example, drones equipped with precision optics are flown through dust, salt, freezing temperatures, and constant vibration. Sensors fogging up midflight or coatings wearing down from heat or abrasion can jeopardize the entire mission. Both the space sector and battlefield now share a critical demand: Resilient optics. To ensure survival, every mirror, lens, and window in the optical path must be coated with high-quality coatings resistant to thermal fluctuations, mechanical shock, radiation, and environmental contaminants.

Defense and aerospace optics can face thermal swings from -50° to 150°C, combined with shock, vibration, and airborne contaminants. But it’s not just about survival—coatings must retain high spectral performance and long lifetime stability even as they absorb mechanical and thermal load. This demands precise layer structure, strong adhesion, and materials that can resist degradation over time.

Step one: Test under mission conditions

A recent study by Altechna subjected our magnetron sputtered (MS) coatings to a full suite of space-relevant stressors. To simulate space radiation conditions, we subjected coated samples to proton irradiation (1 × 1011 protons/cm2 at 23 MeV and 68 MeV) and gamma ray exposure (10 to 30 kilorads of the total ionizing dose at 4 kilorads/hour). These levels represented exposure to long-term radiation, which can potentially cause optical scatter, absorption shifts, or structural degradation.

Simultaneously, thermal cycling (see Fig. 1) between -30° and 130°C was used to induce mechanical stress across material interfaces, which exceeded the typical operational envelope to validate robustness under tactical temperature swings.

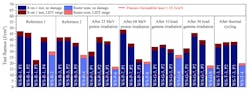

To assess real-world survivability, the coatings underwent laser-induced damage threshold (LIDT) testing at 750 nm (3.5-ns pulses), using both R-on-1 and larger-area raster scanning methods (see Fig. 2). All samples endured fluences at least 1.5x above in-resonator operating levels (~10 J/cm2) with no signs of delamination or performance drop. Transmittance spectroscopy across 500- to 850-nm and tape-lift adhesion tests confirmed spectral stability and coating durability, particularly around the pump (∼636 nm) and lasing (755-nm) wavelengths. Finally, the coated optics were run in a cavity-dumped, Q-switched alexandrite oscillator to validate functional performance under live operation. After 27 million pulses, output energy, beam shape, and spectrum remained within ±10% of baseline, with no observable radiation or thermally induced excess loss.

While designed for spaceborne light detection and ranging (LiDAR) validation, the study demonstrates why such multidimensional test regimes, combining radiation, thermal, and high-repetition laser stress, are essential to qualify coatings for modern defense systems.

Current advances in optical coatings

When coating systems are developed for defense and space, it often begins with one basic question: What will the environment do to this optic?

In the industry, partners are asking for coatings qualified through radiation, thermal, and laser exposure data. We need to show how it performs through testing, prove it with documentation, and align it with real mission parameters, proving that we use the suitable technology. Currently, different types of coatings emerge because of this.

While researchers and manufacturers are constantly designing thin-film coatings that are not only durable but also multifunctional, some of the latest developments are holding the line: Abrasion-resistant coatings, such as hard ceramic films like alumina (Al2O3), silica (SiO2), and hafnia (HfO2), are layered to resist scratches from sand or grit. Some labs enhance these coatings with zirconium oxide to improve erosion resistance while maintaining transparency.

Hydrophobic and oleophobic layers are important for humid or contaminated environments. Fluoropolymer-based or nanotextured coatings repel water and oil, but even bioinspired structures appear. These include moth-eye-like nanopillars that can achieve water contact angles over 135°—more than 2x that of an untreated surface.

Broadband antireflective (AR) stacks are suggested when traditional AR coatings fail under heat due to thermal mismatch. Modern stacks use subwavelength structures or graded-index materials to improve optical transmission and thermal resilience. In one recent case, an AR nanostructure survived 250°C stress tests without optical degradation. While standard dielectric coatings often endure 300° to 500°C, polymer-based AR nanostructures rarely match it.

MS (such as the one in our previously discussed study), ion beam sputtering (IBS), and atomic layer deposition (ALD) are also raising the bar on coating density. These methods virtually eliminate pinholes, minimize water ingress, and prevent delamination—even under vacuum or humidity extremes.

And hybrid multifunction stacks are emerging, because no single coating solves everything. Defense optics increasingly use multilayer stacks that include an abrasion-resistant base, a hydrophobic topcoat, AR, and even antistatic layers in between. Some are topped with ultrathin transparent films to protect nanotextures while preserving their function. Overall, these layered, engineered coatings are becoming the backbone of optics that must endure thermal cycling, shock, sandstorms, and radiation exposure.

Defense spending and laser weapons drive demand for sub-ppm coatings

Demand for sub-ppm coatings from national defense agencies and space programs in the EU between 2021 and 2024 increased the total defense expenditure by more than 30% to reach an estimated €326 billion ($381B) last year.

Projects like TALOS-TWO, the first European sovereign 100-kW high-power laser weapons, are accelerating development of extreme-resistant optics. Such use cases as directed-energy systems require sub-ppm absorption mirrors to avoid heat-induced distortion. While many people think that only IBS-deposited mirrors reach lower than 1 ppm absorption and demonstrate record-high LIDTs, our practice shows that MS can do it even better—and it enables operation at higher power densities without beam degradation.

In missile guidance systems, dichroic mirrors and beamsplitters are now fabricated with IBS or MS to eliminate microscopic voids and improve film density. These improvements translate directly into performance and stability, as well as service life.

Across applications, the trend is clear: Optical systems must now balance ultralow absorption, mechanical robustness, and thermal stability. Sub-ppm coatings, dense dielectric films, and advanced substrates are all converging to help defense optics operate longer and more reliably—without adding weight or bulk. As space missions, high-power laser systems, and autonomous defense platforms scale up, optical coatings are no longer a supporting detail.

About the Author

Deividas Buinovskis

Deividas Buinovskis is the chief technology officer at Altechna and leads its R&D and technology strategy for cutting-edge photonics solutions. With a background in laser technology and applied physics (Magna Cum Laude, Vilnius University), he drives innovation in optical coatings and precision optics for industries from quantum computing to defense.

Laurynas Lukoševičius

Laurynas Lukoševičius received his Ph.D. in materials science from The University of Manchester in 2020. With Altechna since 2019, he’s now chief scientist. His research involves the development of plasma processing and optical coating deposition with a focus on absorption and laser-induced damage threshold of optical components.