Advanced thermoplastics enable microlens arrays for copackaged optics

The rapid expansion of artificial intelligence (AI), the Internet of Things (IoT), 5G networking, and related digital technologies is driving an unprecedented surge in data traffic, which demands faster transmission speeds and greater bandwidth capacity. Traditional electronic interconnects are becoming inadequate, particularly at the data speeds and densities now required. In response, the telecommunications industry is accelerating the development of high-performance, energy-efficient, and sustainable optical data communications systems.

One promising solution is to replace pluggable optical modules with copackaged optics (CPO), which involves placing the optical components on the printed circuit board (PCB) close to, or directly alongside, the application-specific integrated circuit (ASIC) switch or other electronic integrated circuit (IC). By moving the optical-to-electronic data conversion as close as possible to the ASIC switch within data centers, CPO significantly boosts bandwidth and dramatically increases the energy efficiency of data centers.

But moving optical interfaces to the chip or photonic integrated circuits (PICs) creates new challenges. Most critically, any optical component must now withstand the high temperatures of reflow soldering used during PCB assembly, which can reach 260°C. This limits the choice of materials suitable to manufacture these optical elements—particularly, lenses.

Efficiently coupling light into and out of PICs, optical fibers, and sensors has become a cornerstone challenge. One solution is microlens arrays (MLAs), which are comprised of multiple small lenses (lenslets) arranged within a grid on a substrate. They facilitate high-efficiency optical coupling while supporting noncontact, free-space optical interfaces. But reaching their potential at scale requires mass production and assembly of thermally resilient micro-optical components.

Choose the best material for MLAs

Currently, the majority of MLAs are fabricated by etching fused silica or silicon wafers. This wafer-scale process is highly controlled to allow high-quality replication in batches. It is, however, quite expensive and time-consuming to progress from a lens design to a finished product, which hinders mass scalability, especially in cases of complicated designs.

Thermoset resins, such as epoxies, can be used when relatively simple lens shapes are involved, but their long curing times and the limited heat resistance of the cured epoxy remain problematic. Although techniques such as two-photon polymerization were developed for printing high-resolution micro-optics based on organic polymers, these solutions are limited in scalability, thermal stability, and/or refractive index range.

Micro-injection molding of MLAs has emerged as a transformative alternative, because it enables high-volume production of complex, precision micro-optical components with remarkable consistency, speed, scalability, and cost efficiency.

Micro-injection molding can also produce small batches of lenses for prototyping without the need to fabricate an entire wafer of lenses. It can mold lenses of almost any thickness, which liberates designers from restrictions of standard wafer thicknesses. And other micro-optical features, such as fiducial markers and pins for alignment, are generally easier to incorporate. Integrated features that facilitate passive optical alignment can also reducing assembly time and costs when compared with active alignment methods.

Polyetherimide (PEI), polymethyl methacrylate (PMMA), cyclo-olefin copolymer (COC), and polycarbonate (PC) are popular thermoplastic resins for injection molding large volumes of lenses and arrays with complex geometries. ULTEM resin, a PEI material, is a leading choice for MLAs used for applications such as pluggable transceivers and expanded beam connectors.

When manufacturers choose among these thermoplastic resins, assembly processes come into play. Optical elements can be exposed to high temperatures, for example, during reflow soldering. The material selected for these types of optics must be able to maintain dimensional accuracy under these thermal conditions. If the optical lens array is assembled prior to final PCB assembly, exposing the optics to temperatures as high as 260°C during reflow soldering, the thermoplastic resin used for the optics needs a heat deflection temperature of at least 260°C.

One challenge is that many thermoplastics deform or melt when exposed to 260°C temperatures and fall short of the new requirements for assembling CPO systems using reflow soldering. SABIC recently developed EXTEM RH1017UCL resin, a thermoplastic polyimide (PI) material, to address this challenge. Our near-infrared (NIR) transparent resin has a glass transition temperature well above 260°C and offers the industry a viable material for mass production of micro-optics for assembly using reflow soldering.

Stable light coupling with thermoplastic MLAs

SABIC’s PI material enables photonic system integration by providing a platform for high-efficiency optical coupling that performs well within extremely demanding industry tests such as hydro-aging and thermal shock tests. While MLAs themselves are passive optical elements, they play a vital role. By supporting precise, stable light coupling among fibers, waveguides, sensors, and photonic chips—even after surface mount technology (SMT) reflow—these MLAs remove a key barrier to the practical deployment of CPO systems because they increase the alignment tolerance during the packaging by expanding the light beam.

Moreover, the free-space optical interfaces enabled by these MLAs reduce mechanical stresses compared to direct physical fiber contact systems, which simplifies assembly processes and improves reliability.

Case study #1: Optical interconnects for copackaged optics

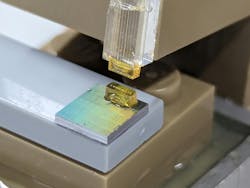

To demonstrate the feasibility and advantages of injection molded PI resin for optical interconnects in CPO, SABIC and Tyndall National Institute, a European research center for integrated ICT materials, devices, and systems, built surface couplers and edge couplers in a design where the MLA was packaged on a PIC with waveguide loops (see Figs. 1 and 2, respectively). For this design, the single-mode light beam was expanded between the fiber array unit and the PIC by using two MLAs.

SABIC’s new resin was used to fabricate the single-mode-compatible MLA, which consisted of eight lenses with a 250-µm pitch. These dimensions match standard eight-fiber connector arrays common in optical interfaces. The ability to produce these small parts with tight tolerances through injection molding marks a significant advancement by combining precision with the scalability of high-volume molding technology.

To demonstrate their utility, the MLAs were used to create beam-expanding optical elements. These elements were installed by using optically clear adhesives on each side of the optical connector interface to couple the fiber array via larger free-space beams to the PIC. This approach relaxes lateral alignment tolerances and reduces occlusion risk of contamination, such as dust particles.

The MLAs maintained their dimensions and optical performance—even after being subjected to multiple 260°C reflow soldering cycles. Such resilience is crucial for integration into SMT-based electronic assembly lines.

An efficient fiber-coupling structure is necessary for extreme high-density optical input and output. In general, two kinds of coupling structures exist: grating coupler and edge coupler. Each has its unique advantages and disadvantages; therefore, we built two types of demonstrators. Both demonstrators could be tested for pluggability using 50 break-and-make cycles, by bonding both fiber array and PIC to separate bricks.

Both setups achieved a stable eye-diagram at 25-gigabaud signaling rates and exhibited an average coupling loss of 2.2 dB per coupler across 50 make-and-break cycles. These results meet or exceed the practical requirements of many high-speed photonic interconnects.

Case study #2: Auto-alignment of MLAs

For most CPO packaging/alignment processes, including the demonstrators described above, optical adhesives such as epoxies are used. A process developed collaboratively with the Chip Integration Technology Center (CITC) uses an alternative interconnect technology for the optical alignment of MLAs. It involves metalizing distinct areas of the MLA that come in contact with compliant metal pads on the PIC. During the SAC305 reflow process, auto-alignment of the MLA with the PIC substrate occurs. This new optical packaging approach can replace standard epoxy adhesives, which have drawbacks such as lack of long-term stability and coefficient of thermal expansion (CTE) mismatches.

Upscale your optical array production

Upscaling production of optical arrays by adoption of micro-molding technology and high-heat specialty thermoplastics can promote high-volume, scalable production at an acceptable cost point. And injection molding further enables integration of features that facilitate passive optical alignment, which can reduce assembly time and costs compared with active alignment methods.

Other advantages of micro-molded optics include rapid prototyping to accelerate design innovation, and opportunities to standardize optical design and performance based on well-established material properties and molding technology. Overall, these advances help the optical communications and sensing industries transition more quickly to copackaged and onboard optics.

About the Author

Gabrie Hoogland

Gabrie Hoogland is chief scientist for SABIC Polymers, which is based in the Netherlands.

Kamil Gradkowski

Kamil Gradkowski is a senior researcher at Tyndall National Institute, Cork, in Ireland.